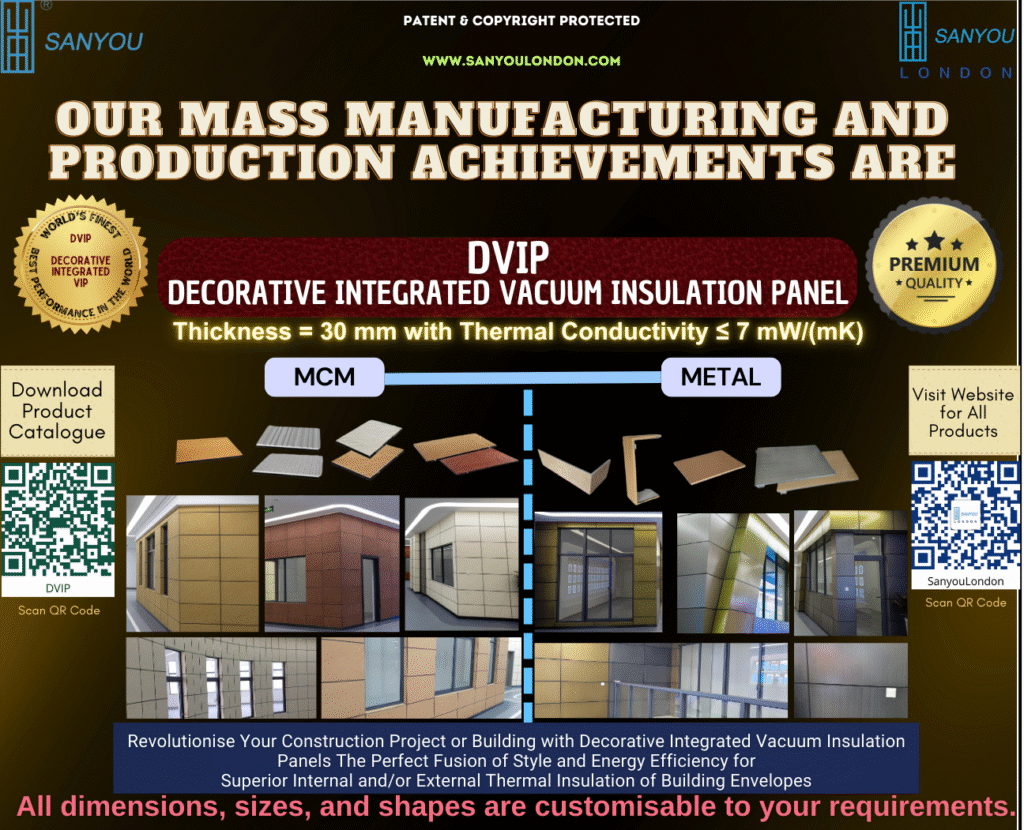

Decorative Integrated Vacuum Insulation Panels (DVIP): An All-in-One External Wall Cladding, Insulation, and Internal Roof Solution for Ultra Energy Savings

Let’s keep this simple and conversational. We all hear “climate change”, “sustainability”, and “energy efficiency” every day. Too often, the ideas stay in papers and policy briefs. My team and I focus on delivery: practical products that reduce real energy use in real buildings.

Why do we need DVIP when there are so many insulations already?

Because three persistent problems keep showing up on site:

- Fire safety risks from combustible foams;

- Low thermal performance at realistic thicknesses;

- Poor aesthetics when retrofitting façades.

DVIP tackles all three at once: a decorative, weather-resistant cladding panel with a vacuum-insulated core, engineered for external walls and internal roof build-ups where space, safety, and appearance all matter.

Challenge 1 — Fire safety: still not fully solved

In cold, arid regions such as the UK—and in many global markets—common insulations like EPS, XPS, and PU are combustible. Fire-retardant additives help, but they don’t turn a combustible core into a non-combustible one, and their effectiveness can diminish over time.

DVIP is different. It is specified with a non-combustible construction and available in A1 fire-rated configurations under EN 13501-1 (when selected in the project specification). In other words, it provides the fire performance architects and clients expect for façades—without sacrificing thermal results.

Challenge 2 — Thermal performance: do more with less thickness

Where energy efficiency is the goal, vacuum insulation is the step change. In our programme, decorative VIP systems at 30 mm achieve thermal conductivity < 7 mW/m·K (laboratory results), enabling very low U-values in slim build-ups that preserve internal floor area and simplify detailing around reveals and interfaces. Compared with conventional mineral wool or polymeric foams at the same thickness, DVIP delivers markedly higher thermal resistance.

