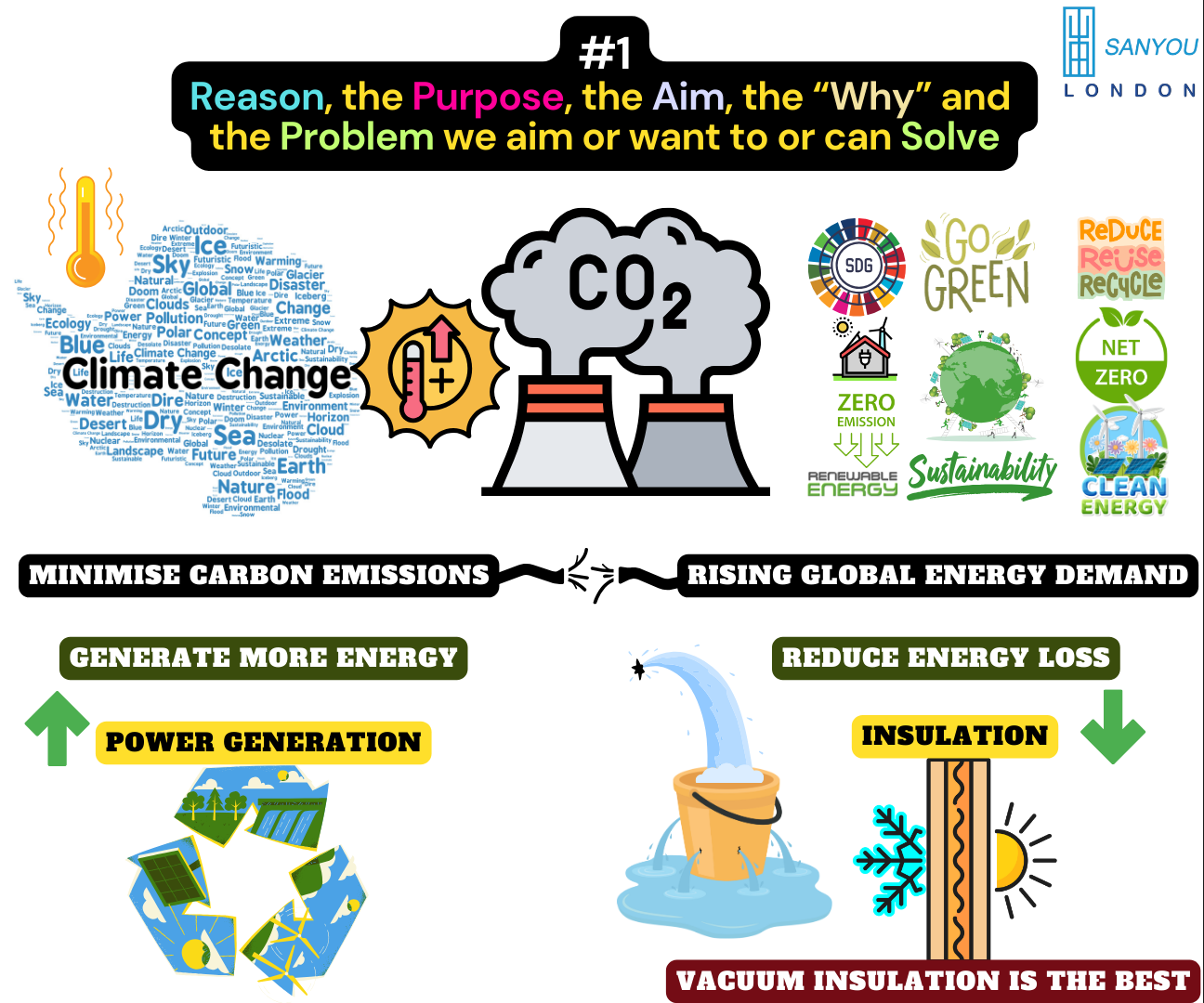

How climate change and carbon emissions link to power generation—and why vacuum insulation fixes the part we keep ignoring

Let’s keep this human. We can argue about slogans—Go green, Net Zero, Minus Zero, Low Carbon—but none of them change the arithmetic. Climate change is driven by greenhouse gases; energy use is the largest source; and buildings, vehicles and equipment waste a lot of that energy as heat. If we don’t close the “leaky bucket”, generation—renewable or otherwise—must work ever harder just to stand still.

The bucket with holes: a simple truth

Imagine a bucket with holes. You can keep pouring in more water, but if the holes remain, you never get ahead. The water is energy (kWh). The holes are losses through walls, roofs, glazing, doors, ducts, cold-store doors, vehicle shells and packaging. You can build bigger power stations or add more solar, but if the envelope keeps leaking, you chase your tail.

