To request latest version of the product catalogue and sales price,

please reach out to our Customer Service Team at info@sanyoulondon.com

Advanced Vacuum Insulation Solution for Maintaining Freshness over

Extended Periods in Temperature-Sensitive Transport and Storage.

Ideal for Medical, Food, Chemical, and Logistics Applications

with Adaptive Energy-Efficient Performance

General Product Description

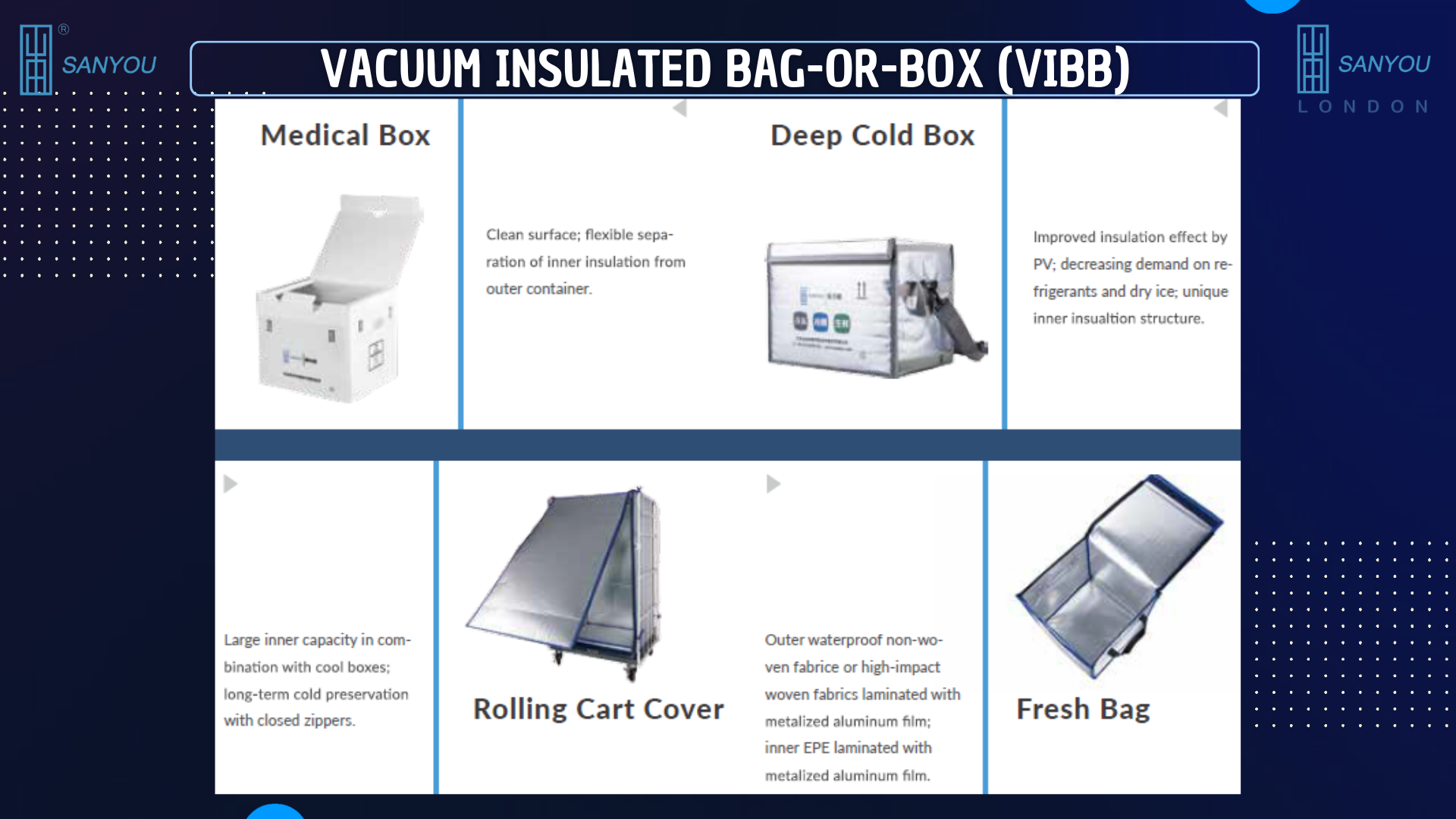

Ü The Vacuum Insulated Bag-or-Box (VIBB) is a significant advancement in the application of flexible vacuum insulation panels (VIPs) and with the use of PU (Polyurethane) to improve load bearing capacity, configured as boxes, bags, or carts. These are designed to maintain the internal temperature, either cold or hot, of the contained materials for extended periods without the need for ice, refrigeration, or electricity. This innovation is particularly useful in various applications, including the transportation and temporary storage involved in cold chain logistics, as well as in the handling of special pharmaceuticals, chemicals, fresh and frozen foods, and other products requiring long-duration temperature control. Recognizing the diverse range of applications, we have developed and differentiated the VIBB into four distinct types: (1) Medical Box, (2) Deep Cold Box, (3) Rolling Cart Cover, and (4) Fresh Bag. Each type of VIBB boasts unique characteristics and specifications tailored to meet specific requirements.

Key Characteristics

Ü Cold-Arid Applications

l In cold-arid regions, maintaining warmth is crucial for many applications, from emergency medical services to the transport of temperature-sensitive goods that could freeze and become unusable or lose their efficacy in extremely cold conditions.

l Medical Box: In such environments, the Medical Box variant of VIBB is essential for transporting temperature-sensitive pharmaceuticals, vaccines, and medical supplies that require a strictly controlled environment to remain effective for a period of time. This is particularly critical in remote or rural areas where access to conventional heating or electrical power may be limited.

l Fresh Bag: The Fresh Bag can be used to protect perishable foods or biological samples from freezing, ensuring that they remain fresh and viable over long distances or periods without the need for powered heating systems for long-hours.

Ü Hot-Arid Applications

l In hot-arid regions, the challenge is to keep contents cool to prevent spoilage or degradation. Here, the VIBB technology proves to be equally beneficial.

l Deep Cold Box: This variant is ideal for transporting frozen goods, such as food or biological specimens, ensuring they remain frozen or at a controlled low temperature for a period of time without the need for electrically powered refrigeration, which can be particularly advantageous in areas with unreliable power infrastructure.

l Rolling Cart Cover: Designed to cover and insulate larger carts or pallets, this VIBB is perfect for outdoor markets, food delivery services, or transporting larger quantities of perishable goods in hot climates, preventing spoilage and heat damage during transport or temporary storage.

Ü Cross-Environmental Applications

l The versatility of VIBB extends to applications relevant in both hot and cold arid environments, demonstrating its wide utility range.

l Emergency Response and Disaster Relief: In disaster-struck regions where infrastructure is compromised, VIBB technology can be crucial for transporting medical supplies, food, and water, maintaining their integrity until they reach those in need.

l Agriculture and Food Security: For agricultural sectors in arid regions, VIBB can play a role in protecting harvested produce from extreme temperatures during transport or storage, contributing to food security.

l Scientific Research and Environmental Monitoring: For scientists working in extreme conditions, VIBB offers a solution for transporting samples, equipment, and research materials safely across different temperature zones without compromising their integrity.

Key Highlights

Ü The development of VIBB technology and its diversification into tailored solutions for your specific needs highlights its importance in addressing the logistical and practical challenges posed by extreme temperatures in both cold-arid and hot-arid countries.

Ü Its ability to maintain temperature stability for long durations without reliance on external power sources offers a sustainable, efficient solution with broad implications for healthcare, food security, environmental management, and beyond.

Medical Box Description

Ü The Medical Box, variant of the Vacuum Insulated Bag-or-Box (VIBB), is designed with plastic protective film on the outer surface, fumed silica VIP with PU insulation with hollow board protective box for outside to cater to a wide range of medical storage and transportation needs. It is available in various sizes, capacities, and weights to accommodate different requirements.

Ü This flexibility ensures that whether it’s for small, sensitive medical samples or larger quantities of pharmaceuticals, there’s a Medical Box suited to the task. Each box is meticulously engineered to maintain the required temperature range for the safe transport of medical items, without the need for external power sources like electricity or ice.

Ü The diverse size options mean that healthcare providers can choose a box that fits their specific volume needs, while the varying capacities ensure that both lightweight and heavier medical supplies can be securely and efficiently transported. The weight variations in the Medical Box lineup are designed with user convenience and transportation logistics in mind, ensuring that each box is as lightweight as possible while still providing robust protection and thermal insulation for its contents.

