Vacuum Insulated Bag-or-Box (VIBB): A Practical Innovation for Real Impact in Temperature-Sensitive Transport, Storage, and Energy Saving

We built VIBB to turn solid science into everyday reliability—so you can move sensitive goods with confidence while using less energy.

Why did we create VIBB when there are already boxes and coolers?

Because familiar options often rely on ice, power, or thick foam—and still struggle when routes are long, ambient conditions are harsh, or handling is frequent. VIBB applies flexible Vacuum Insulation Panel (VIP) technology to packaging, so you get the kind of thermal hold you expect from a vacuum flask—but sized for medical, food, agricultural, and chemical logistics.

In simple terms: a vacuum is an excellent barrier to heat flow. By integrating flexible VIPs into bag-and-box formats, VIBB helps keep the inside in range—hot or cold—without relying on ice, refrigeration, or electricity, provided contents are pre-conditioned to the target temperature.

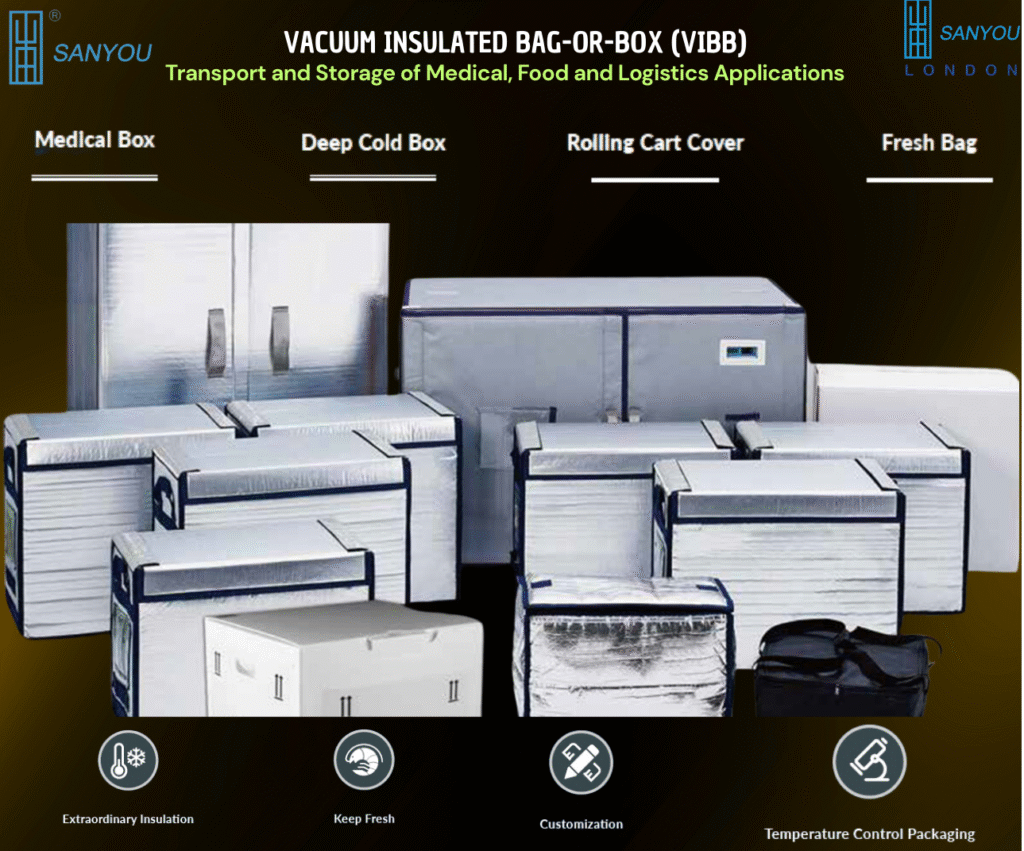

The VIBB family—four solutions for different duties

1) VIBB Medical Box

- Performance (test result): maintains 2–8°C for about six days with pre-chilled contents at +25°C ambient.

- Use cases: vaccines, temperature-sensitive medicines, diagnostic samples, clinical outreach.

2) VIBB Deep Cold Box

- Performance (test result): holds target temperatures for around three days at +30°C ambient.

- Use cases: fresh and frozen foods, fisheries and farm produce, catering, e-commerce cold chain.

3) VIBB Rolling Cart Cover

- Performance (test result): at +35°C ambient, maintains <10°C for 15 hours on loaded carts.

