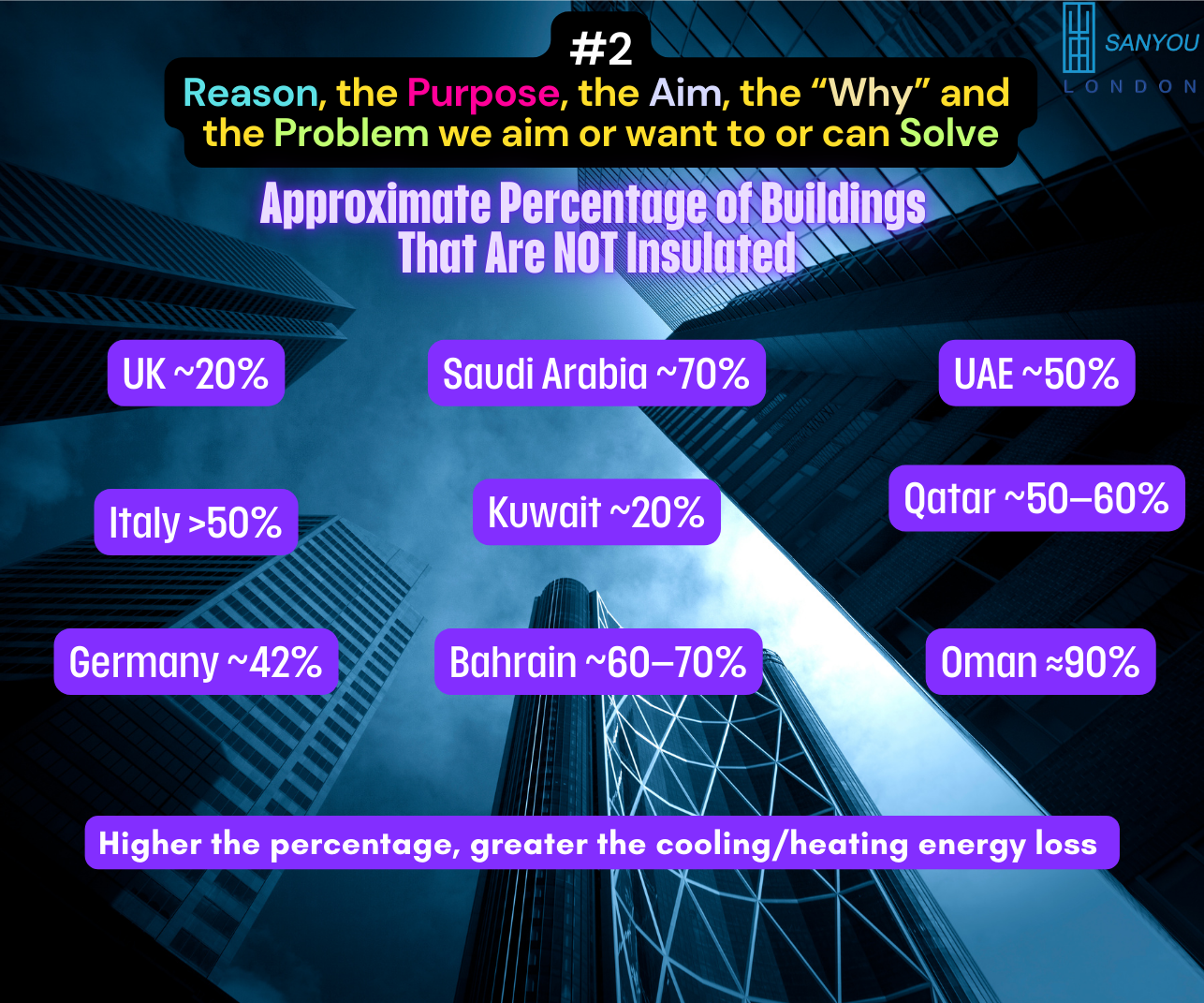

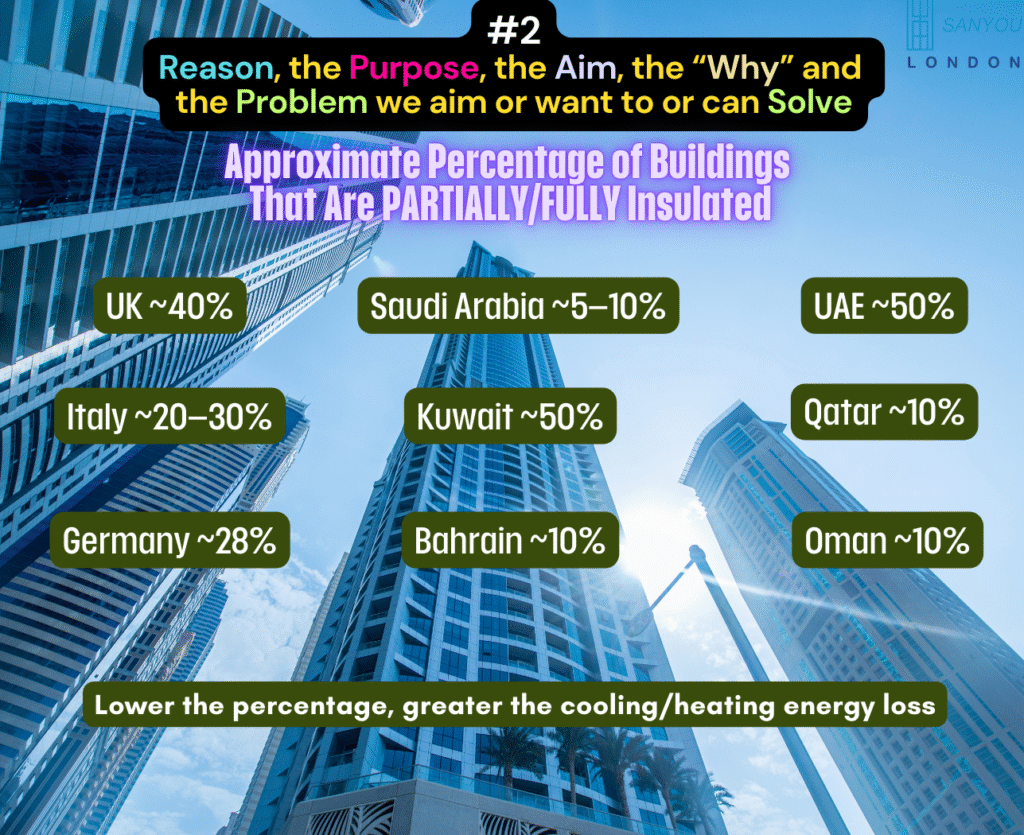

Which countries lose the most—and what the percentages really mean

The physics behind the policy: why this matters

Heat transfer through the envelope scales with U × Area × temperature difference × time. If the envelope is weak, you pay twice: first in energy and then in oversized plant to compensate. Insulation reduces the loss at the source, so every future kilowatt-hour of clean generation goes further. This is why insulate before you generate is more than a slogan; it is sound engineering.

Vacuum insulation cuts conduction and convection in the core and trims radiative transfer, giving very low thermal conductivity at minimal thickness. That is decisive where floor area, façades, reveals, glazing lines and programme constraints limit conventional approaches.

Why partial insulation still underperforms

Three practical reasons explain disappointing results in “partly insulated” buildings:

- Breaks in continuity. Gaps at window reveals, lintels, slab edges and service penetrations act as thermal bridges that bypass the main layer.

- Air leakage beats insulation. Unsealed frames, trickle vents stuck open and leaky service chases let conditioned air escape; insulation cannot compensate for uncontrolled airflows.

- Glazing dominates. A wall can be excellent, yet large, poorly treated windows set the room temperature. Treat the glass line and the whole space calms down.

This is exactly where thin, targeted vacuum solutions earn their keep—treating reveals, glazing lines and other awkward geometries that bulky insulation cannot reach.

“Energy is cheap here—why should we insulate?” Four realistic answers for the Middle East and other low-tariff regions

- Protect the assets that keep you cool. Lower cooling loss reduces compressor run-time and cycling, so air conditioners last longer and fail less often. Capital that would have gone into repairs stays on site.