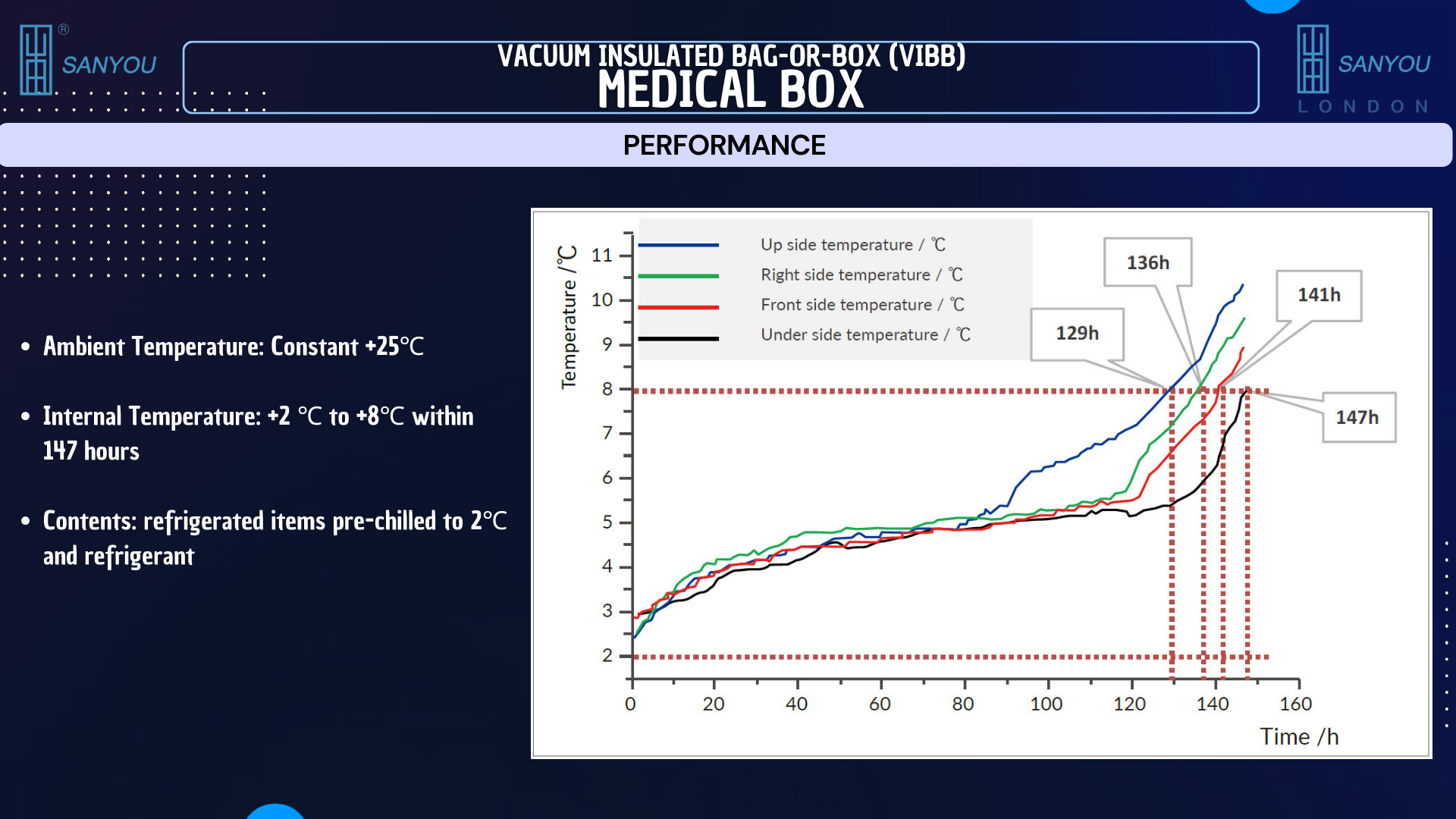

Medical Box Performance

Medical Box Applications

Ü The Medical Box, a specialized adaptation of the Vacuum Insulated Bag-or-Box (VIBB) technology, is meticulously designed to cater to the rigorous demands of transporting and temporarily storing temperature-sensitive pharmaceuticals and chemicals. This innovation is pivotal in sectors where maintaining the integrity of products is not just crucial for their efficacy but also for ensuring safety and compliance with regulatory standards.

Ü Special Pharmaceuticals

In the pharmaceutical industry, the stability of many medications, vaccines, and biological products is temperature-dependent. The Medical Box serves as an essential tool in various scenarios.

l Vaccine Distribution: Ensuring vaccines are kept at precise temperatures to preserve their effectiveness until they reach vaccination centres, clinics, and remote locations.

l Clinical Trials: Transporting investigational medicines between manufacturing sites, research laboratories, and trial sites while maintaining the required temperature conditions to ensure trial integrity.

l Specialty Pharmacy Services: Delivering personalized medications, such as biologics, that require strict temperature control directly to patients’ homes or healthcare providers.

Ü Special Chemicals

The precise and controlled environment of the Medical Box is also ideal for the transportation and temporary storage of sensitive chemicals used in medical research, diagnostics, and treatment, including:

l Laboratory Reagents: Transporting chemical reagents and enzymes used in research and diagnostic laboratories that require specific temperature conditions to remain active and effective.

l Chemical Standards for Calibration: Ensuring that chemical standards used in medical and research instrumentation are transported without temperature fluctuations to maintain their accuracy and reliability for calibrations.

