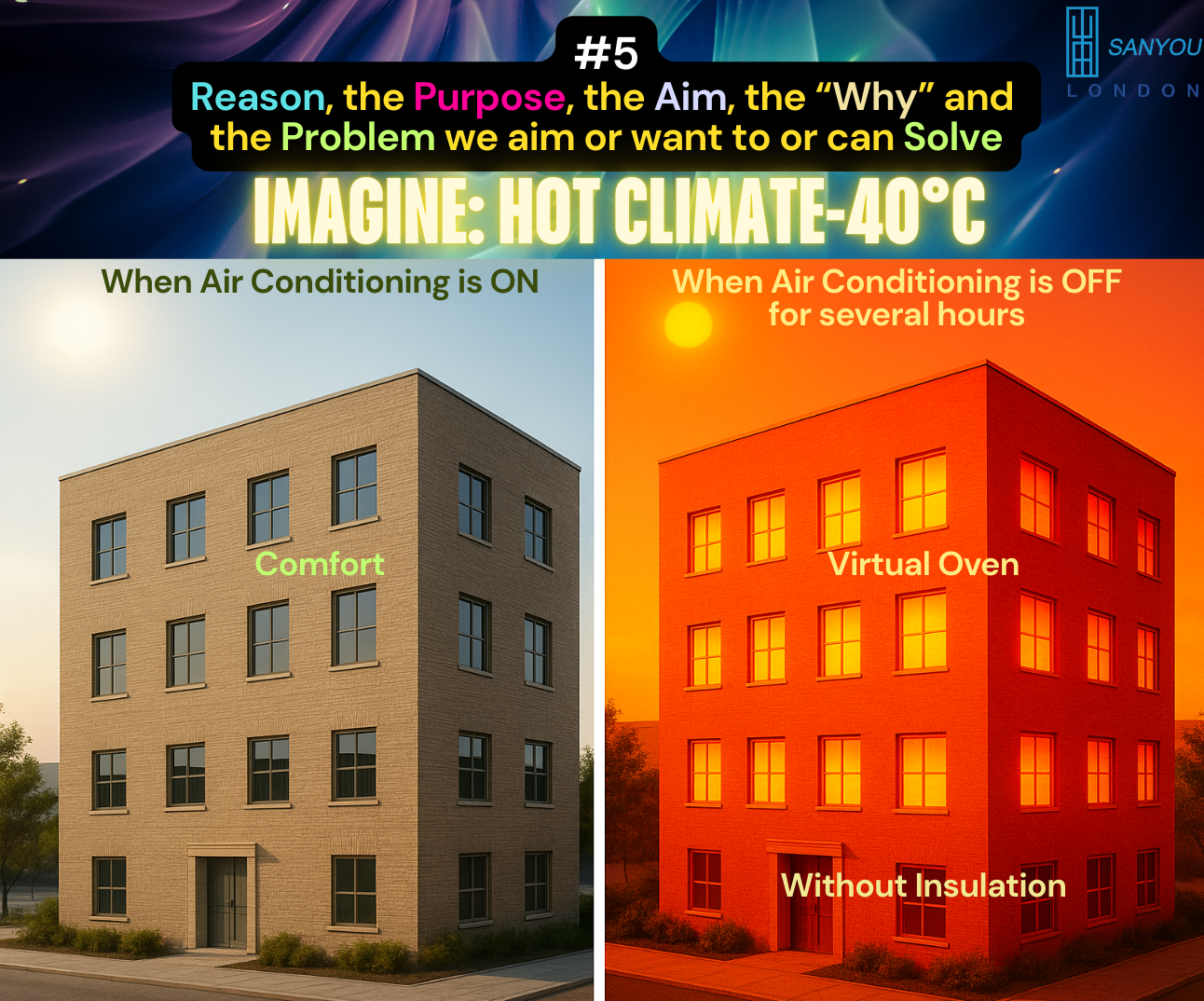

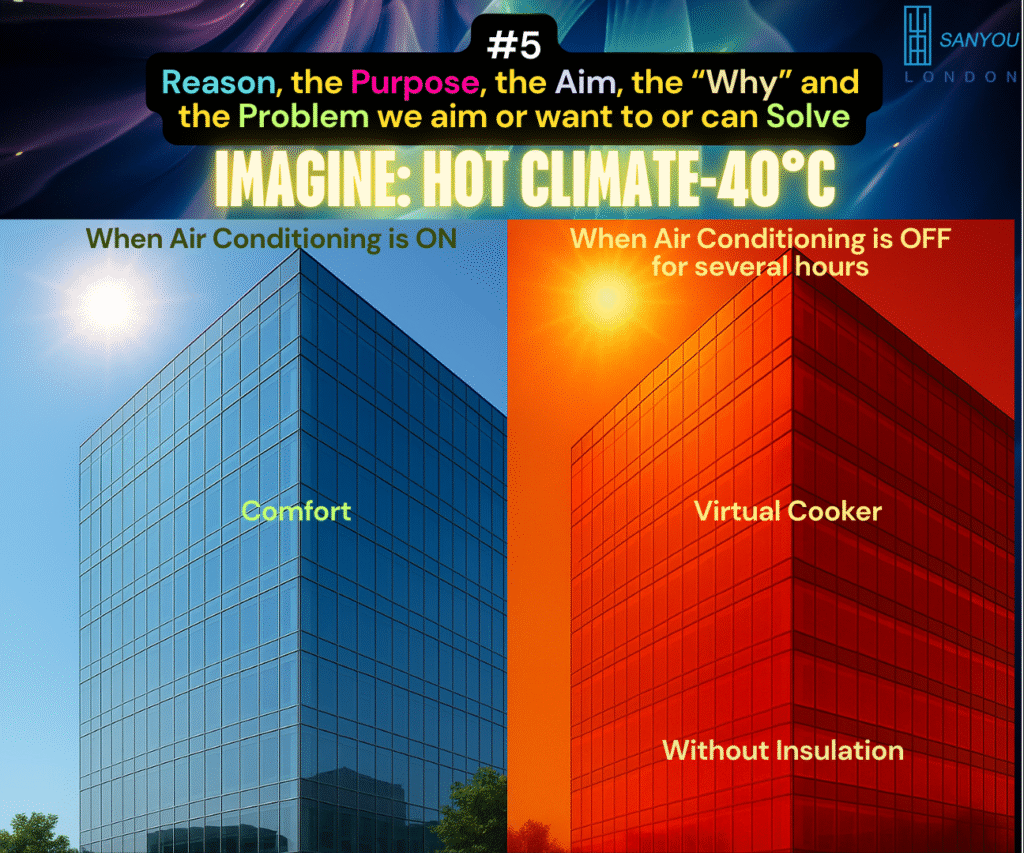

Imagine the AC stops at 40 °C: how fast does your building overheat—and what can you do about it?

Let’s make this practical. In a hot climate, a space feels fine while air conditioning runs. The moment chillers cut out—grid dip, plant fault, demand response, planned maintenance—the clock starts. Without insulation, especially behind a shiny glass façade, the room soaks up heat like an oven.

Below are realistic, back-of-envelope scenarios to help facility managers see the risk and choose effective mitigations.

Scenario A — mixed lobby, part glazed (illustrative)

Assumptions

- Lobby volume: 1,000 m³ (e.g., 300 m² floor × 3.3 m clear height)

- Glazing: 150 m², solar heat-gain coefficient (SHGC) 0.5

- Midday sun on glass: ≈700 W/m²

- Outside 40 °C; inside when AC stops 24 °C → ΔT = 16 K

- Glass U-value ≈5 W/m²K (older single/poor double)

- Infiltration: 0.5 ACH (doors, stack)

- Internal gains: people + lighting ≈3 kW

- “Active” thermal mass participating in the first hour: ≈50 t of structure and contents (only a fraction of the building mass responds quickly)

Heat coming in (order of magnitude)

- Solar through glass: 150 m² × 0.5 × 700 W/m² → ≈52.5 kW

- Conduction through glass: 150 m² × 5 × 16 → ≈12 kW

- Infiltration (0.5 ACH): ≈2.7 kW

- Internal: ≈3 kW

