What makes our Vacuum Insulation Panel genuinely innovative—and smarter than conventional insulation?

Short answer: performance per millimetre. Thick layers of conventional materials can achieve good U-values—if you have the depth. Our VIPs reach those U-values in a fraction of the thickness, so you keep floor area, window proportions and clean detailing, while cutting heating and cooling demand.

First principles—what are we comparing?

- Thermal conductivity (λ): the material property. Lower is better.

- Thickness (d): more thickness usually means more resistance.

- U-value: heat flow per m² per degree. Lower is better. For a single layer, U≈λ/dU \approx \lambda / dU≈λ/d (films and fixings aside).

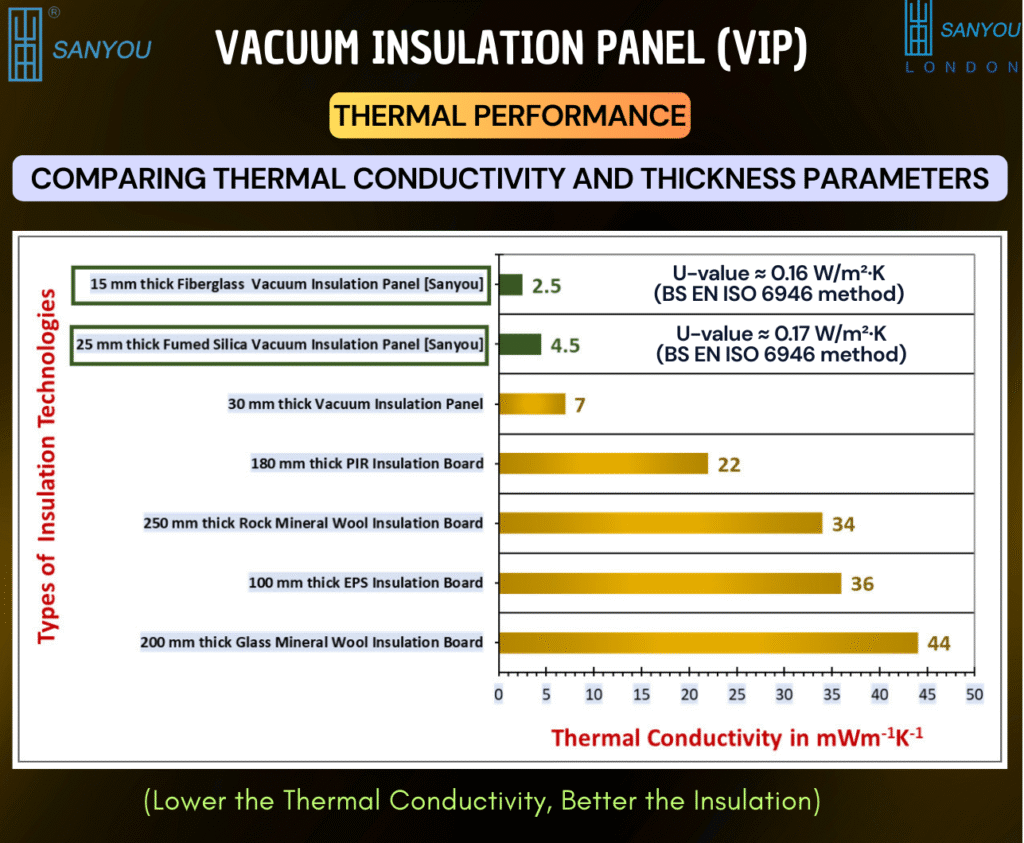

Our VIP performance (programme data)

- 15 mm super-fine fibreglass VIP: λ ≈ 2.5 mW·m⁻¹·K⁻¹, U ≈ 0.16 W·m⁻²·K⁻¹

- 25 mm fumed-silica VIP: λ ≈ 4.5 mW·m⁻¹·K⁻¹, U ≈ 0.17 W·m⁻²·K⁻¹

These are centre-of-panel values under steady conditions, achieved by combining a deep vacuum (typically <10 Pa), a microporous core, and low-emissivity barrier skins with getter/desiccant for long-term stability.

Conventional benchmarks (typical declared λ)

- Rock mineral wool (250 mm used as a reference thickness): λ ≈ 34 mW·m⁻¹·K⁻¹

- Glass mineral wool (200 mm reference): λ ≈ 44 mW·m⁻¹·K⁻¹

- PIR board (180 mm reference): λ ≈ 22 mW·m⁻¹·K⁻¹

- EPS (100 mm reference): λ ≈ 36 mW·m⁻¹·K⁻¹

Conductivity is a material property; thickness is what you need to turn that property into a target U-value. That’s where VIPs change the maths.

