Overview

Empowering Sustainable Energy Saving Solutions

Innovations in Vacuum Insulation Energy Technologies

Discover how our cutting-edge research and manufacturing facilities are driving advancements in vacuum insulation energy technologies, shaping a sustainable future through innovative energy saving solutions and collaborative partnership

Key Highlights

Ü Mass Manufacturing Facility: Equipped with advanced technology, our facility ensures high-quality vacuum insulation solutions with a focus on innovation and efficiency.

Ü Industry Standard Measurement and Validation: Precise thermal conductivity measurement and comprehensive inspection processes guarantee the integrity of our products.

Ü Specialized Experimental Research Laboratory: Our state-of-the-art lab conducts in-depth analysis of electrical and thermal performance, utilizing advanced measurement tools and techniques.

Ü Onsite Real-Time Performance Houses: Witness groundbreaking experiments in dynamic energy, thermal, and sound insulation performance analysis, driven by cutting-edge data collection and analysis.

Ü Intellectual Property Patents Protection: We uphold our commitment to innovation and quality with patented technologies and a dedicated R&D team.

Ü Consultancy and Collaboration: Partner with us to implement sustainable vacuum insulation energy technologies and drive positive change globally.

Ü TRL 9 Industrial Research: Explore transformative innovations, from concept to tangible products, exemplifying our dedication to sustainable development goals.

Ü Inspiring Solutions for a Sustainable Future: Our research not only addresses SDGs but also inspires new solutions, paving the way for a more sustainable tomorrow.

Ü Mass Manufacturing Facility for Vacuum Insulation Energy Technologies

l Cutting-Edge Manufacturing Facility: Equipped with state-of-the-art Vacuum Insulation Panel (VIP) machines imported from Germany, our facility boasts the largest evacuation chamber, featuring maximum effective dimensions of 3800 x 1850 x 50 mm.

l High Production Capacity: With an estimated annual output of approximately 2,500,000 square meters, our manufacturing capabilities ensure a steady and substantial supply of vacuum insulation technologies to meet diverse market demands.

l Quality Assurance Through Intellectual Property: Our facility employs cutting-edge, IP-protected processes to uphold the highest standards of vacuum insulation quality. Automated sealing mechanisms further enhance efficiency and precision in production.

l Industry-Leading Innovation: Committed to continuous improvement and innovation, we strive to maintain our position at the forefront of vacuum insulation energy technologies, delivering superior products and solutions to the world.

