What is a Vacuum Insulation Panel (VIP)?

A Vacuum Insulation Panel (VIP) is an advanced insulation element made from a microporous core—typically super-fine fibreglass with getter and desiccant, or fumed silica—that is edge-sealed inside a gas-tight envelope. The air inside is evacuated to below 10 pascals, which suppresses heat transfer through the gas; a reflective aluminium barrier reduces radiative heat; and the getter/desiccant maintain the vacuum for an ageing life of at least 25 years.

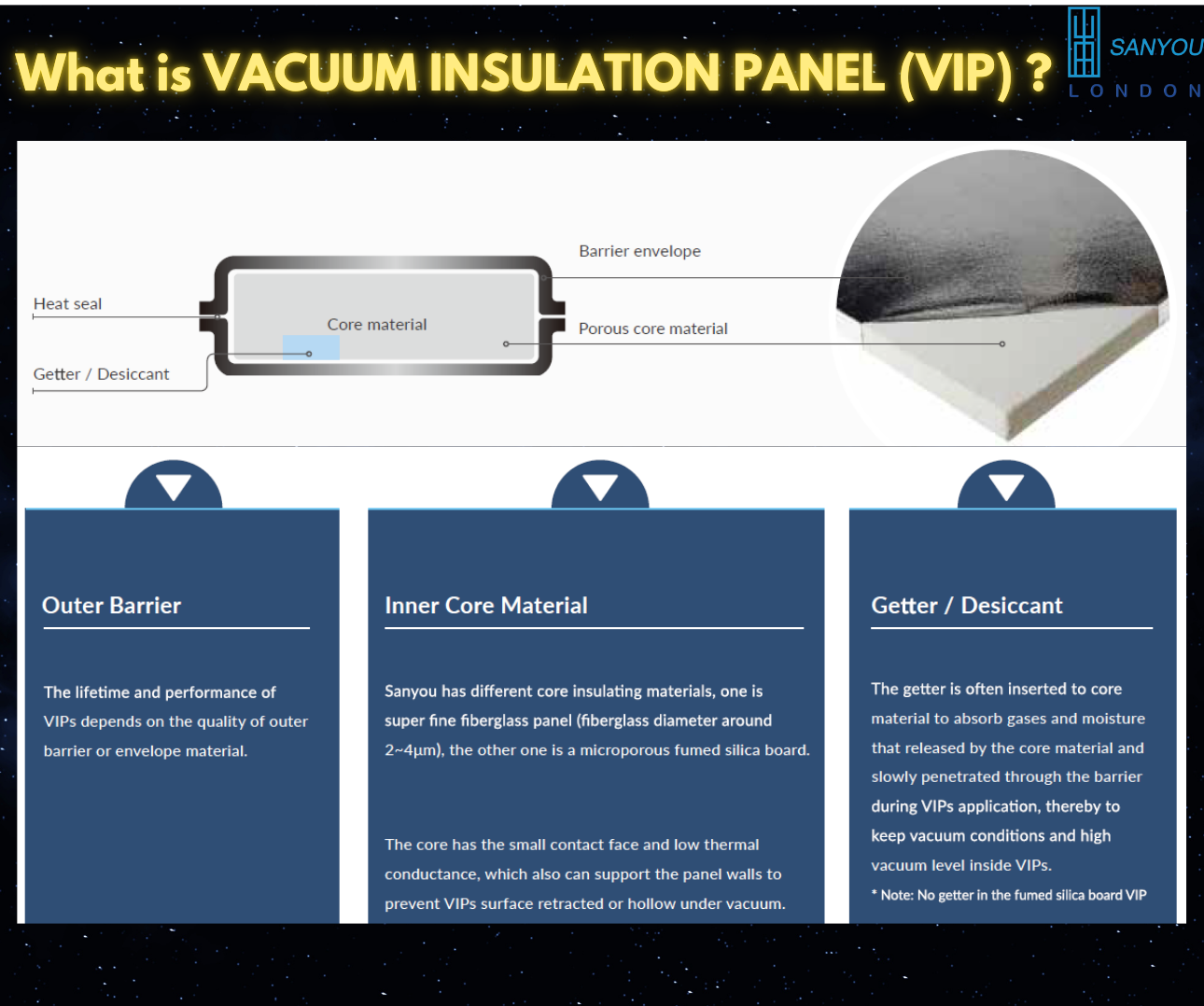

What is inside a VIP—and what does each part do?

1) The core

- Options: super-fine fibreglass with integrated getter/desiccant, or microporous fumed silica.

- Purpose: provides a rigid, porous scaffold so the skins can withstand atmospheric pressure without collapsing; keeps solid conduction very low.

2) The gas-tight envelope

- Construction: multi-layer barrier film with aluminium foil or metallised layers; sometimes metallic skins for specialist duties.

- Purpose: blocks air and moisture ingress; forms the chamber in which we hold the vacuum.

3) The edge seal

- Construction: dual-seal geometry and heat-sealed seams designed for longevity.

- Purpose: protects the most vulnerable diffusion path; keeps the panel airtight for decades.

