To request latest version of the product catalogue and sales price,

please reach out to our Customer Service Team at info@sanyoulondon.com

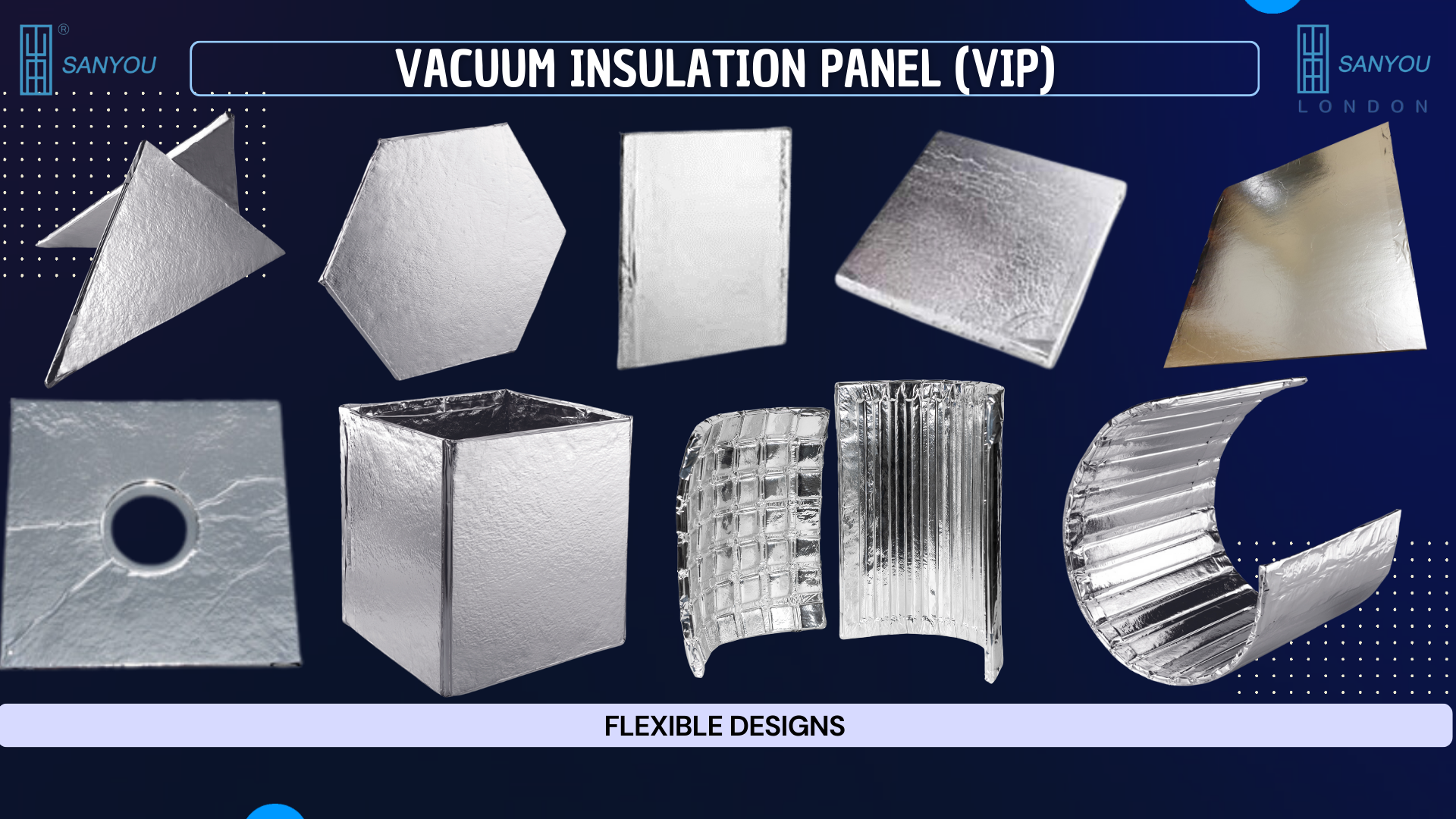

Reshape Your Project with our World-Class Vacuum Insulation Panel (VIP) offering Flexible Designs for High-Performance Vacuum Insulation, Energy Savings,