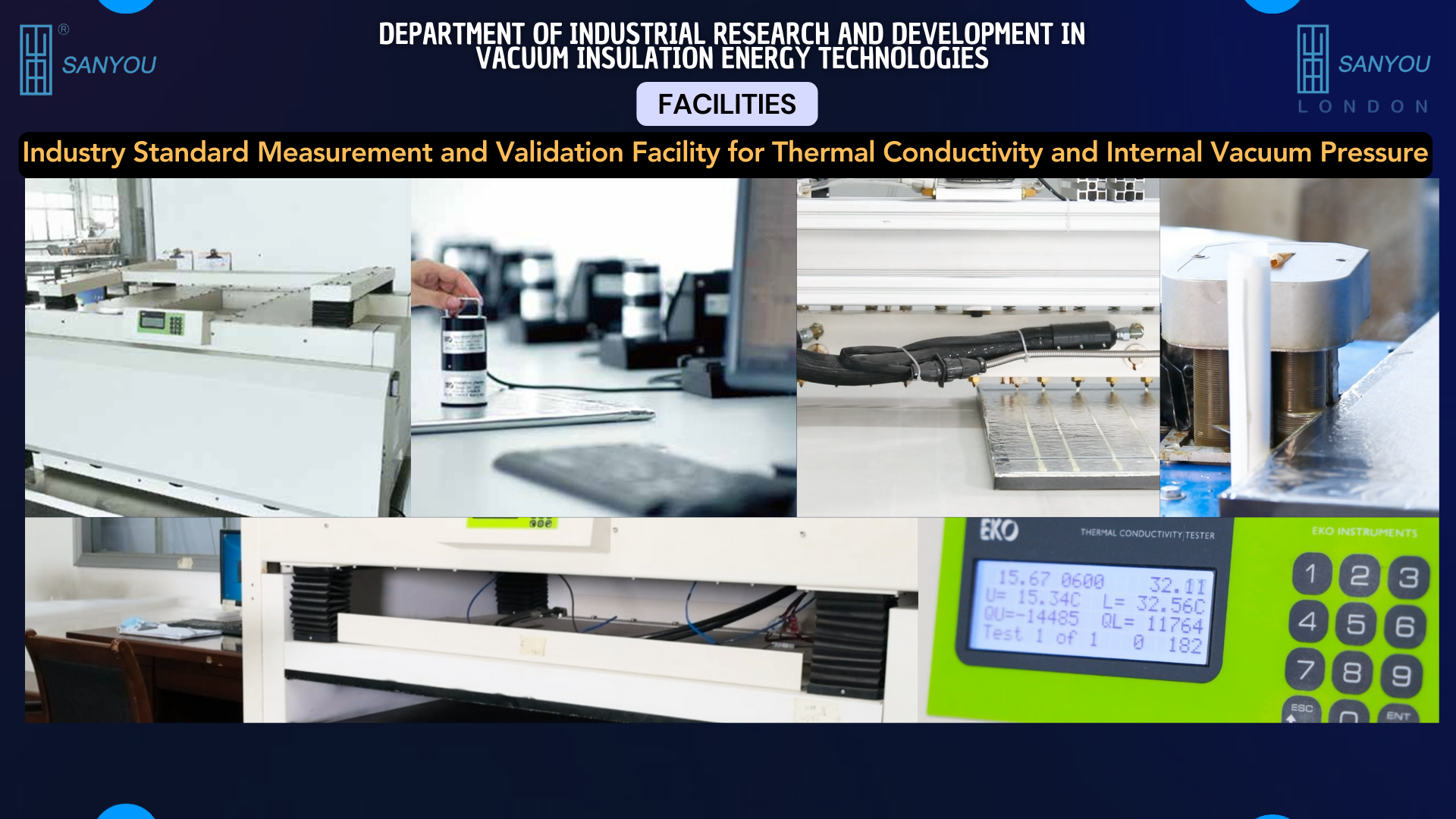

Ü Industry Standard Measurement and Validation Facility for Thermal Conductivity and Internal Vacuum Pressure

l Cutting-Edge Measurement and Validation Facility: Our facility is equipped with industry-standard tools for precise measurement and validation of thermal conductivity, including a laser comp thermal conductivity tester.

l Comprehensive Inspection Process: Prior to delivery, all Vacuum Insulation Panels (VIPs) undergo thorough inspection, ensuring quality and performance. With the capability to inspect VIPs of various designs, our facility accommodates effective sizes up to 350 mm in width and unlimited lengths.

l Innovative Internal Vacuum Pressure Measurement: Utilizing our patented technique, we conduct rapid and accurate measurements of internal vacuum pressure, ensuring the integrity and efficiency of our vacuum insulation products.

l Commitment to Quality Assurance: At our facility, we prioritize quality assurance throughout the manufacturing process, employing advanced technologies and techniques to deliver superior vacuum insulation solutions to our discerning clientele.