The fair comparison: “How thick to hit ~0.17–0.18 W·m⁻²·K⁻¹?”

(Illustrative one-layer calculation, ignoring fixings and surface films for clarity.)

| Insulation type | Declared λ (W·m⁻¹·K⁻¹) | Thickness to reach U ≈ 0.18 W·m⁻²·K⁻¹ |

|---|---|---|

| VIP (fibreglass core) | 0.0025 | ≈ 14 mm |

| VIP (fumed silica core) | 0.0045 | ≈ 25 mm |

| PIR board | 0.022 | ≈ 122 mm |

| Rock mineral wool | 0.034 | ≈ 189 mm |

| EPS | 0.036 | ≈ 200 mm |

| Glass mineral wool | 0.044 | ≈ 244 mm |

What this shows: to meet a demanding U-value, VIPs need centimetres, while conventional products often need decimetres. In real buildings that difference drives design, cost and comfort.

Why thin matters to designers, QS teams, and occupants

- Net internal area preserved. Swapping ~200 mm internal build-ups for ~15–25 mm can protect several square metres in a typical flat—value buyers understand instantly.

- Clean reveals and details. Slim profiles keep window proportions, avoid deep sills and soffits, and simplify junctions at stairs, lifts and risers.

- Fewer clashes. Services, radiators, cupboards and door swings stay where drawings intended; less rework on site.

- Programme certainty. Off-site made-to-size VIPs reduce cut-and-fit variability; faster dry trades, fewer wet works.

- Operational savings. Lower U-values reduce heat loss/gain, so HVAC runs softer with fewer hard restarts after short outages. Occupants feel steadier temperatures and lower bills.

“Best thermal performance”—said precisely

- Per millimetre, VIPs outperform foams and wools.

- In absolute terms, very thick conventional systems can match low U-values, but at the cost of space, weight, and detailing complexity.

- In space-constrained or heritage settings, VIPs are often the only practical route to high performance.

Not just numbers—how we make it durable

- Deep vacuum (<10 Pa): suppresses gas conduction and convection.

- Microporous cores: super-fine fibreglass or fumed silica to minimise solid conduction.

- Low-e barriers: reduce radiative transfer.

- Dual edge seals + getter/desiccant: manage permeation and outgassing to support an ageing life ≥ 25 years when protected as specified.

- Protection by design: cassettes/skins, no-penetration zones, and detailed returns keep the performance you paid for.

Where to use which VIP

- 15 mm fibreglass VIP (λ ≈ 2.5 mW·m⁻¹·K⁻¹): extremely tight internal linings, reveals, door leaves, cabinet and duct liners, heritage interiors where every millimetre counts.

- 25 mm fumed-silica VIP (λ ≈ 4.5 mW·m⁻¹·K⁻¹): slim façades, spandrels and panels where a little more depth is acceptable for robust handling.

For façades that must also be the finish, specify our Decorative Integrated Vacuum Panels (DVIP); for fast internal upgrades, see Vacuum Insulated Wallpaper (VIW); for window lines, Vacuum Insulated Curtain (VIC) or the low-power VIHC.

Frequently raised concerns—answered

“Can I cut it on site?”

No. VIPs are sealed vacuum elements. We supply made-to-size panels, including curves, tapers and service cut-outs.

“What about fire performance?”

Fire class is an assembly property. We provide configurations—including A-class façade options—to suit your strategy.

“What if a panel is damaged?”

Modules are protected in use and replaceable. We plan fixings and access so rare interventions are straightforward.

Ready to specify—and want a quick thickness/U-value sketch?

- Contact our Customer Service Team for samples, CAD details and tailored pricing.

- Prefer a direct conversation? Email or phone Professor Saim Memon to review drawings, performance targets and a room-by-room or façade plan.

- Explore full specifications, purchasing steps, videos and FAQs at www.sanyoulondon.com.

Bottom line: if you want top-tier thermal performance without giving up space, our VIPs deliver the U-values you need in the fewest millimetres possible—precise, durable, and ready for real buildings.

Share

Author

Prof. Dr. Saim Memon

PhD, CEng, FHEA, MSc, BEng(Hons), PGC-TQFE, GTCS, MCMI, MIET, MIEEE, MInstP, IBPSA, APCBEES, MPEC

CEO | Industrial Professor | Inventor | British Scientist | Chartered Engineer | Qualified Teacher | Chief Editor | World Speaker | Pioneer in Vacuum Insulation Energy Technologies