What happens when you apply a Vacuum Insulation Panel (VIP) on concrete, brick and cavity walls?

Short answer: the wall stops behaving like a sieve. Below, I set out the before/after numbers exactly as you drafted them, then translate those figures into operational outcomes a designer, facilities manager, or homeowner can use.

First—what do these figures represent?

- Effective thermal conductivity here is a single, comparable number for the whole layered build-up (wall + VIP). It helps non-specialists grasp the scale of change.

- U-value is the correct measure for assembly heat flow. Lower is better.

- For quick intuition, the heat leaving a surface scales with U × area × temperature difference.

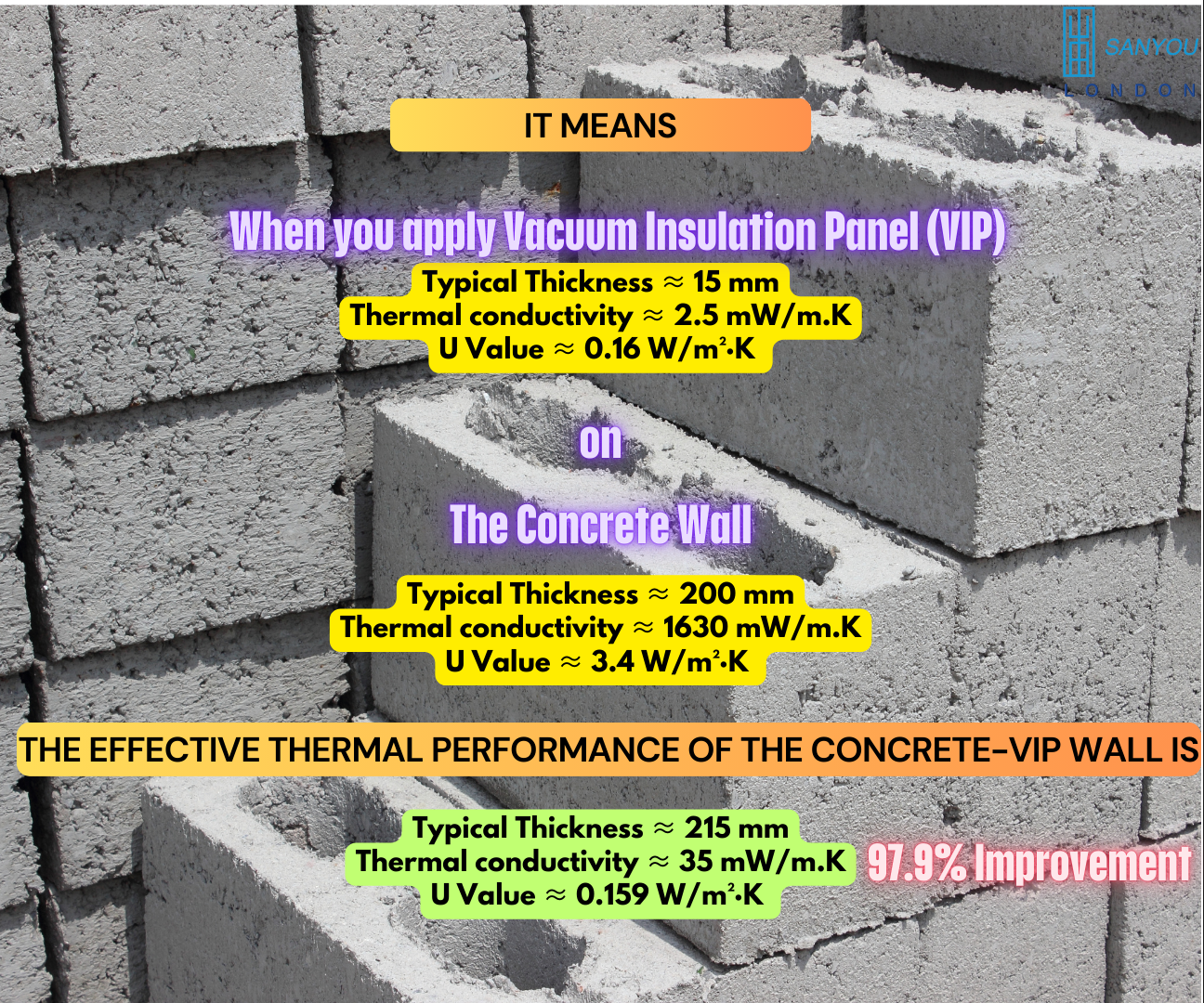

Concrete wall → Concrete + VIP (your test case)

- Effective conductivity: 1,630 → 35 mW·m⁻¹·K⁻¹

Improvement: 97.9% - U-value: 3.40 → 0.159 W·m⁻²·K⁻¹

What this means in use

With a winter ΔT of 20 °C, heat flow drops from ≈68 W/m² to ≈3.2 W/m². Across 10 m² of wall, that is roughly 650 W less heat bleeding out whenever the room is at temperature—quieter plant, steadier comfort, and lower bills.