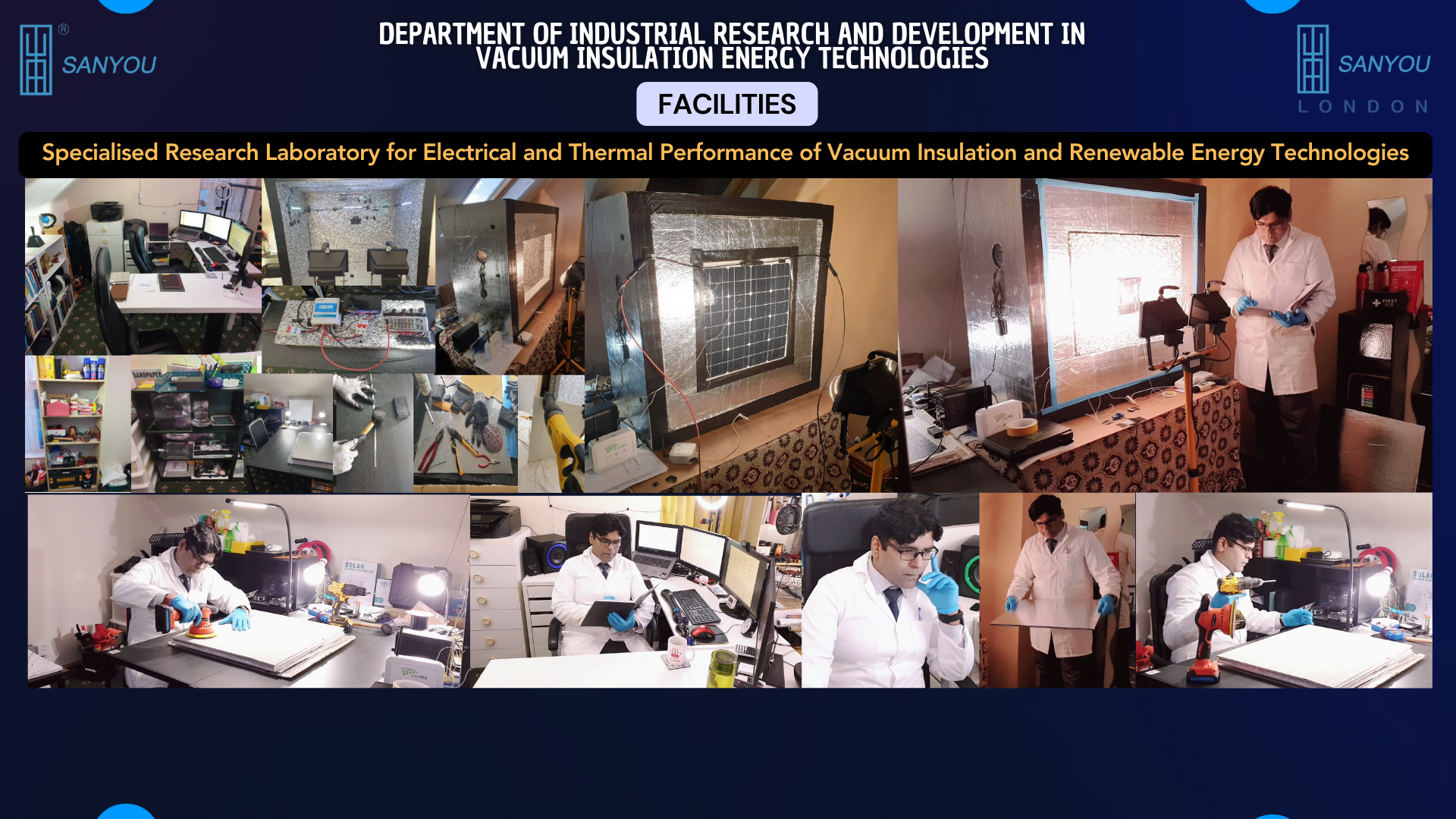

Ü Specialised Research Laboratory for Electrical and Thermal Performance of Vacuum Insulation and Renewable Energy Technologies

l Specialised Experimental Research Facility: Our laboratory specializes in conducting comprehensive research on the electrical and thermal performance of vacuum insulation and renewable energy technologies.

l Industry-Standard U Value Measurements: Equipped with ISO 9869-1:2014-certified instrumentation, we ensure precise U value measurements, adhering to international standards for accuracy and reliability.

l Versatile Temperature Control Capabilities: Utilizing a specialized temperature-controlled hot-box calorimeter, our laboratory assesses performance across diverse climatic conditions, catering to both cold and hot arid climates.

l Advanced Measurement and Analysis Tools: From dynamic temperature measurement facilities to solar charge controllers and electrical power measurement capabilities, our laboratory boasts a range of cutting-edge equipment, including remote temperature sensors, sound measurement devices, electronic circuit board soldering facilities, and an array of tools for sample design and craftsmanship, empowering us to conduct thorough and precise experimentation for groundbreaking insights and innovations in the field.

