Plenary Speaker CCORE 2025: Ultra-Thin Vacuum Insulation for Deep Energy Savings

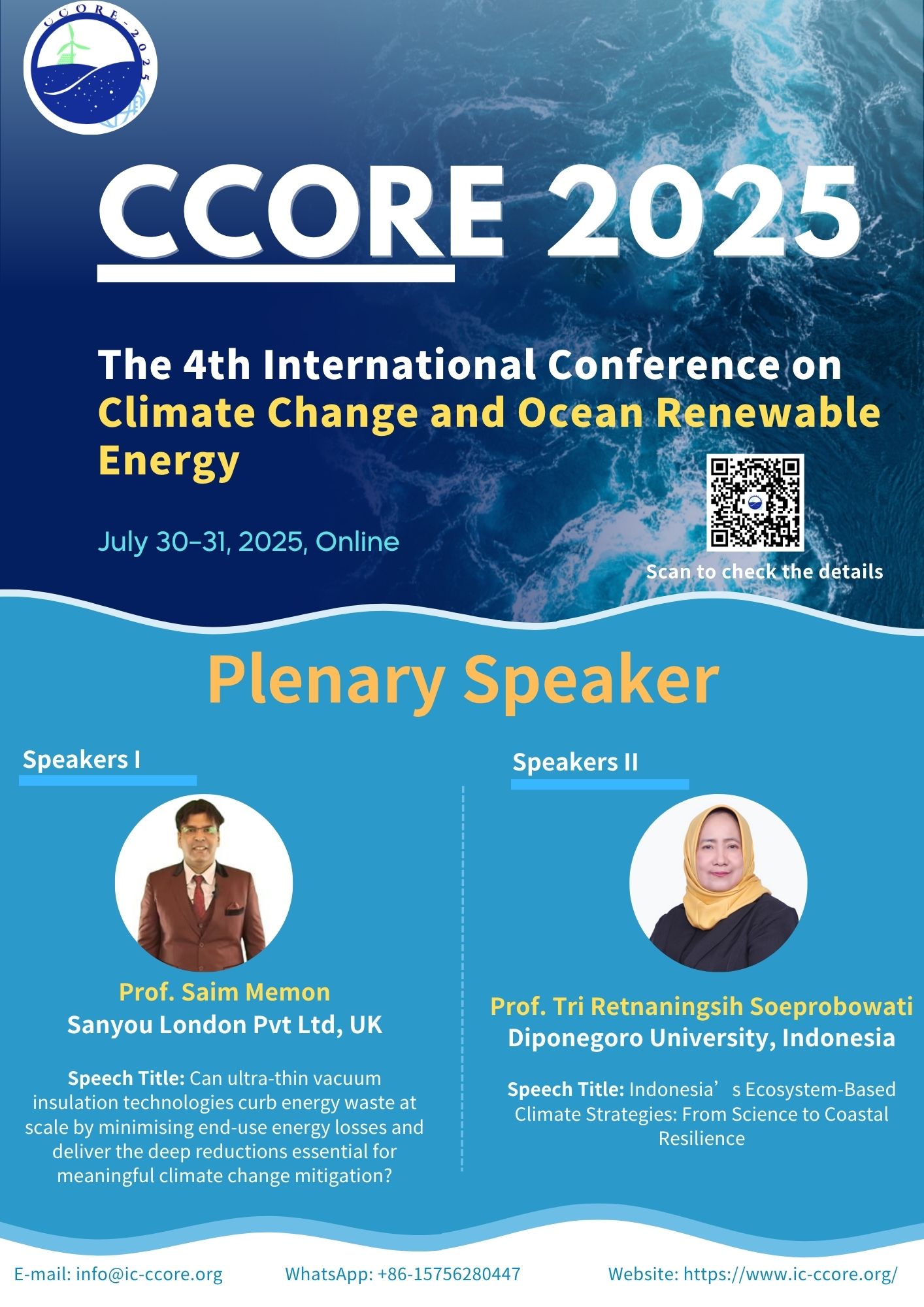

Event: 4th International Conference on Climate Change and Ocean Renewable Energy (CCORE 2025)

Dates: 30–31 July 2025

Format: Online

Role: Plenary speaker — Professor Saim Memon, CEO of Sanyou London

The plenary question

Can ultra-thin vacuum-insulation technologies curb energy waste at scale by minimising end-use losses and deliver the deep reductions essential for climate-change mitigation?