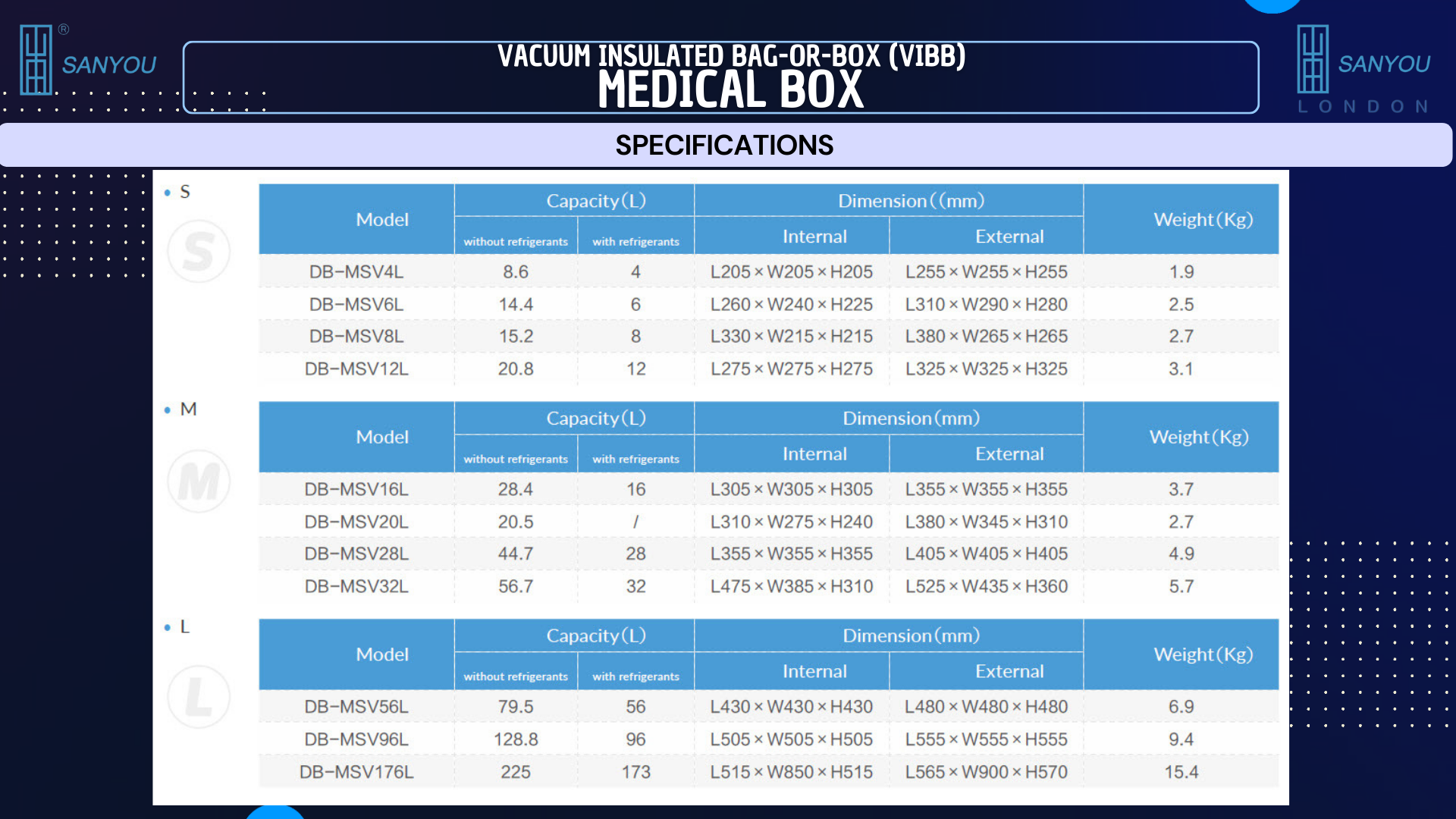

Medical Box Specifications

Deep Cold Box Product Description

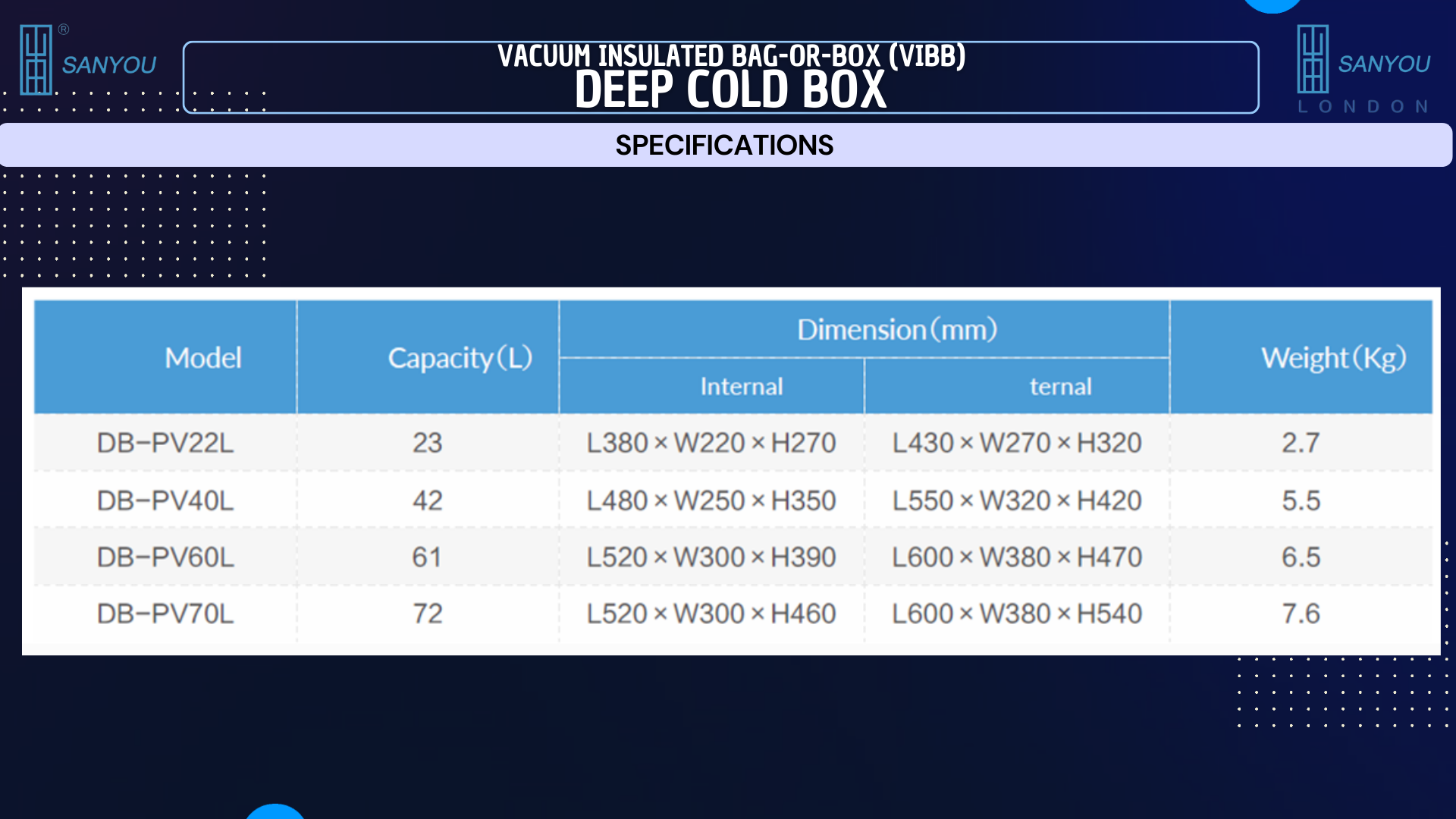

Ü The Deep Cold Box, crafted from Vacuum Insulated Bag-or-Box (VIBB) materials, is available in both foldable and non-foldable variants. These boxes are engineered with standard dimensions, offering a range of sizes, capacities, and weights to meet various storage needs. Each Deep Cold Box features a sealed Velcro closure at the top and includes a special mesh bag designed for securing specimens, materials, or refrigerants.

Ü A standout feature of the Deep Cold Box is its integration of real-time temperature monitoring and a positioning system, ensuring the contents’ temperature is constantly tracked and the box’s location is known, enhancing the security and reliability of transporting sensitive items. The boxes are constructed with an outer layer of ultra-high strength aluminium film, enhancing their durability and thermal reflection properties. The core of the box incorporates an advanced Polyurethane Vacuum Insulation Panel (PU-VIP) structure, which not only enhances the box’s insulation properties but also significantly increases its load-bearing capacity. The foldable version of the Deep Cold Box offers additional convenience, making it easier to store and transport when not in use.

