VIBB Deep Cold Box: Design, Performance and Applications

Why a Deep Cold Box at all?

Refrigerated vans and reefers are not always available, economical or welcome at delivery bays. Doors stand open; routes change; plug-in points are scarce. VIBB Deep Cold Box (Sanyou London) gives operators a compact, power-free way to hold safe temperatures through the awkward hours between depot, cross-dock and shelf.

Materials and build: what makes it different

- Hybrid wall: PU–VIP composite, combining polyurethane for structure and impact tolerance with vacuum-insulated panels for ultra-low thermal conductivity. In practical terms, this wall delivers roughly five times the insulating performance per thickness compared with typical XPS panels of similar build.

- Variants: foldable shells for back-haul and storage efficiency, and rigid shells for heavy, high-turn work.

- Protection: reinforced corners, ribbed liners, replaceable gaskets, and a wipe-clean outer skin that tolerates routine sanitisers.

- Fleet features: tamper-evident closures, document window, integrated pocket for data loggers, dedicated sleeves for phase-change packs when routes or compliance demand them.

- Footprints: crate, parcel and pallet footprints to drop straight into roll cages, stillages and van racking without re-engineering the vehicle.

Proven performance—stated plainly

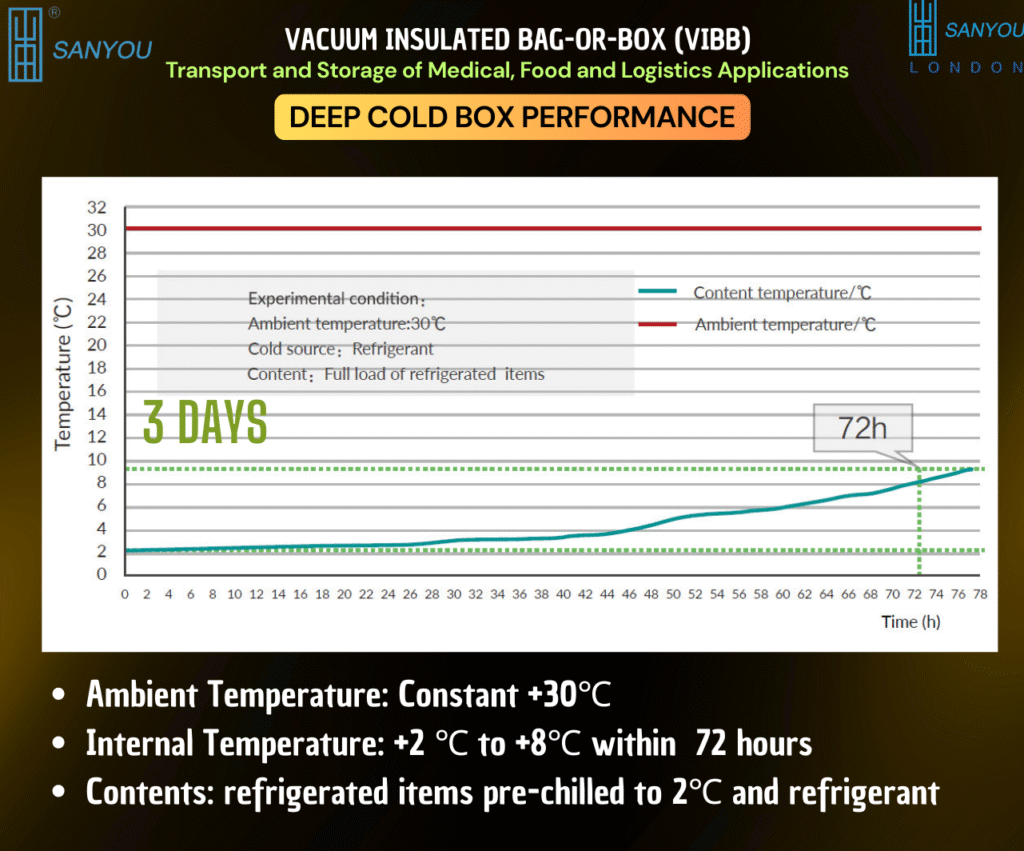

In controlled trials at plus 30 degrees Celsius ambient, with the payload pre-chilled to two degrees, the VIBB Deep Cold Box held the internal band of two to eight degrees for three full days. That is a realistic, route-friendly duration for weekend bridges, long handovers and weather delays.

What determines your real-world duration? Payload mass and start temperature, outside climate, box size, pack-out tightness and door discipline. We supply pack-out tables and a short validation script so you can prove performance on your own lanes before rollout.

