VIBB Rolling Cart Cover: Design, Performance and Applications

What it is—and why it matters

The VIBB Rolling Cart Cover (Sanyou London) is a large-format, vacuum-insulated sleeve that slips over a standard roll cage, bakery rack, banquet trolley or produce cart. In minutes, a routine trolley becomes a mobile temperature-controlled store—no plug-ins, no diesel, no dry ice. It is engineered for dual-purpose service: keep pre-chilled goods cold or, with suitable phase-change heat packs, hold dishes warm during service runs.

Construction: built to work hard, day after day

- Thermal core: multi-layer flexible Vacuum Insulation Panels (VIPs) arranged to minimise conduction paths at corners and seams.

- Protective skins: tear-resistant outer fabric with a wipe-clean inner liner for quick sanitising; optional smooth, food-safe inner for heavy catering use.

- Closures: full-height zips or quick-access magnetic flaps; storm overlaps to limit air ingress during short openings.

- Reinforcement: corner bumpers, base wear pads, and optional wheel-plate guards for rough floors and kerbs.

- Operational features: clear document window, data-logger pocket at mid-height, colour bands for route coding, and internal PCM sleeves for either cold or hot pack modules.

- Organisation: removable divider curtain to create two temperature zones; optional shelf rails for gastronorm pans or produce crates.

Result: strong thermal resistance in millimetres, wrapped in a shell that tolerates knocks, wash-downs and frequent loading.

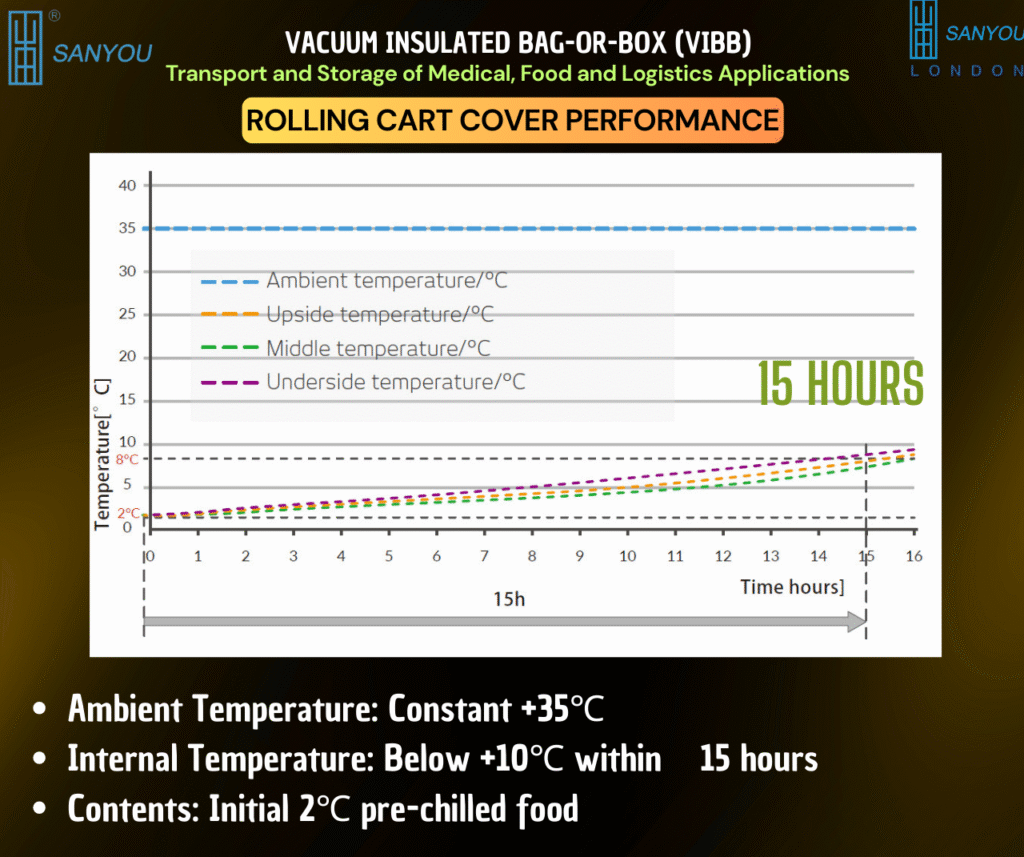

Performance: stated plainly

With pre-chilled contents at 2 °C and ambient at +35 °C, the Rolling Cart Cover maintained internal temperatures below 10 °C for about 15 hours, assuming disciplined door practice during runs. That is enough for full-day events, multi-stage banqueting, farm-to-market trips, and last-mile operations that extend beyond a single shift.

For hot service, use high-temperature PCM packs in the dedicated sleeves to support safe hot holding in line with your HACCP policy. Target service temperatures are set by your food-safety plan; our team supplies compatible pack specifications and placement guidance.