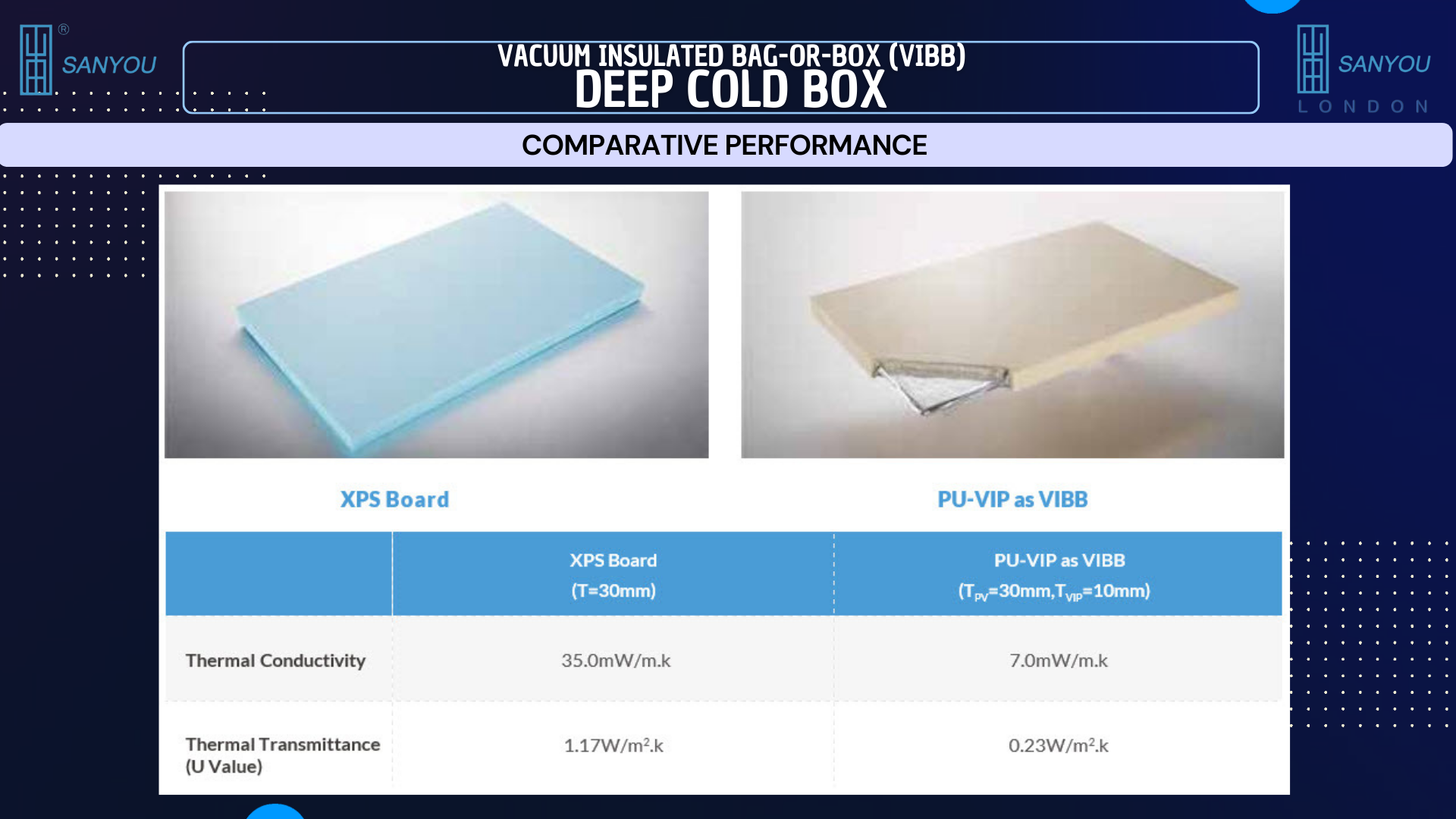

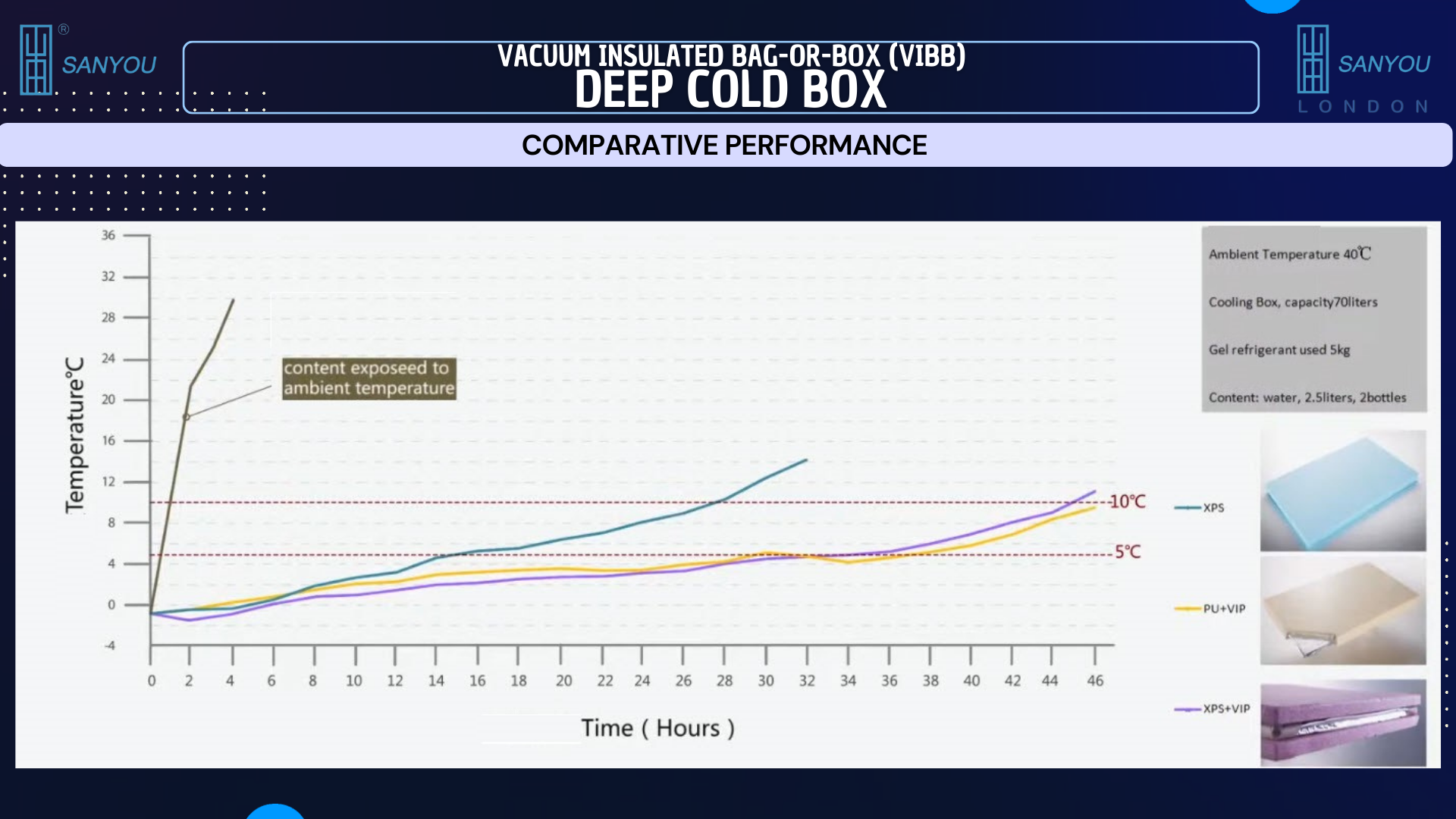

Ü Primarily designed for the prolonged temperature-controlled storage of frozen foods, the Deep Cold Box leverages the superior insulation properties of its materials. Specifically, the thermal conductivity of the PU-VIP, with 30 mm of PU and 10 mm of VIP, is measured at 7mW/(mK). In comparison, a standard Extruded Polystyrene (XPS) insulation panel with a 30 mm thickness has a thermal conductivity of 35mW/(mK). This means that the PU-VIP used in the Deep Cold Box is 5 times more efficient in terms of thermal insulation compared to XPS panels, offering superior performance for maintaining low temperatures over extended periods.