What was presented?

A harmonised suite of vacuum-insulation energy-saving technologies advanced to TRL 7–9 and designed to attack heat loss at its source across buildings, logistics and electro-thermal systems:

- Vacuum Insulation Panels (VIPs): 15 mm fibreglass-core panels at 2.5 mW m⁻¹ K⁻¹ (centre-of-panel U ≈ 0.16 W m⁻² K⁻¹); 25 mm fumed-silica panels at 4.5 mW m⁻¹ K⁻¹.

- Decorative Integrated VIP (DVIP): 30 mm façade cassettes, λ ≈ 7 mW m⁻¹ K⁻¹, designed to meet EN 13501-1 Class A1/A2 fire performance with freeze–thaw durability and ≥ 35-year aged performance.

- Vacuum-Insulated Wallpaper (VIW): ~4 mm laminate (tiles 200 × 200 mm), λ ≈ 5 mW m⁻¹ K⁻¹; on solid-brick walls in London, U-value ↓ up to 71 % and heating demand ↓ up to 30 %.

- Vacuum-Insulated Curtains (VIC): 7 mm assemblies, λ ≈ 13 mW m⁻¹ K⁻¹, U ≈ 1.87 W m⁻² K⁻¹; cooling-load ↓ ≥ 23 % in single-glazed offices (Riyadh).

- Vacuum-Insulated Heatable Curtains (VIHC): adds low-wattage radiant assist (≈ 1 kWh per three-hour cycle) for cold-climate comfort.

- Vacuum-Insulated Bag/Box (VIBB): maintains 2–8 °C for ~120 h at 40 °C ambient, cutting dry-ice/compressor reliance by ~80 %.

How it works: evacuating enclosed cores to ≤ 10 Pa suppresses convective and gaseous conductive transfer, delivering very low effective conductivity at millimetre-scale thickness.

Why does it matter?

Conventional fibrous or polymeric insulation struggles to reach sub-0.20 W m⁻² K without deep build-ups, space losses or fire-safety trade-offs. Ultra-thin vacuum insulation delivers high resistance with minimal depth, enabling retrofit in occupied buildings, constrained façades, glazing reveals, refrigeration cases and pipework. Life-cycle analyses presented indicate 15–60 kg CO₂e m⁻² avoided over 25 years, equating to 20–90 % end-use energy-waste abatement, depending on climate and use case.

Where can it be applied now?

- Buildings and estates: VIW for internal surfaces; DVIP for external façades; VIPs to close thermal bridges around reveals and services.

- Logistics and cold chain: VIBB for pharmaceuticals, vaccines and perishables—extended hold without powered refrigeration.

- Electro-thermal systems: VIC/VIHC for transparent façades; targeted VIPs for EV battery housings and AI/data-centre racks to stabilise temperatures and ease active-cooling duty.

Discussion points

- Demand-side first: thinner, faster retrofit flattens loads before adding generation or storage—vital for grid stability and tariff control.

- All-climate utility: retain heat in cold-arid regions; block ingress in hot-arid climates; reduce HVAC peaks and operating cost.

- Standards and delivery: certification and repeatable specifications are central to scaling adoption in public procurement and private portfolios.

Work with Sanyou London

- Spec sheets, samples and pilots: VIW, VIP, DVIP, VIC/VIHC and VIBB for retrofit and new-build.

- Partnerships: universities, developers, architects, contractors, local suppliers and distributors seeking space-efficient energy savings.

Contact: Visit www.sanyoulondon.com or reach Sanyou London Customer Service.

Media & speaking enquiries: Professor Saim Memon

Keywords: Vacuum insulation technologies; Ultra-thin VIP; Building-retrofit energy saving; End-use heat-loss reduction; Cold-chain thermal management; Climate-change mitigation.

Share