What changes duration? Payload mass, start temperature, opening frequency, ambient profile, and packing density. We provide pack-out tables and a simple validation script so you can prove performance on your route and document it for audit.

Where it earns its keep—sector snapshots

Catering and event management

- Use: transport salads, desserts, and plated courses from prep kitchen to ballroom or stadium tiers.

- Gain: fewer trips back to fridges; smoother plating; shorter queues. The cover acts as a quiet, mobile cold room parked beside the service point.

Agricultural produce and fresh markets

- Use: field-harvested fruit and vegetables travel from farm to auction or distribution centre without heat soak.

- Gain: fewer grade downgrades, firmer textures, and better shelf life. Farmers can load straight into roll cages and wheel through the chain.

Retail back-of-house and dark stores

- Use: stage chilled orders near the loading bay; run multi-drop loops without a reefer van.

- Gain: lower fuel or plug-in costs and less congestion at the dock; reliable temperature traces for customer assurance.

Emergency and disaster relief

- Use: rapid deployment of food, water, or temperature-sensitive supplies to affected areas where power is unreliable.

- Gain: fast set-up—no generators, no cabling—so teams focus on distribution, not equipment.

A practical operating routine (cold service)

- Pre-condition the payload to the target band; if using PCMs, condition them to the specified set-point.

- Stage the cart in a shaded, cool area; slide liner trays and dividers into place.

- Load tight—fill from the base up; avoid voids; keep frequently accessed items near the door.

- Logger in—place the data logger in the insulated pocket at mid-stack; start the trace.

- Seal and label—close flaps fully; fit tamper tabs if required; mark route and contents clearly.

- Door discipline—plan pick sequence; open only as far as needed; re-seal immediately.

- Handover—at the venue, park the cart in shade; log final temperatures before service.

For hot service, swap in high-temperature PCMs, confirm placement, and log initial core temperatures as per your HACCP plan.

Sizes, variants and accessories

- Footprints: tailored to common roll cages, bakery racks and banquet trolleys; custom heights for mezzanine doors and lifts.

- Closures: zip or magnetic; single or double front; optional side service flap for rapid picks.

- Internal fit-out: divider curtains, shelf rails, GN pan frames, crate stops, and anti-tip straps.

- Identity & tracking: colour trims by route, QR or bar-code asset IDs, and RFID options for fleet systems.

- Packs: matched cold or hot PCM modules; spare liners and gasket kits for mid-life refresh.

Hygiene, safety and durability

- Cleaning: smooth inner faces accept neutral detergents and common sanitisers; seams are sealed for quick wipe-downs.

- Food safety: the logger pocket places the probe near the thermal centre for credible traces; documentation fits standard HACCP files.

- Repairability: corners, zips and liners are service-replaceable; components carry their own part numbers so maintenance is easy to order.

What operators typically measure—and how it pays back

- Temperature excursions: fewer off-spec events reduce write-offs and customer complaints.

- Fuel or plug-in use: passive hold cuts reefer hours or eliminates them for short runs.

- Labour time at service points: fewer back-and-forth trips to fixed cold rooms.

- Throughput and guest experience: steadier service pacing, shorter wait times, and better reviews.

A one-week pilot with logging and simple time-and-motion notes is usually enough to convince finance and operations.

Frequently asked by teams on the ground

Will condensation build up inside?

Pack dry items in lidded containers; the liner is wipe-clean. After service, leave the cover open to air before storage.

How heavy is it?

The cover adds very little mass relative to its capacity. You’re moving payload, not packaging.

Can it run mixed hot and cold?

Yes—with the divider curtain fitted and the correct PCM placement. We provide a layout sketch for your menu or route.

Is it weatherproof outdoors?

The cover resists showers and sun exposure during normal handling. For sustained rain, use the optional rain shroud.

Ready to turn your trolleys into mobile cold or hot stores?

- Contact our Customer Service Team for specifications, pack-out tables, validation scripts, and tailored price quotations.

- Prefer a direct conversation? Email or phone Professor Saim Memon to map sizes to your roll cages, menus and routes; we will design a measured pilot that your board can approve.

- Explore the full VIBB range, purchasing steps, videos and FAQs at www.sanyoulondon.com.

Thin insulation; big outcomes. The VIBB Rolling Cart Cover keeps food safe, service smooth and logistics simple—where power is scarce, time is short, and reliability matters.

Share

Author

Prof. Dr. Saim Memon

PhD, CEng, FHEA, MSc, BEng(Hons), PGC-TQFE, GTCS, MCMI, MIET, MIEEE, MInstP, IBPSA, APCBEES, MPEC

CEO | Industrial Professor | Inventor | British Scientist | Chartered Engineer | Qualified Teacher | Chief Editor | World Speaker | Pioneer in Vacuum Insulation Energy Technologies