- Use cases: event catering, hotel and hospital services, agricultural logistics, emergency relief staging.

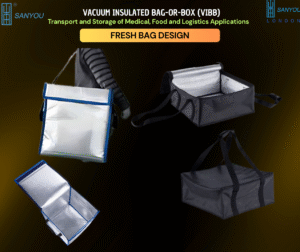

4) VIBB Fresh Bag

- Performance (test result): at +35°C ambient, keeps pre-chilled food <10°C for up to 6.5 hours.

- Use cases: delivery riders and couriers, grocery runs, picnics, gym days, hikes—keep it cold until you are ready.

Picture this: you stop at the gym and your groceries stay fresh in the Fresh Bag—or you open a warm packed meal at the summit without lugging powered gear.

What problems does VIBB actually solve?

- Energy use: fewer powered boxes and less reliance on vehicle refrigeration reduces fuel and electricity demand.

- Temperature drift: vacuum insulation cuts heat ingress, so ranges are held for longer with fewer interventions.

- Operational friction: no cables, no generators, fewer consumables—simpler standard operating procedures.

- Waste and spoilage: tighter control means fewer discards, better patient safety and food quality, and less cost.

How does VIBB work behind the scenes?

Each VIBB format uses a multi-layer barrier with flexible VIPs, integrated into a protective outer designed for routine handling. Seams and closures are engineered to minimise thermal bridges, and the internal geometry supports stable packing so air voids are reduced.

Good practice matters: pre-condition contents to the target band; load densely; avoid unnecessary lid openings; keep the unit shaded where possible. These simple steps extend the hold time you achieve in the field.

Quick specification snapshot

- Medical Box: 2–8°C for ~6 days at +25°C ambient with pre-chilled contents.

- Deep Cold Box: ≈3 days at +30°C ambient.

- Rolling Cart Cover: <10°C for 15 hours at +35°C ambient.

- Fresh Bag: <10°C for up to 6.5 hours at +35°C ambient with pre-chilled contents.

Field results will vary with load mass, packing pattern, opening frequency, ambient peaks, radiation exposure, and start temperature. We can help you model your specific route profile.

Where VIBB helps most—by sector

Healthcare and life sciences

- Outreach vaccination, primary care, pharmacy transfers, temperature-controlled home delivery.

- Supports GDP workflows; ask us for route-validation guidance and documentation templates.

Food and beverage

- Farm-to-market runs, last-mile delivery, catering lines, hospitality service points.

- Lower energy, fewer rejects, cleaner operations where power is limited or unreliable.

Logistics and emergency response

- Staging hubs, rapid deployment, disaster relief where cold chains are stressed or absent.

- Rolling Cart Cover keeps large batches within range during load, stage, and serve windows.

FAQs

Do I need ice packs or power?

VIBB is designed to avoid reliance on ice or power. For extreme ambient conditions or unusually long routes, optional thermal buffers can be added—speak to us and we will advise.

Can VIBB hold warm items too?

Yes. Pre-heat the contents to your target temperature and load promptly; the vacuum insulation slows heat loss just as it slows heat gain.

How rugged is it?

Outer shells are specified for the duty cycle. For high-frequency use, we recommend reinforced corners and serviceable liners.

Is cleaning straightforward?

Yes. Choose wipe-clean internal finishes for food or clinical use; we can recommend compatible sanitisers and cleaning cycles.

Can you help with validation?

Absolutely. We provide thermal guidance, route-specific hold-time estimates, and data-logging support for trials.

Ready to run a route test—or place an order?

- Contact our Customer Service Team for specifications, pricing, CAD support, samples, and route-validation assistance.

- Prefer to speak directly? Contact Professor Saim Memon by email or phone to discuss your application, temperature bands, and duty cycle.

- Explore the full VIBB range, purchasing process, videos, and FAQs at www.sanyoulondon.com.

If your work depends on temperature control, VIBB gives you a quieter, simpler way to keep products safe—without the plug, the ice, or the stress.

Share

Author

Prof. Dr. Saim Memon

PhD, CEng, FHEA, MSc, BEng(Hons), PGC-TQFE, GTCS, MCMI, MIET, MIEEE, MInstP, IBPSA, APCBEES, MPEC

CEO | Industrial Professor | Inventor | British Scientist | Chartered Engineer | Qualified Teacher | Chief Editor | World Speaker | Pioneer in Vacuum Insulation Energy Technologies