Noise Reduction, and Fire Safety

Idea for Energy-Efficient Construction in Diverse Climates

Video Demonstration: Vacuum Insulation Panel with Flexible Designs (VIP)

[English, Chinese, Arabic, Russian, German, Italian, French and Spanish]

Product Description

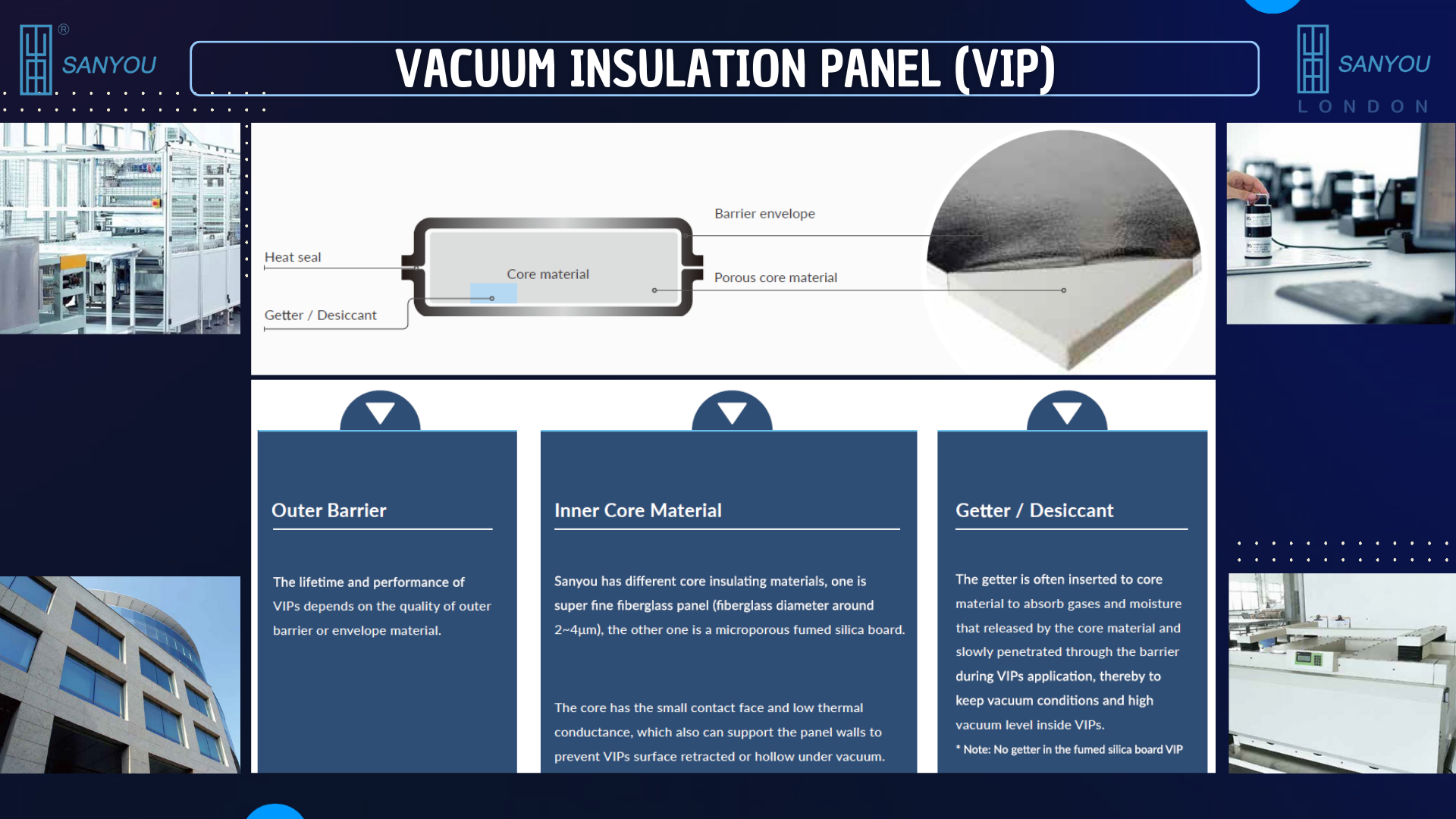

Ü Vacuum insulation panels (VIPs) play a crucial role in a range of applications, as detailed below, but primarily applied within the buildings and construction sectors that significantly enhance thermal insulation performance compared to traditional insulation materials. These panels consist of a core material (either super-fine fiberglass with getter/desiccant or microporous fumed silica) enclosed in a gas-tight envelope, creating a vacuum pressure of ≤ 1 Pa that greatly reduces heat transfer through conduction and convection. The importance of VIPs in the construction industry lies in their ability to improve energy efficiency, reduce carbon emissions, and enhance comfort within buildings.

