Thermal performance comparison of DVIP with conventional insulation materials

First principles—what we are comparing

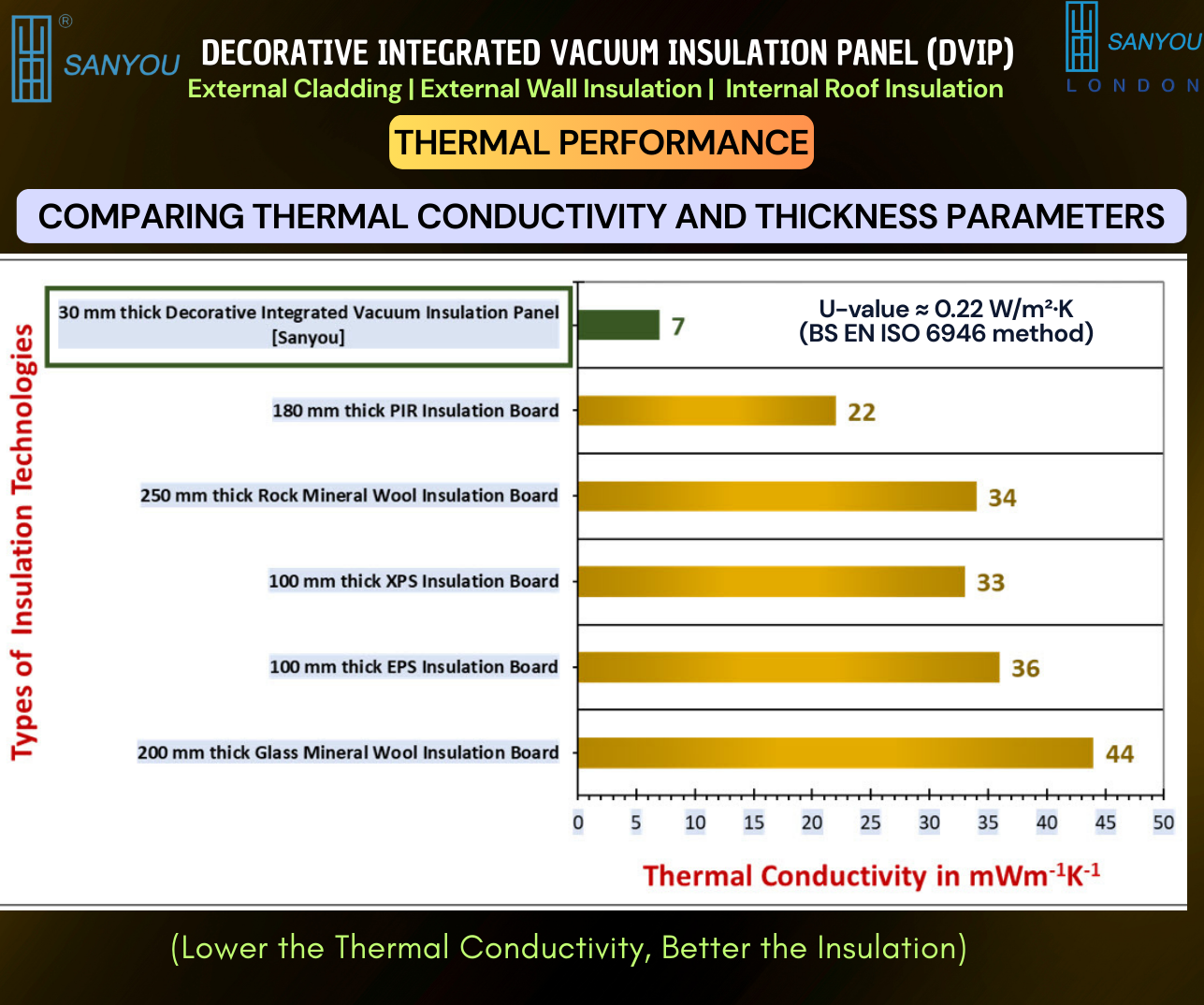

Two numbers matter for designers and decision-makers:

- Thermal conductivity (λ): material property in W/m·K; the lower it is, the better the insulator.

- U-value: heat flow through the whole layer or assembly in W/m²·K; again, lower is better.

Our (Sanyou London) 30 mm Decorative Integrated Vacuum Insulation Panel (DVIP) has λ ≈ 0.007 W/m·K and a design U ≈ 0.22 W/m²·K—achieved in a slim, factory-made panel that is also the exterior finish.

Thermal showdown—millimetres vs. centimetres

To make this useful on a drawing, here is the thickness conventional materials need to match DVIP’s U ≈ 0.22 W/m²·K (single-layer equivalence; films, fixings and substrates add small corrections):

| Insulation type | Declared λ (W/m·K) | Thickness to reach U≈0.22 W/m²·K |

|---|---|---|

| DVIP (Sanyou London) | 0.007 | 30 mm (given) |

| Rock mineral wool | 0.034 | ≈155 mm |

| Glass mineral wool | 0.044 | ≈200 mm |

| PIR board | 0.022 | ≈100 mm |

| EPS foam | 0.036 | ≈164 mm |

| XPS foam | 0.033 | ≈150 mm |

Result: one 3 cm DVIP tile achieves the same order of U-value that bulk products reach only at 10–20 cm. That frees net internal area, trims façade depth, and reduces bracket sizes and crane weight—without compromising performance.