4) The vacuum

- Operating pressure: typically 1–10 Pa (a “moderate” technical vacuum).

- Effect: at such low pressure, the mean free path of air molecules becomes millimetres, so gas conduction and convection collapse. That is why a VIP achieves such low effective thermal conductivity in so little thickness.

5) Reflective aluminium barrier

- Purpose: reduces radiative heat transfer across the core by reflecting infrared energy; partners with the vacuum to minimise the last two heat paths (radiation and solid conduction).

6) Getter and desiccant

- Getter: absorbs non-condensable gases (oxygen, nitrogen, hydrogen, etc.) that slowly diffuse in through the barrier or are released from the core over time—this limits outgassing and holds pressure low.

- Desiccant: adsorbs moisture that permeates slowly through the barrier film across years; keeps the internal environment dry, which is essential for stability.

- Outcome: together they maintain the vacuum pressure, supporting an ageing life ≥ 25 years when the panel is used and protected as specified.

Why does a VIP insulate so well?

Heat crosses an element by three mechanisms:

- Conduction in solids and gases;

- Convection (bulk air movement);

- Thermal radiation.

A VIP nearly removes the gas (vacuum), so gas conduction and convection fall to negligible levels. The microporous core minimises solid conduction, and the reflective barrier trims radiation. The combined effect is ultra-low effective thermal conductivity in a thickness measured in millimetres, rather than centimetres.

How long does a VIP last—and what really limits life?

A VIP’s life is governed by permeation (tiny amounts of air and moisture diffusing through the barrier over time) and any outgassing from the core. The getter/desiccant are sized to capture those intruders for decades, keeping the internal pressure low and the performance high. If a panel is punctured, it will take on air and lose its vacuum—hence the need for protective skins, cassettes and planned fixing zones in real projects.

Can I cut or drill a VIP on site?

No. A VIP is a sealed vacuum vessel. Cutting or drilling will vent the vacuum and void performance. We manufacture to exact sizes and shapes, including curves, tapers and precision cut-outs, so the panel arrives ready to install. Where site tolerance is needed, we design allowances and trims rather than field-cutting.

What does “dual edge-sealed” mean in practice?

Edges are the toughest design challenge. A dual edge-sealed VIP uses two complementary sealing layers (or a seal plus a secondary defence) to resist long-term ingress at the seam. It is not just about the sealant; it is the geometry, pressure control, and barrier selection that together deliver a 25-year ageing life.

What performance should I expect?

Exact figures depend on core type, thickness, skins and temperature band, but VIPs operate in the single-digit mW·m⁻¹·K⁻¹ class—orders of magnitude better per millimetre than conventional bulk insulation. The real advantage is performance in minimal depth, which protects usable floor area, window proportions and service clearances.

Where would I use VIPs?

- Space-constrained walls and façades: when you must hit a low U-value without thickening reveals.

- Spandrels, door leaves, duct and cabinet liners: thin profiles; high resistance.

- Precision equipment and temperature-sensitive transport: where every watt of heat ingress matters.

- Interior upgrades: pair with vacuum-insulated curtains at glazing lines or thin decorative systems where disruption must be minimal.

How do I specify VIPs properly?

- Dimensions and tolerances: length, width, thickness; edge offsets for fixings.

- Core selection: super-fine fibreglass with getter/desiccant, or fumed silica, based on temperature and mechanical needs.

- Barrier and finish: aluminium-barrier films, metallic skins, or cassette systems depending on duty, hygiene and fire strategy.

- Target metrics: effective thermal conductivity, design U-value of the assembly, and ageing life requirements.

- Integration details: joints, corners, reveals, and no-penetration zones; adhesive compatibility; protection during handling.

Quick Q&A

Does the vacuum make it sound-insulating too?

It can reduce airborne sound transmission through the panel; structure-borne paths depend on skins and fixings—designed case by case.

Is a VIP non-combustible?

Fire performance is a system property. The core may be non-combustible, but the overall classification depends on the skins, adhesives and assembly. We provide configurations to meet your required class.

What happens if a panel fails?

Modules are replaceable. We design access and protection so service events are rare and manageable.

Next steps—turn the principle into a specification

- Contact our Customer Service Team for samples, sizing advice, CAD details and a project-specific performance sketch.

- Prefer a direct technical discussion? Email or phone Professor Saim Memon to review drawings, duty conditions and ageing-life targets.

- Explore full product specifications, purchasing steps, videos and FAQs at www.sanyoulondon.com.

A VIP is not just “insulation”; it is a carefully engineered vacuum system that keeps heat where you want it for decades—thin, precise, and dependable.

Share

Author

Prof. Dr. Saim Memon

PhD, CEng, FHEA, MSc, BEng(Hons), PGC-TQFE, GTCS, MCMI, MIET, MIEEE, MInstP, IBPSA, APCBEES, MPEC

CEO | Industrial Professor | Inventor | British Scientist | Chartered Engineer | Qualified Teacher | Chief Editor | World Speaker | Pioneer in Vacuum Insulation Energy Technologies