Deep Cold Box Material Comparison

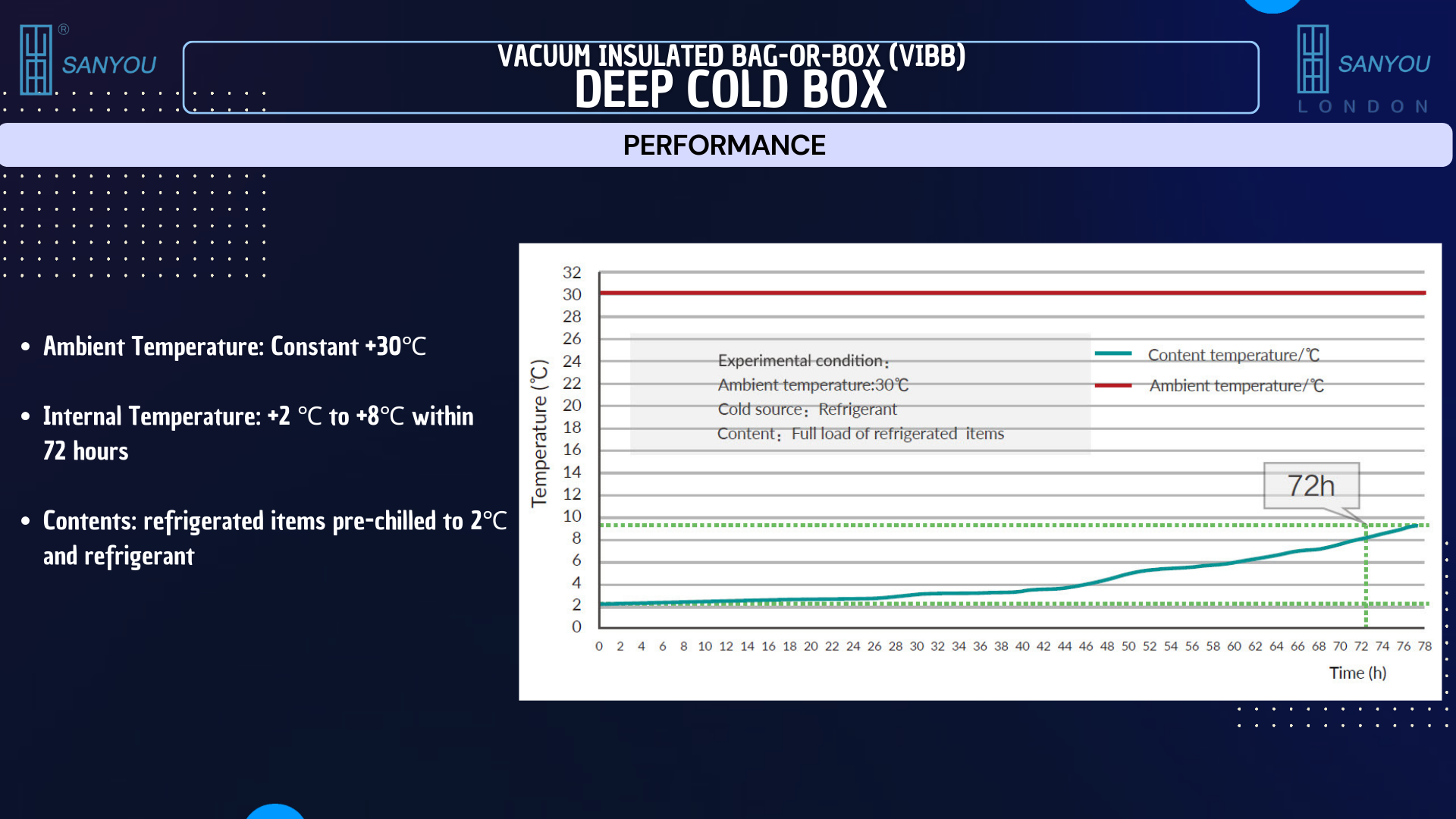

Deep Cold Box Performance

Deep Cold Box Applications

Expanding on its applications, the Deep Cold Box can be adapted for use in a variety of other contexts such as follows.

Ü Fresh and Frozen Food Logistics

The Deep Cold Box is integral to the food industry, ensuring that fresh and frozen foods are transported under optimal conditions. This is crucial for maintaining the nutritional value, taste, and safety of food products from the point of origin to the consumer. The Deep Cold Box can be used by:

l Food Distributors and Retailers: For the delivery of frozen products like ice cream, seafood, and prepared meals to retail locations, ensuring products remain frozen and do not thaw prematurely.

l Catering Services: To transport ingredients and prepared dishes to event locations, preserving the freshness and quality of the food.

l Farmers and Fisheries: For transporting perishable produce and seafood to markets or processing facilities, reducing spoilage and waste.

Ü Special Chemicals and Pharmaceuticals

The precision temperature control of the Deep Cold Box makes it indispensable for the transportation and storage of special chemicals and pharmaceuticals, which often require low-temperature environments to retain their efficacy and stability. Applications include:

l Pharmaceutical Distribution: For vaccines, insulin, and other temperature-sensitive medications that need to be stored at low temperatures during transit to pharmacies, hospitals, and clinics.

l Laboratories and Research Institutions: For transporting chemical reagents and biological samples that require controlled temperatures to prevent degradation or loss of viability.

l Chemical Manufacturing: In transporting specialty chemicals that are temperature-sensitive, ensuring they remain stable and do not deteriorate or react undesirably during transit.

Ü Long-Duration, Low-Temperature Product Delivery

The Deep Cold Box is also tailored for the extended delivery of low-temperature products, catering to industries and services where long-haul transportation is common, and temperature integrity is non-negotiable. This includes:

l E-Commerce: For online businesses that ship frozen foods, gourmet items, or temperature-sensitive products directly to consumers, ensuring that products arrive in optimal condition.

l Biomedical Transport: For the safe transport of biological specimens, organs for transplant, or stem cells, which must be kept at low temperatures for preservation during long-distance deliveries.

l Specialty Beverages: For artisanal brewers and vintners who require controlled temperature conditions for the distribution of specialty beers, wines, and spirits to maintain flavour profiles and quality.

In every application, the Deep Cold Box stands out for its ability to ensure the integrity, quality, and safety of its contents, making it an essential tool in industries where temperature control is not just a requirement, but a critical factor for success.

Deep Cold Box Specifications

Rolling Cart Cover Description

Ü The Rolling Cart Cover, a variant of the Vacuum Insulated Bag-or-Box (VIBB), is a versatile, large-sized vacuum insulation solution designed for the dual-purpose task of maintaining both cold and warm temperatures during the transportation of fresh and frozen foods, making it particularly suitable for chain stores. This innovation extends beyond traditional applications, offering a range of standard dimensions, capacities, and weights to meet diverse logistical needs. It has large inner capacity, long-term cold preservation with closed zippers, solid steel frame with good load-bearing performance is for rolling cart body, the bottom moving roller design is convenient for turnover and transportation.

Ü In addition to its primary function, the Rolling Cart Cover features a sealed Velcro closure at the front for secure sealing and can be customized with advanced features such as real-time temperature monitoring and a positioning system, according to specific user requirements. This customization ensures that the contents remain at the desired temperature throughout transportation and storage, with the added benefit of being able to track the cart’s location in real-time.

Ü The construction of the Rolling Cart Cover incorporates special material compositions, including an outer surface crafted from ultra-high strength aluminium film. This choice of materials not only enhances the cover’s durability but also its reflective properties, contributing to its insulative efficiency. The base of the cover is fortified with an improved Polyurethane Vacuum Insulation Panel (PU-VIP) structure, which reinforces the cover’s load-bearing capabilities and insulation performance, making it an ideal choice for the extended, temporary storage of frozen foods.

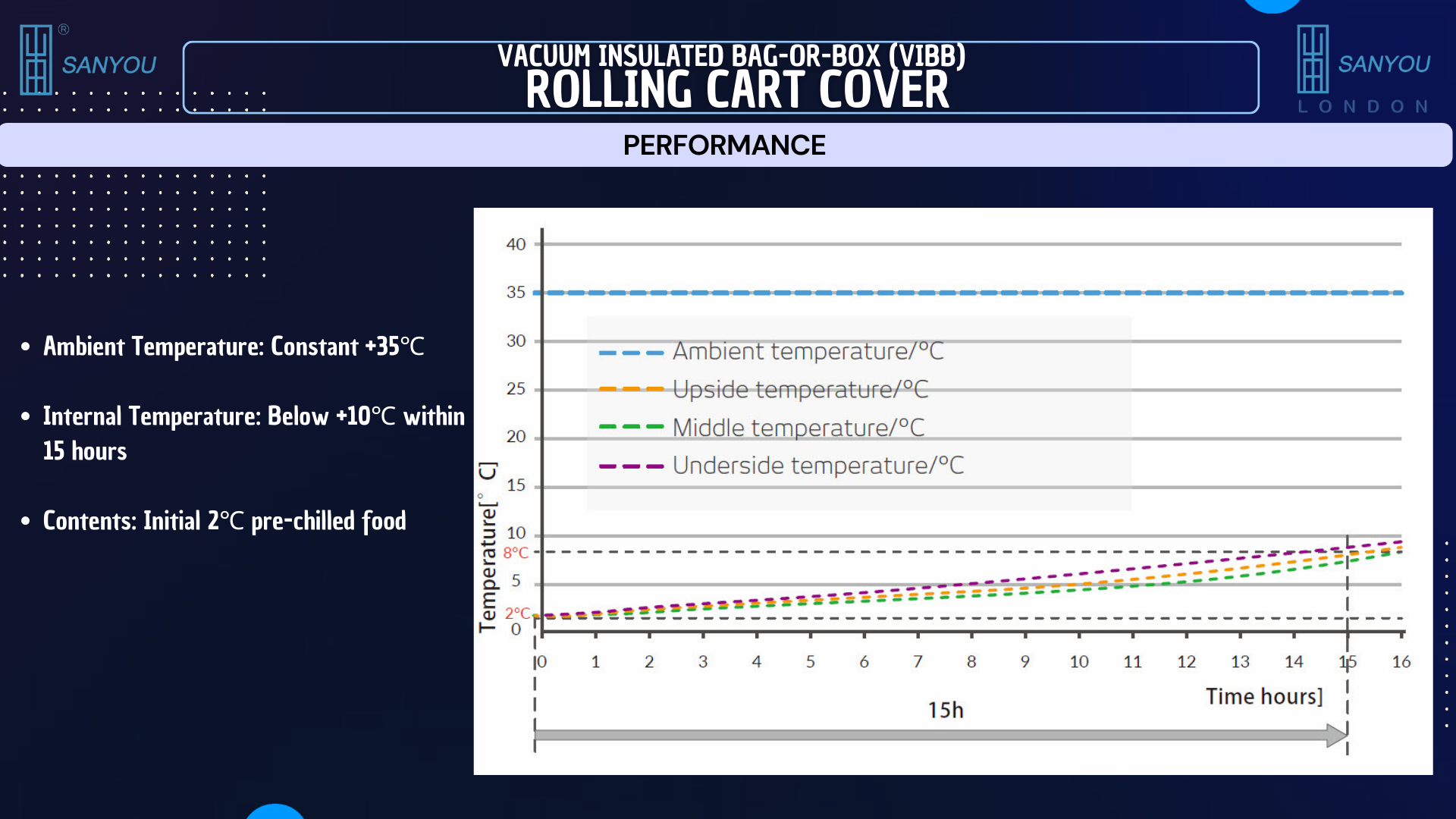

Rolling Cart Cover Performance

Rolling Cart Cover Applications

Ü Expanding on its applications, the Rolling Cart Cover can be adapted for use in a variety of other contexts such as follows.