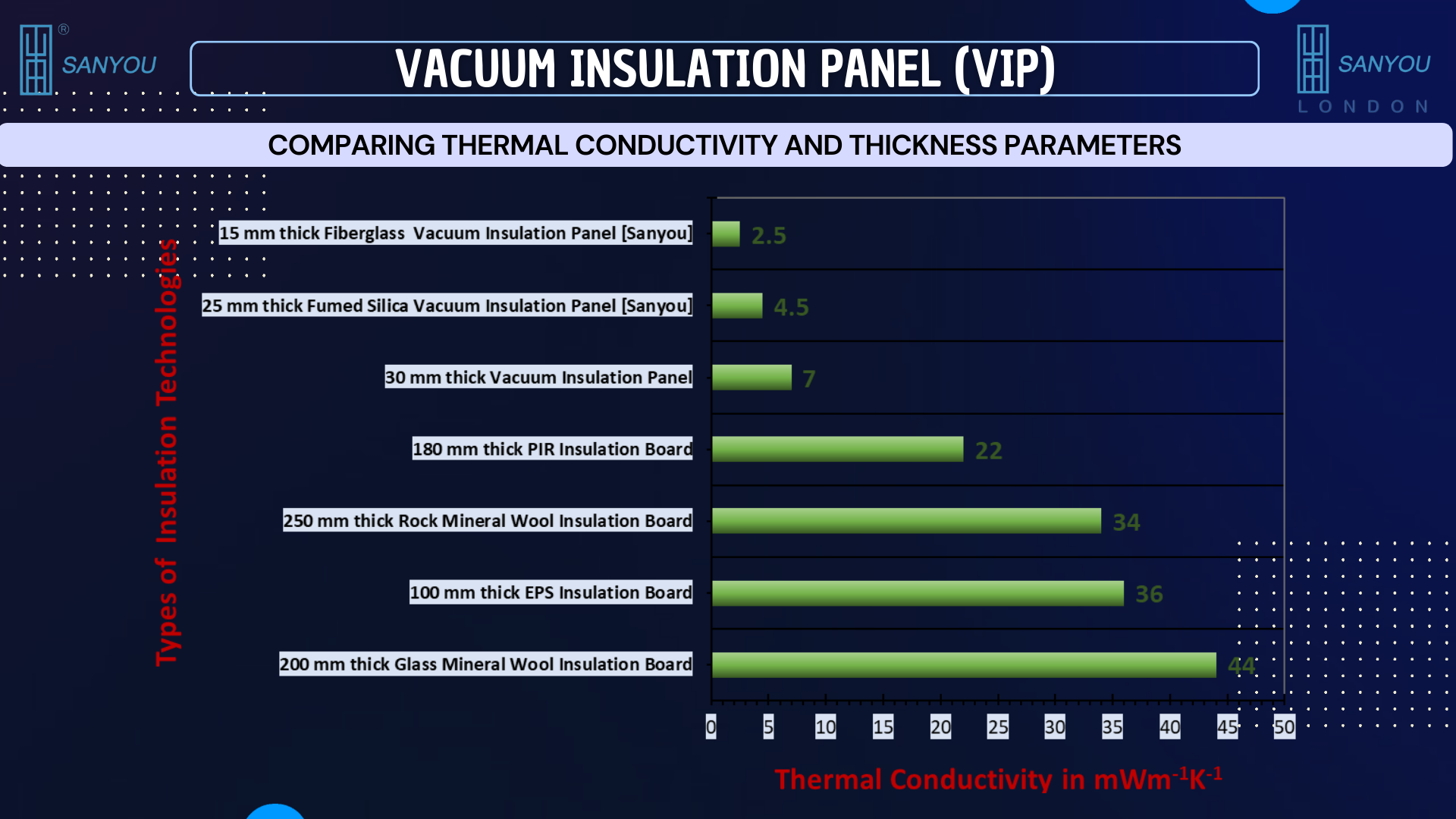

Ü In cold-arid regions, where heating is a primary concern, VIPs help minimize heat loss by providing superior insulation. Traditional insulation materials like XPS, EPS, mineral wool or polyurethane may be thicker and less efficient, requiring more space and materials to achieve the same level of insulation. VIPs, on the other hand, boast extremely low thermal conductivity, with 15 mm thick fiberglass VIPs having a thermal conductivity of ≤ 2.5 mW/(mK) and 25 mm thick fumed silica VIPs having a thermal conductivity of ≤ 4.5 mW/(mK), allowing for thinner insulation layers while maintaining high insulation performance. This saves space in construction and reduces the overall energy consumption needed to keep buildings warm. By minimizing heat loss, VIPs contribute to lower energy demand, thereby reducing carbon emissions associated with heating systems powered by fossil fuels.

Ü Similarly, in hot-arid regions where cooling is a significant energy demand, VIPs help to minimize cooling loss by preventing the transfer of heat from outside to the interior of buildings. Air conditioning systems often work overtime in hot climates to maintain comfortable indoor temperatures, leading to high energy consumption and increased carbon emissions. By incorporating VIPs into building envelopes, the need for cooling is reduced as the panels effectively block heat transfer, keeping interiors cooler for longer periods. This results in lower energy consumption for cooling, thereby mitigating carbon emissions associated with the operation of air conditioning systems powered by fossil fuels.

Ü Hence, the use of vacuum insulation panels in building construction offers a sustainable solution for minimizing carbon emissions caused by heat loss in cold-arid regions and cooling loss in hot-arid regions. By improving energy efficiency and reducing the reliance on heating and cooling systems, VIPs contribute to a more environmentally friendly built environment while also enhancing comfort and reducing operating costs for building occupants.