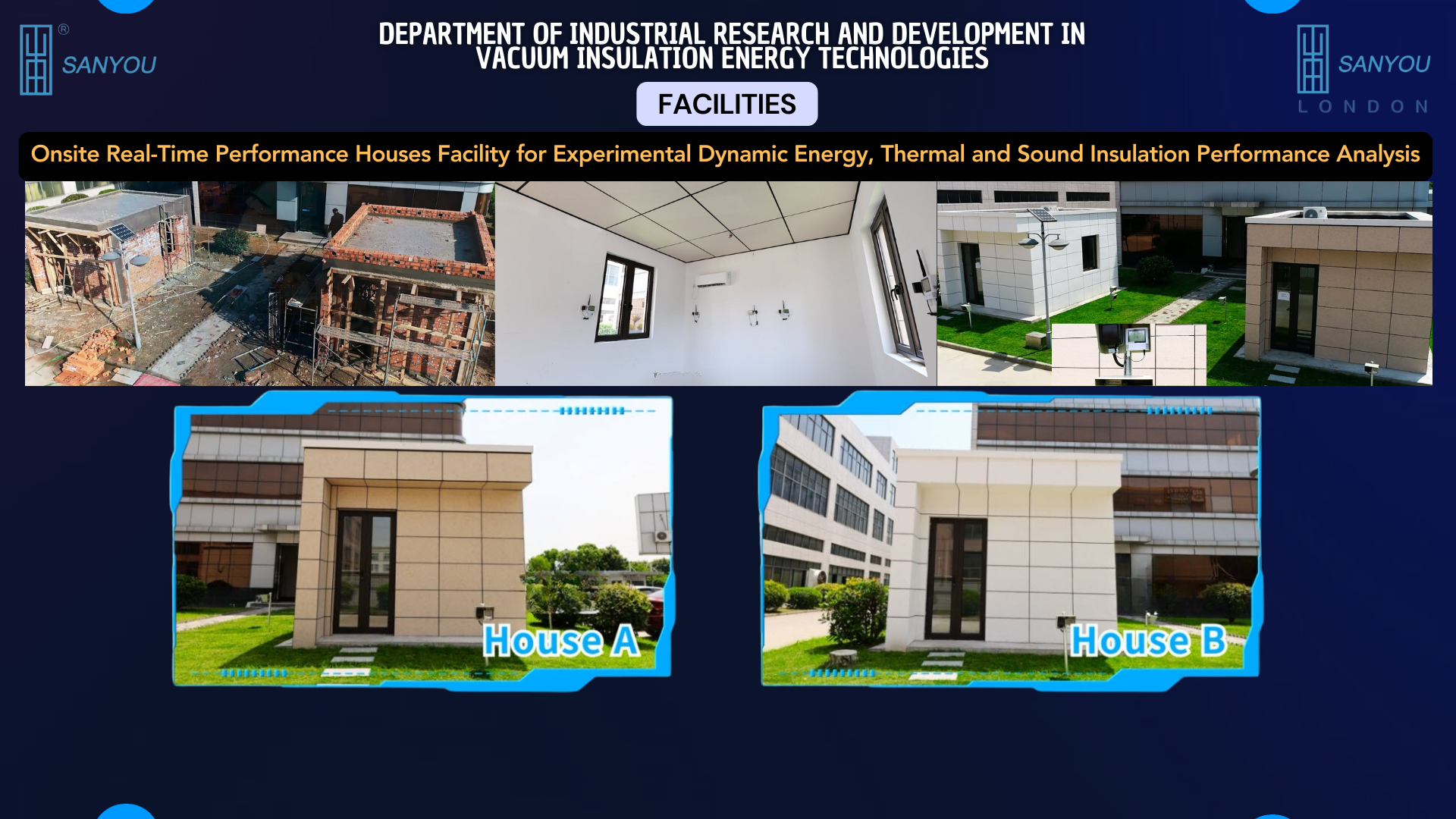

Ü Onsite Real-Time Performance Houses Facility for Experimental Dynamic Energy, Thermal and Sound Insulation Performance Analysis

l Innovative Real-Time Experimental Housing: Our onsite experimental facility features two identical houses (House A and House B) constructed to facilitate groundbreaking research into energy consumption, sound insulation, and thermal performance in dynamic cold arid and hot arid environments.

l Diverse Construction Materials: House A showcases decorative integrated Vacuum Insulation Panel (VIP) tiles, while House B utilizes homogeneous panels of equivalent thickness. This allows for comparative analysis of performance between different construction materials.