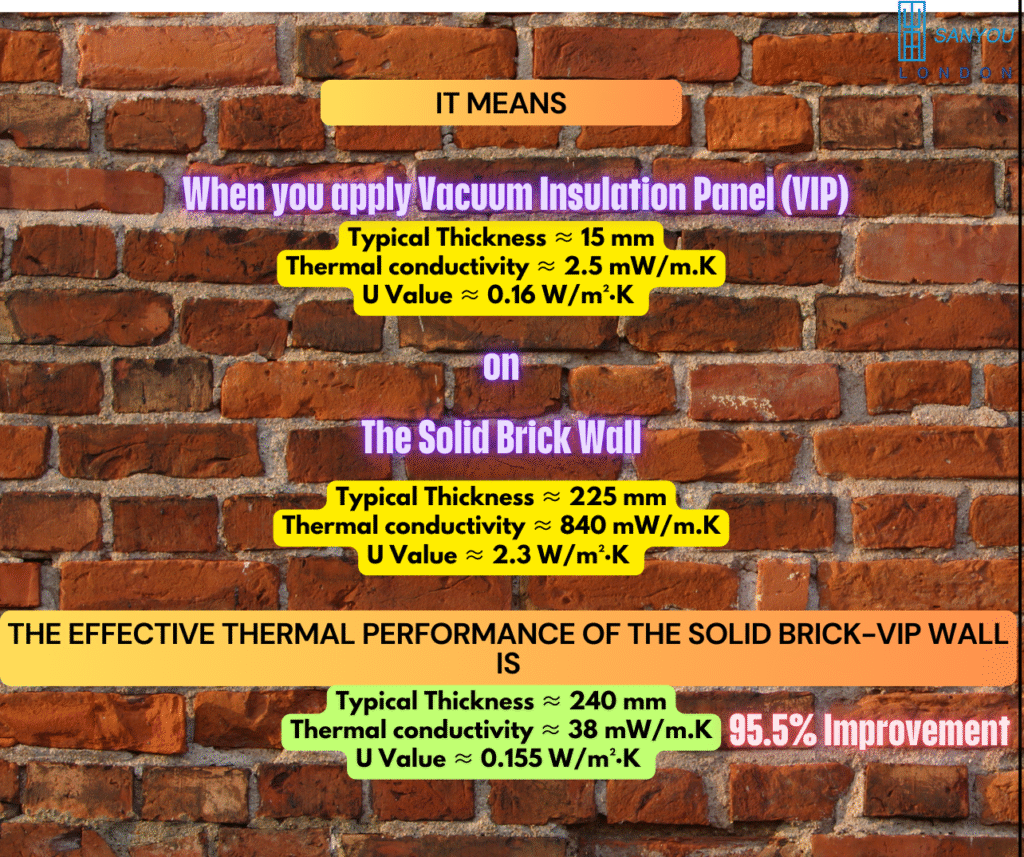

Solid brick wall → Brick + VIP

- Effective conductivity: 840 → 38 mW·m⁻¹·K⁻¹

Improvement: 95.5% - U-value: 2.30 → 0.155 W·m⁻²·K⁻¹

Meaning

At the same ΔT 20 °C, heat flow falls from ≈46 W/m² to ≈3.1 W/m²—about 43 W/m² saved. Rooms stop feeling “cold at the edge”, and heating runtimes shorten.