l Pharmaceutical Transport: Its temperature control capabilities make it ideal for transporting temperature-sensitive pharmaceuticals, ensuring that medications and vaccines are kept at optimal temperatures during transit.

l Catering and Event Management: The Rolling Cart Cover can be used to transport hot and cold dishes to event venues, maintaining the desired temperature until serving.

l Agricultural Produce Transport: It can serve as a mobile storage unit for farmers and grocers, preserving the freshness of fruits, vegetables, and other perishables during transportation from farm to market or distribution centres.

l Emergency and Disaster Relief: In situations requiring rapid deployment of food, water, or medical supplies to affected areas, the Rolling Cart Cover can ensure that these critical items are maintained at appropriate temperatures, regardless of external conditions.

Ü By extending its utility beyond the food industry to sectors like pharmaceuticals, event management, agriculture, and emergency relief, the Rolling Cart Cover showcases its adaptability and the broad potential of VIBB technology in various fields.

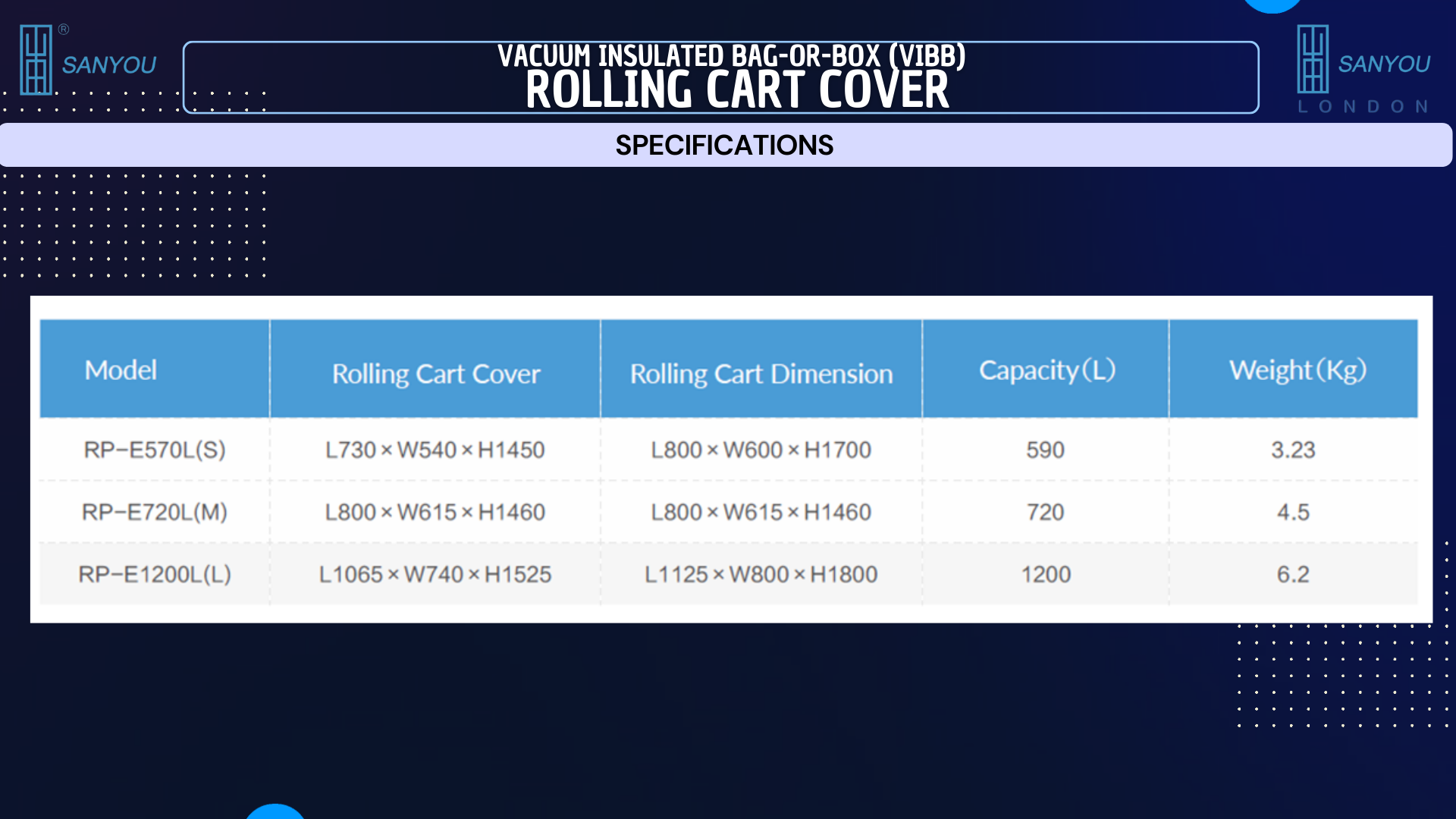

Rolling Cart Cover Specifications

Fresh Bag Description

Ü The Fresh Bag, a pioneering addition to the Vacuum Insulated Bag-or-Box (VIBB) range, tailored for modern, on-the-go lifestyles and demanding food logistics. This innovative bag combines the cutting-edge technology of vacuum insulation with the convenience and flexibility needed in today’s fast-paced world. Available in a variety of sizes and designs, the Fresh Bag is engineered to cater to diverse needs, from individual food deliveries to bulk transport of perishables.

Ü Design and Features

l Soft, Cushioned Material: Each Fresh Bag is crafted from soft materials that act as a cushion, providing added protection for the contents against bumps and jostles during transit.

l Foldability and Space Efficiency: Designed with practicality in mind, the Fresh Bag can be easily folded when not in use, making it a space-saving solution ideal for tight storage spaces and minimalistic living.

l Lightweight and Portable: The emphasis on creating a lightweight bag ensures that it is easy to carry, enhancing user comfort and convenience, whether it’s a short trip to the farmer’s market or a longer delivery route.

The Fresh Bag redefines the standards for portable food storage and transportation, marrying innovation with functionality to meet the dynamic needs of food delivery professionals, culinary enthusiasts, and anyone in need of reliable, temperature-controlled storage on the move.