Key Characteristics

Ü Thermal Conductivity: VIPs exhibit extremely low thermal conductivity, with values typically below 2.5 mW/(mK) for materials like fiberglass and below 4.5 mW/(mK) for materials like fumed silica.

Ü Fire Rating: VIPs are typically non-combustible and have high fire rating of A, ensuring enhanced fire safety in construction applications.

Ü High Insulation Performance with Less Weight: Vacuum insulation panels (VIPs) offer superior insulation performance while being lightweight. By effectively obstructing heat conduction and convection radiation, VIPs minimize heat transfer through building envelopes, refrigeration units, and other applications. Their high insulation efficiency allows for thinner insulation layers compared to traditional materials, resulting in space-saving advantages without compromising performance.

Ü Reduced Energy Consumption and Carbon Emissions: VIPs contribute to reducing energy consumption and carbon emissions across various applications such as refrigerators, cold chain transportation, and construction. Their exceptional thermal insulation properties help minimize the need for heating and cooling, leading to decreased energy usage and environmental impact. Additionally, the space-saving advantages of VIPs optimize internal space utilization, enhancing overall efficiency.

Ü Comparative Analysis of Insulating Materials: Fiberglass, mineral wool, expanded polystyrene (EPS), polyurethane, and VIPs are compared based on their insulation thickness requirements. VIPs typically outperform traditional insulation materials in terms of thermal conductivity, allowing for thinner insulation layers while achieving the same or better insulation performance. This comparison highlights the superior efficiency and space-saving benefits of VIPs.