l Comprehensive Experimental Protocols: Our state-of-the-art facility conducts a series of experiments to assess energy consumption, rewarming efficiency, and sound insulation. This includes analysing air conditioning usage and power consumption, testing rewarming efficiency at controlled temperatures, and real-time sound insulation measurements using advanced sound detection equipment.

l Cutting-Edge Performance Data Collection and Analysis: Leveraging advanced instrumentation, our facility captures real-time data on energy usage, temperature fluctuations, and sound insulation effectiveness. This data is accurately analysed to drive insights and innovations in building design and construction practices.

Ü Intellectual Property Patents Protection

l Intellectual Property: Our Vacuum Insulation Energy Technologies such as our products for sales are patented and is the intellectual property of Sanyou with our certification of ISO9001. We have professional R&D team focused on Material Science, Polymer Physics, Mechanical and Electrical Automation, ANSYS simulation and various onsite experimental facilities. SANYOU owns 90+ national and international patents covering manufacturing process, machinery and products.

l Patented Vacuum Insulation Energy Technologies: Our patented products, representing the intellectual property of Sanyou, are crafted with precision and innovation to meet the highest standards in energy efficiency. Certified with ISO9001 accreditation, our commitment to quality is significant.

l Expert R&D Team: Our dedicated team of professionals specializes in diverse fields including Material Science, Polymer Physics, Mechanical and Electrical Automation, and ANSYS simulation. This multidisciplinary approach ensures comprehensive research and development, leading to continuous improvement and innovation.

l Extensive Patent Portfolio: With over 90 national and international patents, Sanyou is a leader in innovation within the industry. Our patents cover a wide range of aspects including manufacturing processes, machinery, and product designs, solidifying our position at the forefront of technological advancement.

l State-of-the-Art Experimental Facilities: Equipped with advanced onsite experimental facilities, we conduct rigorous testing and validation to ensure the performance and reliability of our products. These facilities enable us to push the boundaries of innovation and deliver cutting-edge solutions to our clients worldwide.

Ü Consultancy and Collaboration in Implementing Vacuum Insulation Energy Technologies

l Global Consultancy and Collaboration Initiative: We are committed to fostering partnerships and consultancy opportunities worldwide to facilitate the practical implementation of our vacuum insulation energy technologies. By collaborating with industry leaders and stakeholders, we aim to drive widespread adoption and maximize the impact of our innovative solutions.

l Pioneering Net-Zero Energy Buildings: With a strategic focus on the building and construction sector, we are at the forefront of enabling the realization of net-zero energy buildings. Our vacuum insulation products and technologies play a pivotal role in this endeavour, offering sustainable solutions that significantly reduce electricity and gas consumption, thereby minimizing environmental impact while maximizing energy efficiency.

l Empowering Individuals and Communities: Our vacuum insulation technologies are designed not only to enhance energy efficiency but also to empower individuals and communities worldwide. By minimizing electricity and gas bills, our solutions alleviate financial burdens, improve quality of life, and contribute to sustainable development goals on a global scale.

l Promoting Sustainable Development: Through our collaborative efforts and consultancy services, we seek to promote sustainable development practices across borders. By leveraging the transformative potential of vacuum insulation technologies, we are driving positive change, creating resilient communities, and building a more sustainable future for generations to come.

Ü Realizing TRL 9 Industrial Research into Innovative Products

l Explore a spectrum of groundbreaking advancements from innovative idea to TRL 9 applied industrial research translated into tangible and innovative products. A few examples are:

R Vacuum Insulated Wallpaper (VIW)

R Decorative Integrated Vacuum Insulation Panel

R Flexible Design Vacuum Insulation Panel (VIP)

R Vacuum Insulated Bag-or-Box (Medical Box, Deep Cold Box, Rolling Cart Cover and Fresh Bag)