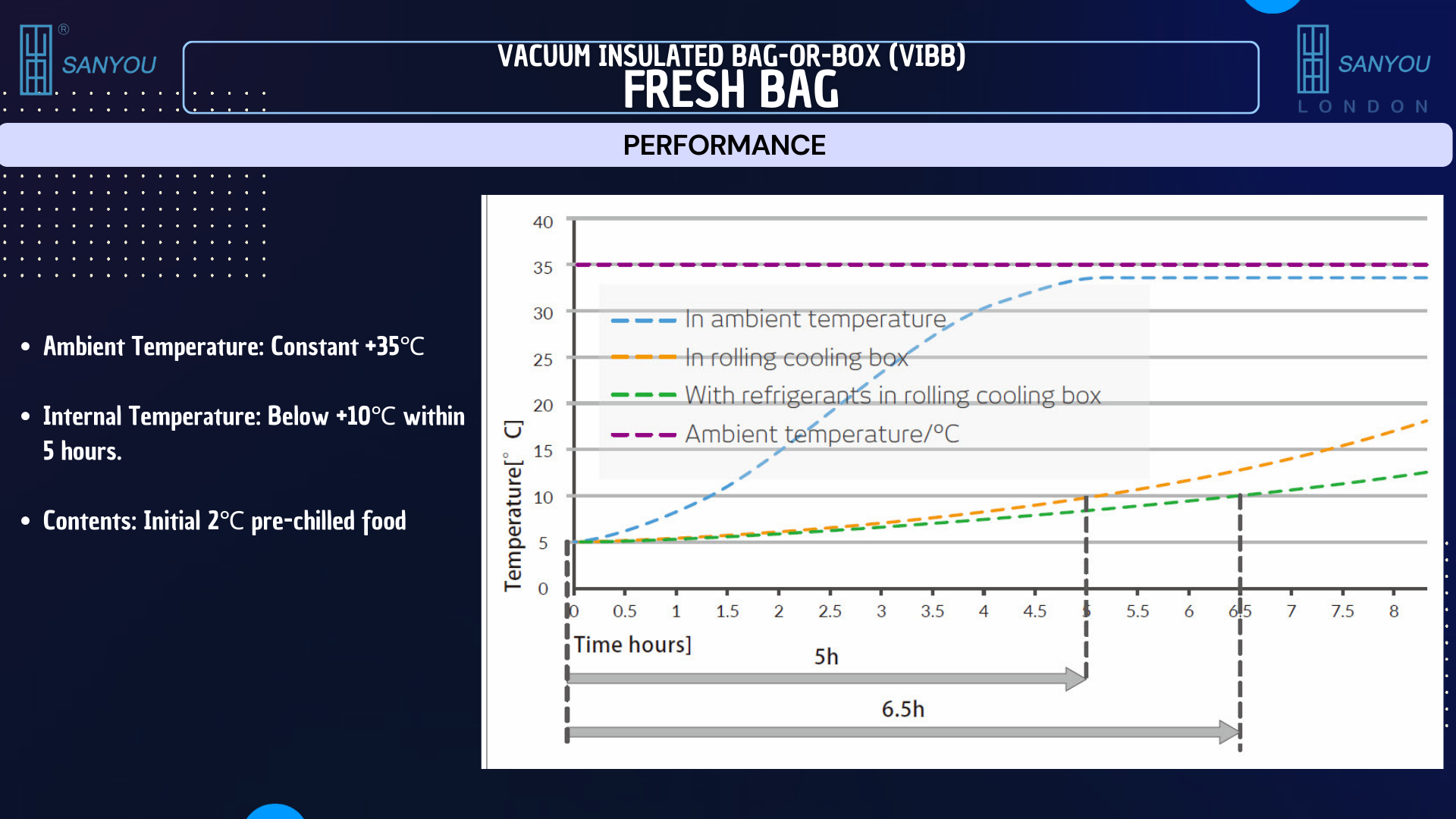

Fresh Bag Performance

Fresh Bag Applications

Ü Food Delivery Services: The Fresh Bag is an indispensable tool for delivery drivers and couriers, ensuring that food deliveries, from hot pizzas to cold sushi platters, arrive at their destination in optimal condition, preserving taste, temperature, and freshness.

Ü Transportation and Storage of Fresh and Chilled Foods: Its superior insulation properties make the Fresh Bag ideal for transporting and storing a wide range of fresh and chilled foods. This includes:

Ü Farm-to-Table Deliveries: For small-scale farmers or community-supported agriculture (CSA) programs, the Fresh Bag provides an effective way to deliver fresh produce directly to consumers, maintaining the freshness and quality from farm to doorstep.

Ü Outdoor Events and Picnics: Perfect for keeping food fresh and drinks chilled during outdoor gatherings, picnics, or beach outings, ensuring that every meal served is as fresh as intended.

Ü Personal Grocery Shopping: The Fresh Bag is a great companion for shoppers looking to keep perishable items like dairy, meat, and frozen goods in optimal condition during the journey home, especially in warmer climates or during summer months.

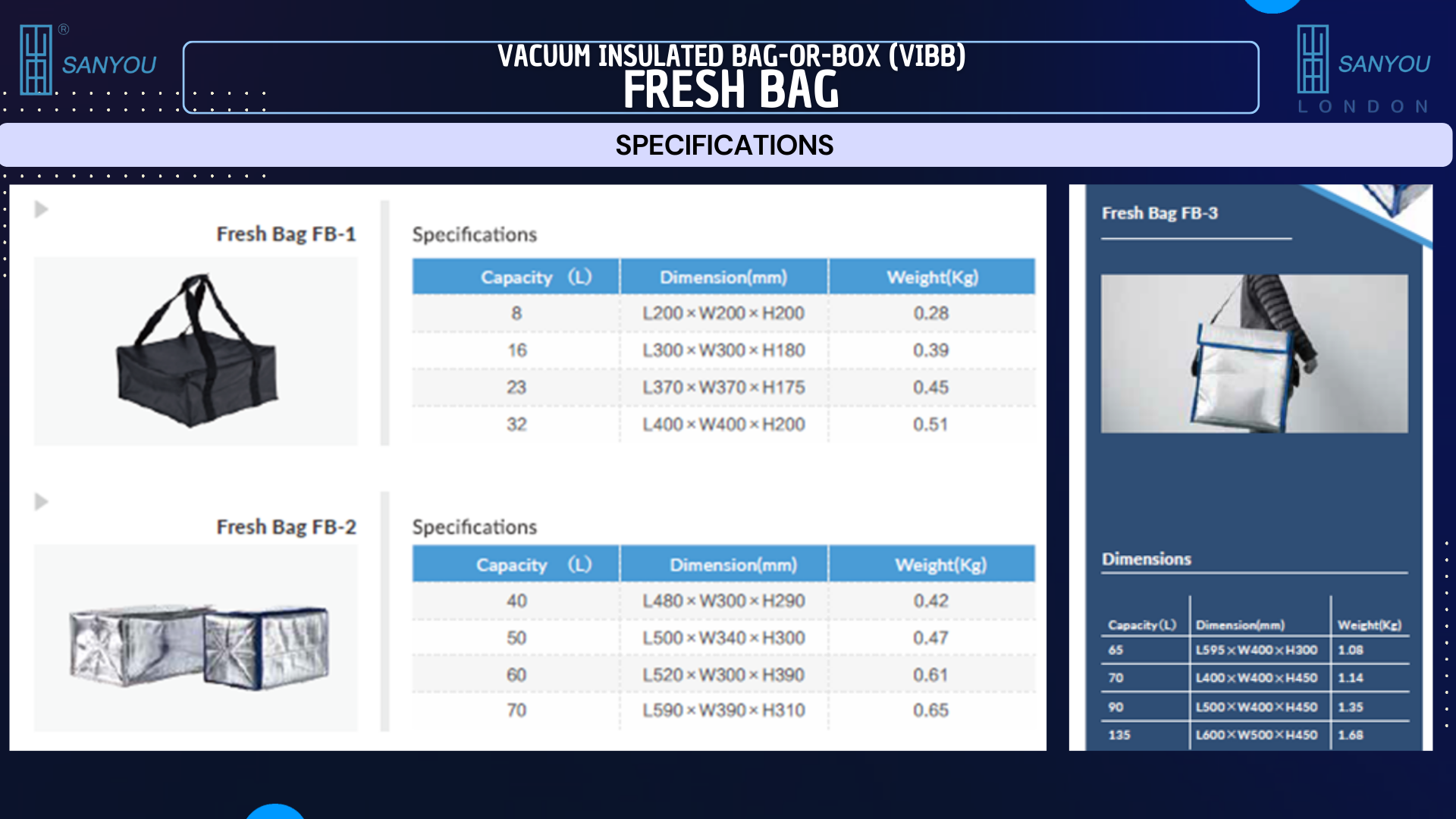

Fresh Bag Specifications

Video

FAQs

FAQs about VIBB Medical Box

What is the Medical Box and its primary function?

The Medical Box is a specialized version of the Vacuum Insulated Bag-or-Box (VIBB), designed with a plastic protective film, fumed silica VIP with PU insulation, and an external hollow board protective box. It's intended for the secure transportation and storage of temperature-sensitive medical and chemical products, maintaining specific temperature ranges without external power sources. However, due to the sensitivity of the medical and chemical products, additional temperature-controlled mechanism and refrigeration is required.

In what sizes and capacities is the Medical Box available?

The Medical Box comes in a variety of sizes, capacities, and weights to accommodate different needs, from small medical samples to larger quantities of pharmaceuticals. This flexibility ensures there's a suitable option for various medical and pharmaceutical requirements.

How does the Medical Box maintain temperature, and what are its performance capabilities?

The Medical Box maintains an internal temperature of +2℃ to +8℃ for up to 147 hours at an ambient temperature of +25℃, ideal for the transport of pre-chilled refrigerated items and refrigerants. It achieves this through advanced vacuum insulation technology without needing electricity or ice.

Can the Medical Box be used for vaccine distribution?

Yes, but it can be part of the whole vaccine distribution as each has different temperature requirement, the Medical Box only maintains the temperature for a period of time and is essential part of the overall distributing vaccines, maintaining precise temperatures to preserve their efficacy until they reach their destination, including vaccination centres, clinics, and remote locations.