Ü Fiberglass VIP vs. Fumed Silica VIP: A comparison is made between fiberglass VIPs and fumed silica VIPs, two types of VIPs with different core materials. Both types offer exceptional thermal insulation performance, but they may vary in terms of specific properties such as thermal conductivity, weight, and cost. Evaluating the characteristics and benefits of each type allows for informed decisions regarding their suitability for different applications and insulation needs.

Ü Cost-effectiveness: While VIPs may have higher upfront costs compared to traditional insulation materials, their long-term energy savings and environmental benefits often outweigh the initial investment, making them cost-effective solutions in the construction industry.

Key Highlights

Ü Exceptional Thermal Performance: Vacuum insulation panels (VIPs) exhibit extremely low thermal conductivity, typically below 2.5 mW/m.K for materials like fiberglass and below 4.5 mW/m.K for materials like fumed silica. This outstanding thermal performance ensures superior insulation efficiency, effectively minimizing heat transfer and optimizing energy conservation in various applications.

Ü Enhanced Fire Safety and Lightweight Design: VIPs are typically non-combustible and have a high fire rating of A, ensuring enhanced fire safety in construction applications. Additionally, their lightweight design allows for easy installation and handling while offering high insulation performance. This combination of fire safety and lightweight construction makes VIPs a versatile and reliable choice for sustainable building practices.

Ü Cost-Effective Energy Efficiency: Despite potential higher upfront costs, VIPs offer long-term cost-effectiveness due to their reduced energy consumption and carbon emissions. By minimizing the need for heating and/or cooling, VIPs contribute to decreased energy usage and environmental impact, ultimately resulting in significant savings over time. Furthermore, their superior efficiency and space-saving benefits make VIPs a wise investment for optimizing building performance and achieving sustainability goals.

Comparison

Specifications

Colour | Silver

| |

Geometry | Rectangular and shapes, geometries, and sizes

| |

Operating Temperature | -40℃~+100℃

| |

Density | Fiberglass VIP

Fumed Silica VIP | 250~280 kg/m³

200~230 kg/m³

|

Thermal Conductivity | Fiberglass VIP [15 mm thick at mean temperature of 25°C]

Fumed Silica VIP [25 mm thick at mean temperature of 25°C]

| ≤ 0.0025 W/(m·k)

≤ 0.0045 W/(m·k) |

Thermal Resistance | Fiberglass VIP [15 mm thick at mean temperature of 25°C]

Fumed Silica VIP [25 mm thick at mean temperature of 25°C] | ≥ 6 m²·K/W

≥ 5.56 m²·K/W

|

Vacuum Pressure

| Internal Pressure | ≤ 1 Pa |

Getter / Desiccant | Fiberglass VIP

Fumed Silica VIP

| Yes

No

|

Maximum Dimensions [Length x Width] | Fiberglass VIP

Fumed Silica VIP

| 2000 mm x 1800 mm

1000 mm x 500 mm

|

Minimum Dimensions [Length x Width] | Fiberglass VIP

Fumed Silica VIP

| 250 mm x 250 mm

250 mm x 250 mm

|

Available Thicknesses | Fiberglass VIP

Fumed Silica VIP | 3 mm ~ 30 mm

5 mm ~ 40 mm

|

Manufacture Tolerances

Size Tolerances |

250 mm ~ 500 mm 501 mm ~ 1000 mm 1001 mm ~ 2000 mm Thickness tolerance

|

-4 mm ~ +2 mm -5 mm ~ +2 mm -6 mm ~ +3 mm -1.5 mm ~ +1.5 mm |

Flexible VIP Product Designs

Versatility in Shape, Geometry, and Size: Flexible VIPs can be tailored to fit various shapes, geometries, and sizes, making them suitable for diverse applications. This flexibility allows for seamless integration into different structures, systems, and components, enhancing their functionality and efficiency.

Applications

Ü Electric Vehicles (EVs) Applications

l Internal Insulation: Flexible VIPs can be used for internal insulation in electric vehicles, providing efficient thermal insulation to maintain comfortable cabin temperatures while reducing the energy demand on heating and cooling systems.

l Battery Compartment Thermal Management: Flexible VIPs can also be employed for thermal management in the battery compartment of EVs, ensuring optimal operating temperatures for battery performance and longevity.