Challenge 3 — Aesthetics: make the upgrade look premium

Traditional external wall insulation systems often need a render or cladding overbuild and can look utilitarian. DVIP integrates the decorative face with the insulation, so the façade upgrade is a single coordinated system—clean lines, durable finishes, and colourways suitable for contemporary or heritage contexts. It is insulation and architecture, not insulation hidden behind it.

Challenge 4 — Poorly insulated structural envelopes in hot-arid and cold-arid regions

From sheer concrete and brick frames to lightweight high-rises, many buildings leak heat in winter and lose cooling in summer. DVIP addresses this with:

- Superior energy efficiency from the vacuum core;

- Eye-catching, weatherable exterior finishes;

- Slim depth to respect site constraints;

- Installer-friendly formats for predictable programme delivery.

Result: lower energy bills, more stable indoor temperatures, and a façade that adds value.

What exactly is DVIP—and how is it built?

Think of DVIP as a factory-assembled sandwich panel where the vacuum-insulated core (with getter/desiccant and barrier films) is protected by robust outer skins and finished in a decorative, weather-resistant surface. Edges and fixings are engineered to avoid puncturing the vacuum core, with cassette or sub-frame systems used to manage loads, joints, and movement.

Typical specification options include:

- Panel thickness: around 30 mm (other gauges available for project needs).

- Thermal performance: λ < 7 mW/m·K at 30 mm (lab result).

- Fire performance: A1 non-combustible construction when specified.

- Finishes: architectural colours and textures for new-build and retrofit.

Where does DVIP fit best?

External wall cladding (new-build and retrofit)

- Façade refresh + deep energy cut in one package.

- Slim profiles protect floor area and ease window/reveal detailing.

- Weather-resistant outer skin with durable finish options.

- Improved EPC/energy ratings and enhanced asset value.

Internal roof insulation (cold-roof or conditioned spaces)

- High performance with minimal depth, ideal for tight plant zones and retrofits.

- Low additional load compared with heavy over-roof solutions.

- Cleaner service runs by coordinating cut-outs and penetrations during design.

How does DVIP compare with mineral wool and PIR?

- At like-for-like thickness, DVIP’s vacuum core offers much higher R-value.

- Fire performance is addressed at the system level with A1 options.

- Aesthetics are integral; you specify the visual finish you actually want.

- Programme certainty improves because the panel is factory-assembled.

Practical design notes (keep projects smooth)

- Detail early. Fixings, joints, corners, and penetrations should be coordinated to avoid puncturing the vacuum core; we provide CAD support to help.

- Control thermal bridges. Use thermally broken brackets or sub-frames where appropriate; design joints for both performance and water management.

- Specify by outcome. Target U-values, fire class, exposure, and maintenance regime; we match the DVIP build-up to those requirements.

- Plan handling. Treat DVIP as a high-performance component; use the recommended protection and lifting methods on site.

What benefits should clients expect?

- Lower heating and cooling energy, proven in operation.

- Upgraded façade that looks premium, not “afterthought”.

- Better EPC/energy certification and potential asset value uplift.

- Comfort and resilience, with steadier indoor temperatures across seasons.

Is DVIP right for your region and project type?

From the UK and Europe to Saudi Arabia, the UAE, and China, the same needs recur: strong fire performance, high insulation at low thickness, and a finish the client is proud to show. DVIP is designed precisely for that overlap—performance you can measure, appearance you can admire.

Quick Q&A

Q: Is it suitable for high-rise façades?

A: Yes—when specified with appropriate A1 configurations and fixing systems designed for wind load, movement, and drainage.

Q: Can I get colours and textures to match an existing streetscape?

A: Yes—architectural finish options are available. We can support samples for planning and client approval.

Q: What about maintenance?

A: Finishes are selected for weatherability and cleanability; maintenance cycles depend on exposure class and finish choice.

Q: Can you help with U-value calculations and details?

A: Absolutely. We provide design assistance, CAD/DWG details, and thermal modelling support for tender and technical submissions.

Ready to specify—or want to explore feasibility first?

- Speak to our Customer Service Team for guidance, samples, CAD support, and tailored pricing.

- Prefer a direct conversation? Contact Professor Saim Memon by email or phone to discuss your drawings, performance targets, and programme needs.

- Explore our full range, specifications, purchasing process, videos, and FAQs: www.sanyoulondon.com

Let’s design insulation that adapts, performs, and helps you move confidently towards a net-zero future.

Share

Author

Prof. Dr. Saim Memon

PhD, CEng, FHEA, MSc, BEng(Hons), PGC-TQFE, GTCS, MCMI, MIET, MIEEE, MInstP, IBPSA, APCBEES, MPEC

CEO | Industrial Professor | Inventor | British Scientist | Chartered Engineer | Qualified Teacher | Chief Editor | World Speaker | Pioneer in Vacuum Insulation Energy Technologies