- National resilience without new megawatts. Cut cooling demand by even ten percent across a city with a 2 GW summer peak and you release ~200 MW of capacity. Over five hours a day for 120 peak days, that is roughly 120 GWh avoided—fuel saved, emissions avoided, and fewer grid stress events.

- Tariffs change; buildings last. Tariffs can be low today and higher tomorrow. Buildings endure for decades to centuries. Decisions about the envelope compound in time—on comfort, cost, and value.

- Progress moves forward. Yesterday’s standard is not today’s best practice. Insulating now is a practical step towards cleaner, quieter, more reliable cooling and heating. When a better method arrives, you can layer it on top of an already efficient envelope.

Additional gains worth noting:

- Peak shaving that reduces brownout risk on the hottest afternoons.

- Water savings in regions where power and desalination are linked.

- Indoor comfort and health from steadier temperatures and fewer draughts.

- Property value and green leasing advantages as codes and ESG expectations tighten.

Country mini-briefings and where to start

United Kingdom

Older masonry, large heritage stock, high winter tariffs.

- Quick wins: VIW on cold external walls and VIC/VIHC on single or early double glazing, especially in listed buildings where replacement is blocked.

- Capital projects: DVIP on façades needing an A1 option with a clean, durable finish.

- Outcome: lower U-values without floor loss, warmer surfaces, better EPC.

Germany

Strong codes for new build; legacy stock still leaks.

- Quick wins: VIW for north-facing rooms and reveals; VIC for large panes in flats.

- Capital projects: DVIP when façades need both fire performance and a new face.

- Outcome: lower seasonal demand and better comfort at the same set-point.

Italy

Mixed climates; many older buildings with internal retrofit constraints.

- Quick wins: VIW and VIC to avoid external scaffolding; VIP cassettes in reveals.

- Capital projects: DVIP in coastal or high-sun regions where weatherable finishes matter.