Interpreting the “headline” λ values

- DVIP: λ ≈ 0.007 W/m·K at 30 mm → U ≈ 0.22 W/m²·K (design value).

- Rock mineral wool: λ ≈ 0.034 (even at 250 mm thickness, λ is still 0.034 because λ is a material property, not a thickness).

- Glass mineral wool: λ ≈ 0.044 (at 200 mm).

- PIR: λ ≈ 0.022 (at 180 mm).

- EPS/XPS: λ ≈ 0.036/0.033 (at 100 mm).

The takeaway is not that conventional insulation cannot reach low U-values; it can—if you add a lot of thickness. The point is efficiency per millimetre: DVIP delivers very low U in very little depth, with the decorative finish and fire class built in.

Why DVIP’s 30 mm can beat bulky stacks in real buildings

- Space economics: 150–200 mm inside a flat often costs several square metres of sellable or usable area across a floorplate. 30 mm preserves layouts and window proportions.

- Detailing and psi-values: bulky insulation struggles at slab edges, brackets and reveals. Thin, cut-to-shape DVIP returns reduce linear thermal bridges, improving the true heat-loss picture beyond centre-of-panel U.

- Programme certainty: one panel replaces multiple layers—fewer trades, fewer interfaces, fewer weather delays.

- Whole-life performance: vacuum cores with barrier skins and getter/desiccant keep λ very low for decades; there is no fibre slump or compression loss at fixings.

- Fire and finish in one: your DVIP configuration carries Class A1 façade options and architectural skins; you are not stacking a combustible insulant behind a separate fire sheet and then adding a finish.

Fair comparisons engineers appreciate

A) “Match DVIP’s U with bulk insulation—how thick?”

Already shown above: 100–200 mm for typical PIR and wools.

B) “Match a very thick mineral-wool target—what DVIP depth?”

If a project demands, say, U ≈ 0.14 W/m²·K (roughly a 250 mm rock-wool wall centre-of-panel), the equivalent DVIP thickness is ≈50 mm. We can supply custom thicknesses or twin-layer DVIP cassettes where codes or clients want ultra-low U with minimal build-up.

Operational meaning, not just maths

At a winter ΔT = 20 °C, a wall at U ≈ 0.22 leaks ≈4.4 W/m², where older uninsulated masonry might leak 30–70 W/m². Over a 50 m² elevation, that is 130–330 W less heat bleeding continuously—quieter plant, steadier surface temperatures, and a measurable drop in bills. In summer, the same resistance slows heat ingress, softening late-afternoon HVAC spikes.

Practical specification notes (to land the advantage on site)

- Declare the assembly U-value with substrates, rails and cavity; we provide U- and ψ-value sketches for tender.

- Use factory sizing: DVIP panels are cut to your façade grid, with reinforced edge zones for fixings; avoid site drilling through the vacuum core.

- Detail reveals and slab edges with pre-cut returns; this is where DVIP’s thinness removes bridges conventional layers cannot treat cleanly.

- Fire strategy: select the A1 configuration appropriate to your rails and cavity ventilation; document as an assembly.

- Durability: our accelerated ageing indicates ≥ 35 years before any modest thermal drift begins; panels are waterproof, freeze–thaw stable, anti-ageing.

When to choose DVIP over thick conventional layers

- Depth-constrained façades (balconies, parapets, planning set-outs, sightlines).

- Heritage and premium schemes where proportions and internal area are non-negotiable.

- Fast reclads and occupied retrofits where fewer trades reduce risk and time on the scaffold.

- Hot- and cold-edge elevations where treating psi-values makes the comfort difference.

Next steps—turn the comparison into your façade plan

- Contact our Customer Service Team for full spec sheets, BIM objects and payback calculators tailored to your wall build-ups.

- Prefer a direct conversation? Email or phone Professor Saim Memon for a free façade assessment and a thickness/weight/U-value strategy matched to your grid and brackets.

- Explore the range, videos, FAQs and purchasing process at www.sanyoulondon.com.

Bottom line: Side-by-side, our DVIP delivers target U-values in millimetres that foams and wools need centimetres for—saving space, weight and energy while simplifying construction.

Share

Author

Prof. Dr. Saim Memon

PhD, CEng, FHEA, MSc, BEng(Hons), PGC-TQFE, GTCS, MCMI, MIET, MIEEE, MInstP, IBPSA, APCBEES, MPEC

CEO | Industrial Professor | Inventor | British Scientist | Chartered Engineer | Qualified Teacher | Chief Editor | World Speaker | Pioneer in Vacuum Insulation Energy Technologies