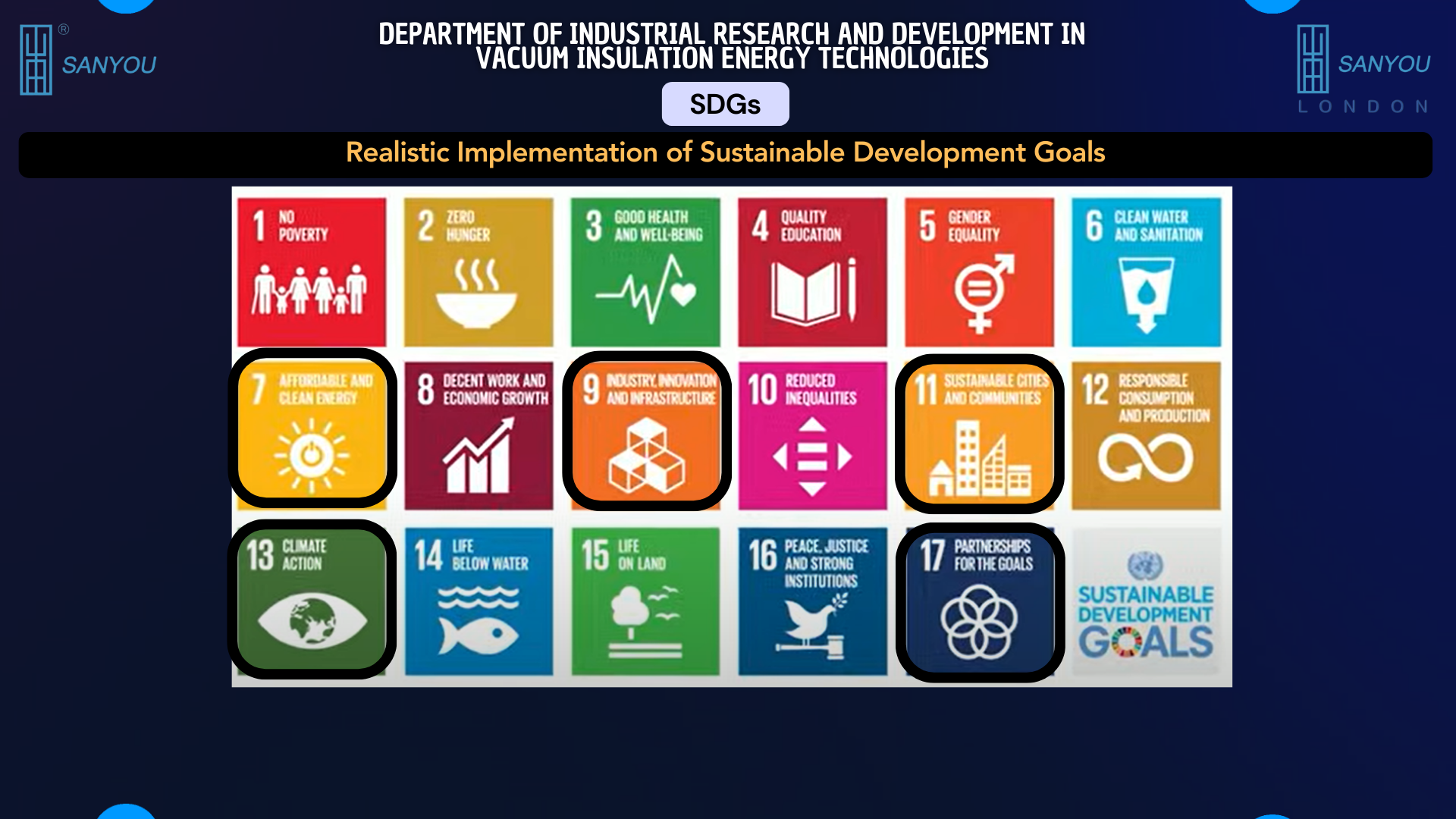

Ü Realistic Implementation of Sustainable Development Goals

l Our research not only explores the realistic and direct implementation of Sustainable Development Goals (SDGs), such as affordable and clean energy, industry, innovation and infrastructure, sustainable cities and communities, climate action, and partnerships for the goals, but also serves as an inspiration for new solutions, as demonstrated by the extensive case studies highlighted earlier.

Videos

Video Demonstration: Our Mass Manufacturing and Production Achievements in Vacuum Insulation Energy Saving Technologies

[English, Chinese, Arabic, Russian, German, Italian, French and Spanish]