Where it earns its keep

Fresh and frozen food logistics

- Distributors and retailers: ice cream, seafood, ready meals and chilled dairy ride in band without sweating at the back door while staff check-in.

- Grocery e-commerce: route flexibility without diesel reefers; fewer “too warm” returns and chargebacks.

- Catering and events: ingredients and plated dishes arrive cold at marquees and stadia; service teams focus on guests, not ice top-ups.

- Farmers and fisheries: harvest and catch travel from field or quay to pack-house with less temperature shock, improving grade and shelf life.

User workflow: a simple five-step SOP

- Pre-condition the payload to the target band; if using phase-change packs, condition them to the marked set-point.

- Stage the box in a shaded, cool area; insert packs in the sleeves as needed.

- Load tight—use dividers to remove voids and stop cartons settling.

- Insert the logger in the pocket; check time and route label.

- Seal and go—brief drivers on minimal open time at each stop.

This process fits HACCP routines and keeps records clean for audits.

Sizing and options

- Foldable series: ideal where warehouse space is tight and back-haul costs matter; folds flat in seconds.

- Rigid series: for daily multi-drop durability; stackable lids, wheel-plate options and corner guards.

- Capacities: from compact totes for last-mile runs to pallet-wide bulk boxes; all share the same PU–VIP architecture.

- Accessories: dividers, gel or phase-change packs, QR or bar-code IDs, colour bands for route sorting, trolley mounts.

Hygiene, durability and sustainability

- Cleanability: smooth liners and rounded corners speed wash-down; compatible with common food-safe sanitisers.

- Service life: replaceable gaskets and liners extend use; components carry their own part numbers for quick spares.

- Waste reduction: reusable construction displaces single-use EPS and film; fewer spoiled loads mean less food waste and fewer write-offs.

- Energy saving: passive hold reduces reefer run hours; operators see quieter yards and lower fuel or plug-in bills.

Risk control and compliance

- Temperature proof: logger pockets keep devices central to the load for credible traces; data attaches to delivery records.

- Tamper evidence: seals and lock points support chain-of-custody.

- Regulatory fit: supports HACCP programmes; dry-ice-free operation avoids handling restrictions for most food lanes. Where colder bands are mandated, we supply dry-ice-ready variants with vent notes.

Route sketches you can run tomorrow

- Ice cream to forecourts: rigid boxes ride on a standard roll cage; lids open for seconds at each stop; logger shows a tight trace after a twenty-stop loop.

- Seafood from quay to hub: foldables deployed for the morning landings, then cleaned and collapsed for afternoon back-haul.

- Event catering at a stadium: rolling racks fitted with Deep Cold Boxes deliver salads and desserts across multiple levels; staff work from one mobile cold store rather than dashing to fridges.

- Meal-kit e-commerce: order waves picked into tote-sized boxes; home deliveries complete within the three-day envelope even with weather slips.

Frequently asked by operations teams

Do we still need ice?

For the three-day profile at 30 degrees ambient with pre-chilled payloads, no. For longer or hotter profiles, use our matched phase-change packs. They are sealed, tidy and easy to condition.

How heavy are they when loaded?

That depends on your product, not the box. The PU–VIP shell is light for its performance, so you carry payload, not packaging.

Can we repair them?

Yes. Corners, gaskets and liners are service-replaceable. We offer inspection guides and parts.

Will they fit our cages and vans?

Choose from our standard footprints or request a custom size. We map the box to your roll cages, shelves and parcel tiers.

Measuring impact—make the business case in a week

- Run one route with your current packaging and one with Deep Cold Boxes.

- Compare temperature traces, returns and spoilage, fuel or plug-in use, and handling time.

- Present the combined cost and quality delta to your board. The numbers are usually decisive.

Ready to trial VIBB Deep Cold Box on your lanes?

- Contact our Customer Service Team for specifications, pack-out tables, validation scripts and a tailored price quotation.

- Prefer a direct technical conversation? Email or phone Professor Saim Memon to map sizes to your cages and vehicles and plan a measured pilot.

- Explore the full VIBB range, purchasing steps, videos and FAQs at www.sanyoulondon.com.

Bottom line: a compact, tough, PU–VIP Deep Cold Box that keeps food safely cold for days—without power, without dry ice, and without redesigning your fleet.

Share

Author

Prof. Dr. Saim Memon

PhD, CEng, FHEA, MSc, BEng(Hons), PGC-TQFE, GTCS, MCMI, MIET, MIEEE, MInstP, IBPSA, APCBEES, MPEC

CEO | Industrial Professor | Inventor | British Scientist | Chartered Engineer | Qualified Teacher | Chief Editor | World Speaker | Pioneer in Vacuum Insulation Energy Technologies