Ü Transportation Industry Applications

l Large Trucks and Vehicles: Flexible VIPs can be installed in large trucks and vehicles to enhance thermal insulation and energy efficiency, reducing fuel consumption and greenhouse gas emissions.

l Cargo Containers: Flexible VIPs can be utilized in cargo containers to maintain desired temperatures during transportation, preserving the quality of perishable goods and reducing energy consumption.

Ü Construction Sector Applications

l Building Envelopes: Flexible VIPs can be integrated into building envelopes for superior thermal insulation in both residential and commercial structures, minimizing heat loss and reducing heating and cooling costs.

l Retrofitting Projects: Flexible VIPs offer versatility in retrofitting existing buildings, allowing for efficient insulation upgrades without significant alterations to the building structure.

Ü Refrigerator Applications

l VIPs can significantly improve the energy efficiency of refrigerators by providing superior insulation properties. By reducing heat transfer through the refrigerator walls, VIPs minimize the workload of the compressor, resulting in energy savings and increased internal space for storage. Their advanced thermal insulation capabilities offer multiple advantages over traditional materials, including enhanced energy efficiency and internal space optimization.

Ü Electronics and Automation Applications

l Electronic Enclosures: Flexible VIPs can be used in electronic enclosures to manage heat dissipation and maintain optimal operating temperatures for electronic components, ensuring reliability and longevity.

l Industrial Automation Systems: Flexible VIPs can contribute to energy efficiency and thermal management in industrial automation systems, improving overall system performance and reducing operational costs.

Ü Medical and Pharmaceutical Storage

l Cold Storage Units: Flexible VIPs can be utilized in cold storage units for medical and pharmaceutical storage, maintaining precise temperature control to preserve the integrity of temperature-sensitive products.

Video

FAQs

FAQs about Vacuum Insulation Panel (VIP) with Flexible Design Options

What are Vacuum Insulation Panels (VIPs) and how do they work?

VIPs are advanced insulation materials that consist of a core material (like super-fine fiberglass or microporous fumed silica) enclosed in a gas-tight envelope, under a vacuum pressure of ≤ 1 Pa. This vacuum significantly reduces heat transfer through conduction and convection, offering superior insulation performance. Think of it like an incredibly efficient thermal flask that keeps your drink hot or cold by preventing heat from getting in or out.

Why are VIPs considered better than traditional insulation materials?

VIPs have extremely low thermal conductivity, making them much more efficient than traditional materials like XPS or mineral wool. For example, a 15 mm thick fiberglass VIP has a thermal conductivity of ≤ 2.5 mW/(mK), allowing for thinner layers with higher insulation performance. This means buildings can be insulated more effectively without losing valuable space, ultimately reducing energy consumption and carbon emissions.

How do VIPs contribute to energy efficiency in buildings?

In both cold and hot climates, VIPs minimize heat loss or gain, reducing the need for heating or cooling. This lowers energy consumption and, consequently, carbon emissions from fossil fuel-powered systems. It's like wearing a high-performance thermal jacket; you stay comfortable inside without having to constantly adjust the heating or cooling, leading to significant energy savings.

Can VIPs be used in any type of construction or retrofitting project?

Absolutely! VIPs are versatile and can be adapted to various shapes, sizes, and geometries, making them suitable for new constructions as well as retrofitting existing buildings. Whether you're designing a modern home or upgrading an old office building, VIPs can be tailored to meet specific insulation needs without compromising on space or aesthetics.

Are there different types of VIPs for different applications?

Yes, VIPs come in two main types: fiberglass with getter/desiccant and fumed silica. Each has its unique properties, like thermal conductivity and weight, making them suitable for different applications. For instance, fiberglass VIPs might be preferred for lightweight needs, while fumed silica VIPs could be chosen for their slightly better insulation performance.

Is it true that VIPs have a high fire rating?