Total gain: ≈70 kW

Time to get uncomfortable

- Target rise to “warm and stuffy”: +6 K (24 → 30 °C)

- With ≈50 t active mass + room air, ≈62 minutes

- To +8 K (24 → 32 °C): ≈82 minutes

Takeaway: even a part-glazed lobby drifts out of comfort in about an hour when chillers stop on a 40 °C day.

Scenario B — fully glazed atrium or hotel lobby (illustrative)

Assumptions

- Volume: 2,000 m³

- All-glass façade: 400 m², SHGC 0.6

- Sun on glass: ≈800 W/m²

- U-value: ≈5 W/m²K; ΔT 16 K

- Infiltration: 0.5 ACH

- Internal gains: ≈5 kW

- Fast-responding mass (lots of glass, less heavy interior): ≈40 t

Heat coming in

- Solar: 400 × 0.6 × 800 → ≈192 kW

- Conduction: 400 × 5 × 16 → ≈32 kW

- Infiltration: ≈5 kW

- Internal: ≈5 kW

Total gain: ≈234 kW

Time to get uncomfortable

- To +6 K (24 → 30 °C): ≈15 minutes

- To +8 K (24 → 32 °C): ≈20 minutes

Takeaway: a glass box heats frighteningly fast. If chillers trip during a busy check-in, you have minutes, not hours, before guests feel it.

These are illustrative, not compliance calculations. Thermal mass participation varies; sun angles, shading, SHGC and airtightness matter. The point is the trend: glass + no insulation = rapid overheat.

Why facility managers should care (beyond guest comfort)

- Health and safety: overheating elevates heart rate and dehydration risk for vulnerable occupants; staff productivity drops.