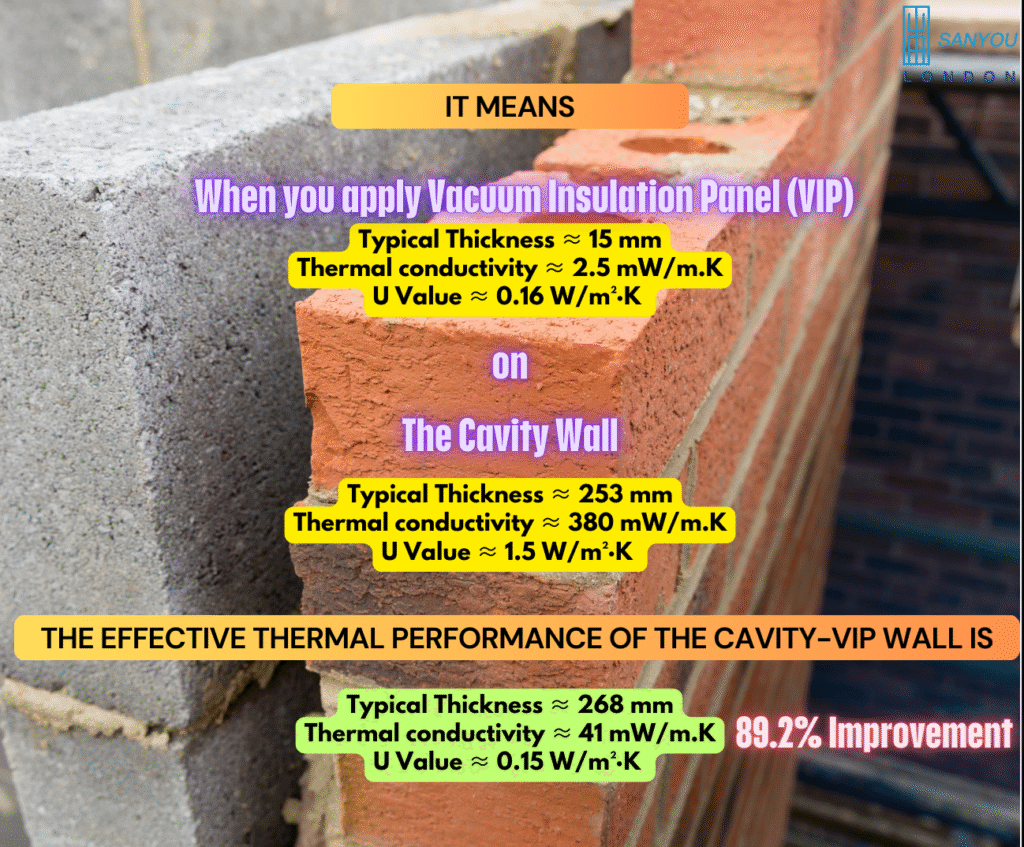

Cavity wall → Cavity + VIP

- Effective conductivity: 380 → 41 mW·m⁻¹·K⁻¹

Improvement: ≈89.2% - U-value: 1.50 → 0.150 W·m⁻²·K⁻¹

Meaning

Heat flow at ΔT 20 °C falls from ≈30 W/m² to ≈3.0 W/m²—a 90% reduction in U-value terms. Summer ingress also slows, so cooling cycles soften.

Why the U-value collapses (in plain English)

A VIP is a sealed, thin element in which the air is largely removed. With very few gas molecules present, gas conduction and convection collapse; a microporous core keeps solid conduction low; reflective barriers trim radiation. The result is single-digit mW·m⁻¹·K⁻¹-class performance in millimetres, not centimetres.

How to apply these numbers on a real project

1) Target rooms first, not whole buildings.

Select the coldest or hottest rooms by experience or a quick thermal image. Treat those external walls with VIP; you will notice the difference the same week.

2) Choose the fitting route that suits your constraint.

- Internal lining: ultra-thin VIP formats preserve net internal area and keep reveals civilised—ideal for heritage interiors.

- External finish: where a new façade face is desirable, specify decorative VIP systems to combine insulation and exterior aesthetics in one scope.

3) Tie off the weak links.

Junctions matter. Return the lining into window reveals and around sockets so heat cannot bypass the layer.

4) Pair the wall fix with the glass line.

Even superb walls can be let down by glazing. Add a vacuum-insulated curtain for evening and peak-sun periods; together, wall + window line form a balanced envelope.

Fresh, practical scenarios (so you can brief a site team)

- London terrace front room: One external brick wall + bay. Add VIP on the wall, then draw the vacuum curtain at dusk. Expect a calmer evening temperature at the same thermostat setting—and fewer complaints about “cold corners”.

- Manchester loft concrete party wall: Treat the cold concrete flank with VIP. You retain floor area while removing the “radiant chill” that prompts occupants to crank the heating.

- Doha apartment with a cavity wall on west elevation: VIP lining the internal face reduces late-afternoon heat ingress; the AC coasts rather than slams back to full output after short outages.

Is the comparison fair?

Yes—for the same wall before and after the same VIP layer. Results will vary with wall thickness, surface films, fixings and workmanship, so we always provide project-specific U-value calculations and detailing notes to lock in the gains you see above.

Quick answers to predictable questions

Can I cut a VIP on site?

No; it is a sealed element. We manufacture made-to-size panels, including curves and service cut-outs, so site work remains tidy.

What about fire classification?

Fire is an assembly property. We supply configurations to meet your strategy, including A-class façadable options.

What if a panel is damaged later?

Panels are protected by design and replaceable in modules; we plan no-penetration zones and access so maintenance is straightforward.

Ready to translate figures into drawings and budgets?

- Contact our Customer Service Team for samples, detailing, U-value sketches and tailored pricing for your wall build-ups.

- Prefer a direct conversation? Email or phone Professor Saim Memon to review drawings and sequence a low-disruption retrofit.

- Explore products, specifications, purchasing steps, videos and FAQs at www.sanyoulondon.com.

Side-by-side, our VIPs deliver target U-values in millimetres that foams and wools need centimetres for—saving space, weight and energy without compromising fire strategy.

Share

Author

Prof. Dr. Saim Memon

PhD, CEng, FHEA, MSc, BEng(Hons), PGC-TQFE, GTCS, MCMI, MIET, MIEEE, MInstP, IBPSA, APCBEES, MPEC

CEO | Industrial Professor | Inventor | British Scientist | Chartered Engineer | Qualified Teacher | Chief Editor | World Speaker | Pioneer in Vacuum Insulation Energy Technologies