Indeed, VIPs typically have a high fire rating of A, meaning they're non-combustible and enhance fire safety in construction applications. This adds an extra layer of security to buildings, much like a fire-resistant safe protects valuable documents in a fire.

Considering their benefits, are VIPs cost-effective?

While the initial investment in VIPs might be higher than traditional materials, the long-term energy savings and environmental benefits they offer make them a cost-effective solution. Think of it as investing in a high-quality appliance that uses less electricity; the upfront cost is higher, but the energy savings over time make it worth it.

How do VIPs impact the overall design and aesthetics of buildings?

Thanks to their thin profile and flexibility in shape and size, VIPs can be seamlessly integrated into building designs without compromising aesthetics or internal space. This allows architects and designers to maintain their vision while achieving high insulation performance, akin to integrating high-tech features into a sleek smartphone design.

Can VIPs be used in applications outside of construction?

Yes, VIPs are also used in electric vehicles, transportation (like in cargo containers), refrigeration (enhancing efficiency in refrigerators), electronics, and even medical and pharmaceutical storage, thanks to their excellent thermal insulation properties.

What are the core materials used in Sanyou's VIPs?

Sanyou's VIPs are made with two types of core materials: super-fine fiberglass and fumed silica. Fiberglass VIPs incorporate a getter/desiccant to maintain the vacuum, whereas fumed silica VIPs do not have a getter/desiccant.

What are the thermal conductivity values for Sanyou's VIPs?

The thermal conductivity for Sanyou's VIPs is impressively low, ensuring superior insulation performance. For fiberglass VIPs (15 mm thick), the thermal conductivity is ≤ 0.0025 W/(mk), and for fumed silica VIPs (25 mm thick), it is ≤ 0.0045 W/(mk).

How do Sanyou's VIPs compare to traditional insulation materials in terms of thermal conductivity?

Sanyou's VIPs outperform traditional insulation materials significantly. For context, glass mineral wool has a thermal conductivity of 44 mW/(mk), EPS is 36 mW/(mk), rock mineral wool is 34 mW/(mk), and PIR is 22 mW/(mk). Sanyou's fiberglass VIP stands at 2.5 mW/(mk), and fumed silica VIP at 4.5 mW/(mk), showcasing their superior efficiency.

What sizes and thicknesses are available for Sanyou's VIPs?

Sanyou offers a wide range of sizes, with maximum dimensions up to 2000 mm x 1800 mm for fiberglass VIPs and 1000 mm x 500 mm for fumed silica VIPs. The available thicknesses range from 3 mm to 30 mm for fiberglass VIPs and from 5 mm to 40 mm for fumed silica VIPs.

Can Sanyou's VIPs be used in extreme temperatures?

Absolutely. Sanyou's VIPs are designed to operate effectively in a wide temperature range, from -40℃ to +100℃, making them suitable for various applications from cold storage to high-temperature environments.

What is the vacuum pressure inside Sanyou's VIPs?

The vacuum pressure inside Sanyou's VIPs is maintained at ≤ 1 Pa, which is crucial for their high insulation performance by minimizing heat transfer through air conduction and convection.

Are there any manufacture tolerances in the dimensions of Sanyou's VIPs?

Yes, there are manufacture tolerances to ensure precision in production. For lengths between 250 mm to 500 mm, the tolerance is -4 mm to +2 mm, and it adjusts slightly as the dimensions increase, ensuring that the VIPs fit perfectly in their designated applications.

Why choose Sanyou's VIPs over traditional insulation materials?

Choosing Sanyou's VIPs means opting for cutting-edge insulation technology that offers unparalleled thermal efficiency, space-saving design due to their thin profile, and versatility in application due to their operational temperature range and size variability. Despite their higher initial cost, their long-term energy savings and reduced carbon footprint make them a sustainable and cost-effective choice.

How can I learn more or get a quote for my project?

For more information or to discuss your specific project needs, including price quotations and tailored VIP solutions, feel free to contact our Customer Services Team at info@sanyoulondon.com or call us at +44 204 570 5354. We're here to help you elevate your project with innovative insulation solutions that meet your dimensional and aesthetic requirements.