Is the Medical Box suitable for transporting investigational medicines for clinical trials?

The Medical Box ensures investigational medicines are transported between manufacturing sites, research laboratories, and trial sites while maintaining required temperature conditions for a certain period of time, and depends on various environmental conditions such as humidity and ambient temperatures.

How does the Medical Box cater to specialty pharmacy services?

The Medical Box delivers personalized medications and itself it provides insulation only but additional measures are necessary, such as biologics, which require strict temperature control, directly to patients' homes or healthcare providers, ensuring the medication's effectiveness and safety.

Are there any special considerations for transporting sensitive chemicals in the Medical Box?

Yes, the controlled environment of the Medical Box is ideal for transporting and storing sensitive chemicals used in medical research, diagnostics, and treatment, ensuring they remain active and effective by maintaining specific temperature conditions.

FAQs about VIBB Deep Cold Box

What is the Deep Cold Box and how does it work?

The Deep Cold Box DB-PV is a highly efficient storage and transportation solution, part of the Vacuum Insulated Bag-or-Box (VIBB) series, designed to maintain low temperatures for extended periods. It is available in both foldable and non-foldable variants and features a sealed Velcro closure, a special mesh bag for securing items, and advanced PU-VIP insulation for superior thermal efficiency.

Can the Deep Cold Box maintain temperatures for long-duration transport?

Yes, the Deep Cold Box is engineered to maintain an internal temperature of 2-8℃ for up to 72 hours in an ambient environment of +30℃, making it ideal for long-duration transportation of temperature-sensitive items.

What makes the Deep Cold Box unique in terms of construction?

The Deep Cold Box features a durable outer layer of ultra-high strength aluminium film and an inner core of advanced Polyurethane Vacuum Insulation Panel (PU-VIP), enhancing both its insulation properties and load-bearing capacity. Its design includes real-time temperature monitoring and a positioning system for enhanced security and reliability.

How does the thermal insulation of the Deep Cold Box compare to standard insulation panels?

The PU-VIP insulation used in the Deep Cold Box, with a thermal conductivity of 7mW/(mK), is 5 times more efficient than standard Extruded Polystyrene (XPS) insulation panels, which have a thermal conductivity of 35mW/(mK), providing superior performance in maintaining low temperatures.

What are the primary applications of the Deep Cold Box?

The Deep Cold Box is versatile, ideal for the food industry to transport fresh and frozen foods, the pharmaceutical and chemical industries for transporting sensitive materials, and for long-haul transportation of low-temperature products in sectors like e-commerce and biomedical transport.

Is the Deep Cold Box suitable for the transportation of pharmaceuticals?

Absolutely. The Deep Cold Box's maintain temperature control for a period of time that can be helpful in transporting vaccines, insulin, and other temperature-sensitive medications, ensuring they remain effective during transit to pharmacies, hospitals, and clinics.

Can the Deep Cold Box be used for fresh and frozen food logistics?

Yes, the Deep Cold Box ensures that fresh and frozen foods are transported under optimal conditions, maintaining their nutritional value, taste, and safety, making it suitable for food distributors, retailers, catering services, and more.

How does the Deep Cold Box support the delivery of specialty beverages?

The Deep Cold Box provides controlled temperature conditions essential for the distribution of specialty beers, wines, and spirits by artisanal brewers and vintners, helping maintain flavour profiles and quality during transport.

Is the Deep Cold Box easy to store and transport when not in use?

Yes, the foldable version of the Deep Cold Box offers additional convenience for storage and transportation, making it a space-saving solution when not in use.

FAQs about VIBB Rolling Cart Cover

What is the Rolling Cart Cover?

The Rolling Cart Cover is a large-sized, versatile vacuum insulation solution that's part of the Vacuum Insulated Bag-or-Box (VIBB) series. It's designed to maintain both cold and warm temperatures for the transportation of fresh and frozen foods, making it ideal for chain stores and various other applications.

How does the Rolling Cart Cover maintain temperatures?

The Rolling Cart Cover is capable of maintaining an internal temperature below +10℃ for up to 15 hours in an ambient environment of +35℃, thanks to its high-quality insulation materials, including an outer surface of ultra-high strength aluminium film and a base fortified with PU-VIP (Polyurethane Vacuum Insulation Panel).

What features does the Rolling Cart Cover offer?

Beyond its insulative properties, the Rolling Cart Cover features a sealed Velcro closure for secure sealing, a solid steel frame for excellent load-bearing performance, and bottom rollers for easy transport. It can also be customized with advanced options like real-time temperature monitoring and a positioning system to track the cart's location in real time.

Can the Rolling Cart Cover be used for transporting pharmaceuticals?

Yes, the temperature control capabilities of the Rolling Cart Cover make it suitable for transporting temperature-sensitive pharmaceuticals, ensuring that medications and vaccines remain at optimal temperatures during transit.

Is the Rolling Cart Cover suitable for catering and event management?

Absolutely. The Rolling Cart Cover can be used to transport both hot and cold dishes to event venues, maintaining the desired temperatures until serving time, making it a valuable asset for catering and event management professionals.

How can the Rolling Cart Cover assist in agricultural produce transport?

The Rolling Cart Cover serves as an efficient mobile storage unit for farmers and grocers, preserving the freshness of fruits, vegetables, and other perishables during transportation from the farm to the market or distribution centres.

Can the Rolling Cart Cover be used in emergency and disaster relief efforts?

Yes, the Rolling Cart Cover is an excellent tool for emergency and disaster relief scenarios, ensuring the maintenance of appropriate temperatures for critical items like food, water, or medical supplies, regardless of external conditions.

What makes the Rolling Cart Cover different from traditional transportation solutions?

The Rolling Cart Cover stands out due to its dual-purpose temperature maintenance, durable construction, and the ability to be customized with real-time tracking features, making it a more versatile and reliable solution than traditional transportation methods.

How does the Rolling Cart Cover's load-bearing performance benefit users?

With a solid steel frame and improved PU-VIP structure, the Rolling Cart Cover provides excellent load-bearing performance, ensuring that it can handle significant weights while still maintaining temperature control, adding to its utility in a wide range of applications.

FAQs about VIBB Fresh Bag

What is the Fresh Bag?

The Fresh Bag is a cutting-edge addition to the Vacuum Insulated Bag-or-Box (VIBB) series, designed for modern, on-the-go lifestyles and demanding food logistics. It uses vacuum insulation technology to maintain temperature control, making it perfect for individual food deliveries and the bulk transport of perishables.

What are the key features of the Fresh Bag?

Key features include its soft, cushioned material that protects contents during transit, its foldability for space efficiency, and its lightweight design for easy portability. These features combine to offer a convenient and reliable solution for temperature-controlled storage on the move.

How does the Fresh Bag perform in maintaining temperatures?

The Fresh Bag is designed to maintain an internal temperature below +10℃ for up to 5 hours when combined with rolling carts and up to 6.5 hours when combined with refrigerants, in an ambient temperature of +35℃. This ensures that pre-chilled food starting at 5℃ remains fresh and at a safe temperature.

What applications is the Fresh Bag suited for?

The Fresh Bag is ideal for food delivery services, ensuring optimal condition for a variety of foods during transit. It's also great for transporting and storing fresh and chilled foods for farm-to-table deliveries, outdoor events, picnics, and personal grocery shopping, maintaining freshness and quality.

Can the Fresh Bag be used for professional food delivery services?

Yes, the Fresh Bag is an indispensable tool for delivery drivers and couriers, allowing for the safe transport of hot and cold food items, ensuring they arrive at their destination tasting great and at the right temperature.

Is the Fresh Bag suitable for farm-to-table deliveries?

Absolutely. The Fresh Bag provides small-scale farmers and CSA programs with an effective solution for delivering fresh produce directly to consumers, preserving the freshness and quality from farm to doorstep.

How does the Fresh Bag contribute to outdoor events and picnics?

The Fresh Bag is perfect for outdoor events and picnics, keeping food fresh and drinks chilled, ensuring that every meal served is as enjoyable and fresh as intended.

Can the Fresh Bag help in personal grocery shopping?

The Fresh Bag is a great companion for personal grocery shopping, especially useful for keeping perishable items like dairy, meat, and frozen goods in optimal condition during the journey home, particularly in warmer climates or during summer months.

How does the Fresh Bag's design enhance user convenience?

The design focuses on user convenience by being soft and cushioned to protect contents, foldable to save space when not in use, and lightweight to ensure it's easy to carry for various transportation needs.