Saudi Arabia, UAE, Qatar, Kuwait, Bahrain, Oman

High glass area, long cooling seasons; a large share of stock lacks meaningful insulation.

- Quick wins: VIC to cut night-time and weekend cooling losses; VIHC for zoned evening warmth in offices and homes that overcool.

- Capital projects: DVIP to raise façade performance with A1 options; VIP liners in ducts, doors and equipment housings to trim HVAC load.

- Logistics: VIBB to stabilise medical and fresh food routes without power or ice.

- Outcome: lower peak demand, fewer compressor hours, quieter, more stable interiors.

Matching problems to solutions

- Thin, high-performance insulation where space is tight: Flexible VIPs.

- External façade upgrade with A1 fire-class options and a designer finish: DVIP.

- DIY internal wall upgrade in hours: VIW.

- Window line without window works: VIC; add VIHC when zoned heat helps comfort.

- Cold chain without plugs or gel packs: VIBB Medical Box, Deep Cold Box, Rolling Cart Cover, Fresh Bag.

A decision framework your board can live with

Physics lens: reduce U × Area × ΔT × time at the worst surfaces first—usually glazing lines and the thinnest external walls.

Finance lens: compare avoided peak kW, reduced run hours and maintenance deferral alongside energy kWh; include comfort value that retains tenants and guests.

Operations lens: target works with no scaffolding and minimal downtime; favour DIY-deployable options to spread action quickly.

Compliance lens: align with EPC, fire class and heritage constraints from the outset; choose A1-capable façades where required.

Human lens: aim for stable mean radiant temperature—that is what occupants feel; it often permits lower thermostat settings without complaint.

Fresh application scenarios you can act on this quarter

- Bay windows and oriels: retrofit VIC with side returns to choke edge leakage; add VIW to adjacent returns for a continuous thermal line.

- Server-room doors and hot-aisle skins: fit VIP panels to thin doors and containment baffles; better separation means lower CRAH fan speeds.

- School exam halls: deploy VIC/VIHC during exam season to stabilise temperatures without whole-building set-point hikes.

- Hospital food service: VIBB Rolling Cart Covers to carry hot or cold meals between kitchen and wards without powered trolleys.

- Retail frontages: use DVIP where fire class is crucial; pair with VIC after hours to limit radiative losses through display glass.

- Transport cabins: VIP in headliners and bulkheads trims HVAC loads without stealing passenger space.

- Temporary clinics and pop-ups: VIW for fast cold-wall treatment; VIBB Medical Boxes to hold 2–8 °C locally without sockets.

A fair word on limits

- New builds with unconstrained depth may still use conventional thick insulation on cost grounds.

- High-impact zones need protective skins or cassettes for vacuum systems.

- Heavy fixings should bypass vacuum layers; we help detail this.

Honest constraints, addressed early, make projects smoother and outcomes better.

Where to begin—an action plan you can start this month

- Survey the leaks. Note rooms that feel cold or hot, big panes, draught paths, and refrigeration doors that stand open.

- Fix the worst first. Use VIW for cold walls and VIC/VIHC for glazing; you will feel the change by evening.

- Plan the façade. If you need new weathering and fire performance, design around DVIP.

- Detail the awkward bits. Use VIP shapes in reveals, returns, plant rooms, ductwork and doors.

- Stabilise your chain. Move critical routes to VIBB so goods arrive in band without power.

- Then scale generation. Once demand is down, your heat pump, PV and storage work less and cost less.

Addressing the usual objections—directly

“Won’t we trap moisture?”

Manage vapour with appropriate surface finishes and perimeter sealing; in most internal retrofits, raising the internal surface temperature reduces condensation risk rather than increasing it.

“Is vacuum tech too delicate?”

Treat it like any high-performance component. Use protective skins, cassettes and planned fix points; our systems are designed for handling in real buildings, not laboratories.

“What about embodied impact?”

Because vacuum insulation achieves performance at millimetre scale, it can reduce total material mass versus thick assemblies. Operational savings dominate the lifecycle in high-load climates.

“Will curtains make rooms too dark?”

Operate by day–night logic: open for daylight and solar gains; close for performance. Specify lighter decorative fabrics if evening brightness is a priority.

Ready to translate percentages into real savings?

- Contact our Customer Service Team for a free project assessment—share areas, photos and tariffs and we will sketch payback and U-value improvements.

- Prefer a direct conversation? Email or phone Professor Saim Memon to discuss design options for homes, campuses or portfolios.

- Download catalogues, specifications, videos and FAQs: www.sanyoulondon.com

Insulate first. Then electrify and generate. That is how we cut carbon, tame bills, and make buildings comfortable—today and for the next generation.

Share

Author

Prof. Dr. Saim Memon

PhD, CEng, FHEA, MSc, BEng(Hons), PGC-TQFE, GTCS, MCMI, MIET, MIEEE, MInstP, IBPSA, APCBEES, MPEC

CEO | Industrial Professor | Inventor | British Scientist | Chartered Engineer | Qualified Teacher | Chief Editor | World Speaker | Pioneer in Vacuum Insulation Energy Technologies