- Brand risk: public complaints and reviews spike after visible lobby failures; recovery takes months.

- Plant life: after a hot drift, chillers and compressors slam back to max, increasing starts per hour and shortening lifespan.

- Energy budgets: reheating–recooling cycles waste kilowatt-hours; plant ramps draw peak tariffs.

- Resilience: every extra minute of “ride-through” without comfort loss buys you time to fix faults or ride out demand-response events.

How vacuum insulation slows the spike (without rebuilding the façade)

Think of two levers: lower the heat coming in; buffer what still gets in. Vacuum solutions do both in very thin packages.

At the glass line (fast, reversible)

- Vacuum-Insulated Curtain (VIC): a draw-at-night or peak-sun barrier that cuts conductive and radiant transfer from glazing.

- In a glass atrium like Scenario B, reducing glazing-related gains by ~33% can extend time to +8 K from ≈20 min to ~30 min; ~50% reduction stretches that to ≈39 min. That is extra diagnosis and recovery time without occupant distress.

- Vacuum-Insulated Heatable Curtain (VIHC): same insulation plus gentle radiant warmth for shoulder seasons or over-cooled spaces, at ≈1 kWh for 3 h.

In the opaque envelope (planned works)

- Decorative Integrated VIP (DVIP): an A1-capable cladding panel around 30 mm thick that slashes U-values and blocks solar heating of the structure; ideal when you want a new façade finish and safety class together.

- Flexible VIP inserts: thin, shaped vacuum panels in spandrels, mullion covers, door leaves and duct linings where thick insulation will not fit.

Inside the space (targeted buffers)

- Vacuum-Insulated Wallpaper (VIW): ~4 mm lining on hot-face walls and bay returns facing western sun; reduces radiant asymmetry occupants feel long before thermostats show it.

Practical playbook for a 40 °C city day

- Map the hotspots. Which zones go first when plant stops—glass lobbies, corner suites, sky bars?

- Install draw-down barriers. Fit VIC on critical panes; add side returns to choke edge leakage; keep stack-back clear for daytime views.

- Treat the west. Use VIW on sun-loaded returns and internal bulkheads; this is where guests feel heat at 4–6 pm.

- Plan façade upgrades. Where you need a new outer face anyway, specify DVIP to lock in low U-values with an architectural finish and the fire class you require.

- Tune operations. With barriers in place, reset supply air and set-points modestly; you often maintain comfort with less aggressive cooling and fewer compressor starts.

- Write the outage SOP. If chillers trip: draw VIC, shed non-critical loads, open buffer zones; the extra 10–20 minutes can avert a cascade of complaints.

New use cases you may not have considered

- Airport curbside and check-in halls: draw VIC during heat-wave peaks to keep queues tolerable while plant is reset.

- Sky lounges and rooftop restaurants: west-facing glass treated with VIC/VIW to blunt late-afternoon spikes without sacrificing views by day.

- Healthcare reception and triage: VIC buys time during grid wobbles; VIBB keeps 2–8 °C routes in band during lift delays.

- Convention centres: deploy VIC on perimeter halls; use DVIP on retrofitted façades to stabilise massive internal loads.

- Education blocks: exam halls with big panes hold stable longer with VIC; fewer pupil complaints, fewer invigilation disruptions.

Objections answered quickly

- “Will curtains make it dark?” Open by day; draw for peak sun or outages. Choose light decorative faces if evening brightness matters.

- “Is vacuum tech fragile?” Treat it like premium equipment. Protected layers and cassettes are designed for daily operation in public spaces.

- “What about cleaning and fire codes?” Finishes are specified for wipe-down regimes; DVIP supports A1 configurations—match product to the risk class.

What to do this month

- Pilot one lobby: instrument temperature and chiller starts for two weeks; add VIC and compare time-to-overheat and post-outage recovery.

- Patch the worst returns: apply VIW to the hottest internal returns; verify with a simple infrared snapshot before and after.

- Scope a façade lot: where recladding is planned, run a DVIP option with U-value, fire class and programme benefits in one package.

Ready to lift comfort and resilience—without ripping out glass?

- Contact our Customer Service Team for drawings, sizing, and a quick heat-gain sketch for your spaces.

- Prefer to talk it through? Speak directly with Professor Saim Memon by email or phone for a site-specific plan and payback outline.

- Explore products, specifications, purchasing steps, videos and FAQs at www.sanyoulondon.com.

A few millimetres of the right insulation at the right place can turn a fifteen-minute crisis into a manageable half-hour—often the difference between smooth operations and a lobby full of complaints.

Share

Author

Prof. Dr. Saim Memon

PhD, CEng, FHEA, MSc, BEng(Hons), PGC-TQFE, GTCS, MCMI, MIET, MIEEE, MInstP, IBPSA, APCBEES, MPEC

CEO | Industrial Professor | Inventor | British Scientist | Chartered Engineer | Qualified Teacher | Chief Editor | World Speaker | Pioneer in Vacuum Insulation Energy Technologies