Balance happens when we:

- Reduce loss at the point of use (insulation and airtightness);

- Use efficient devices (heat pumps, variable-speed drives, efficient HVAC);

- Electrify what we sensibly can; and

- Generate clean power to cover what’s left.

Do them in the wrong order—generate first, fix losses later—and you lock in bigger, costlier supply.

Why insulation is the fastest lever

Every hour your building leaks heat (or your cold chain admits heat), you pay twice: first for the energy; then for the over-sized systems meant to compensate. Insulation reduces demand at source, so every future kWh of clean generation goes further. Engineers call this a negawatt: the cheapest, cleanest unit is the one you never had to produce.

Why vacuum insulation is different

All insulation slows heat transfer by three paths: conduction, convection and radiation.

- Vacuum removes the air, suppressing gas conduction and convection in the core.

- Low-emissivity barriers reduce radiative transfer.

- A porous solid framework (e.g. fibrous glass or fumed silica) minimises solid conduction.

Result: very low thermal conductivity at very small thickness. In our programme:

- Flexible VIPs: λ ≈ 0.0025 W·m⁻¹·K⁻¹ (ultra-low).

- DVIP façades (≈30 mm decorative panel): λ < 0.007 W·m⁻¹·K⁻¹ (lab data).

- VIW (≈4 mm DIY wallpaper): λ < 0.005 W·m⁻¹·K⁻¹.

- VIC curtain assembly: U = 1.87 W·m⁻²·K⁻¹; λ ≈ 0.013 W·m⁻¹·K⁻¹ for the vacuum layer.

Compare that to many common foams or wools and you see why vacuum insulation can hit tight U-value targets without thick build-ups—a decisive advantage in retrofits, heritage settings and constrained plant rooms.

The physics you can feel (without the jargon)

Heat loss through a surface is roughly Q = U × A × ΔT. Lower U and you cut Q (the heat you must supply) in direct proportion.

- Walls: Adding VIW to a cold external wall can shift a single-brick “problem wall” to a far better composite U-value, with comfort you notice in the first evening.

- Windows: Drawing a VIC at night reduces radiant chill from large panes and curbs convective downdraughts. You feel less “cold sink” near the glass even at the same thermostat set-point.

- Façades: DVIP delivers deep U-value cuts in slim profiles with A1 fire-rated configurations, so architects don’t have to trade safety for performance.

- Cold chain: VIBB units resist heat ingress so well that many routes can run without ice or power, avoiding weight, complexity and spoilage risk.

Carbon lens: Grid carbon intensity varies by country and hour, but every kWh not used is CO₂ avoided—immediately. Save demand first; then your solar, heat pump or battery doesn’t have to work as hard.

Real-world arguments you can take to a boardroom (or a kitchen table)

1) “We can’t afford big retrofits.”

You can’t afford ongoing losses either. DIY options—VIW for walls, VIC/VIHC for windows—start room by room. They are portable for renters and heritage-safe where glazing replacement is blocked.

2) “We don’t have the space for thick insulation.”

That’s the point. Vacuum insulation achieves high R-values in millimetres, not inches. You keep floor area, door reveals and services intact.

3) “Fire performance comes first.”

Agreed. DVIP offers A1 fire-rated configurations with a decorative, weatherable face—insulation and façade in one scope.

4) “We need results this quarter, not in two years.”

Curtains and wallpaper install like… curtains and wallpaper. No scaffolding; minimal downtime. VIBB rolls out across fleets immediately.

5) “What about cost and durability?”

Vacuum systems need sensible protection and detailing—which we provide. Use cassettes, protective skins, and planned joint layouts. Maintenance becomes routine; performance remains high.

Where the holes are—in more places than you think

Beyond obvious walls and windows, vacuum insulation solves awkward, high-leak spots:

- Window reveals and bay returns: thin VIW patches the weak links conventional boards can’t reach.

- Plant rooms and risers: VIP jackets or panels tame hot spots with minimal encroachment.

- Data-centre doors and containment skins: VIP improves aisle segregation without thick walls.

- Hospitality service routes: VIBB Rolling Cart Covers keep food in band from kitchen to ballroom.

- EV and battery thermal: VIP inserts stabilise pack temperatures and reduce HVAC load, helping range and cell longevity.

- Temporary clinics and outreach: VIBB Medical Boxes hold 2–8 °C for days in moderate ambients—no socket hunting.

- Heritage interiors: VIC/VIHC deliver comfort at the glazing line without touching protected windows.

A fair comparison: when not to use vacuum insulation

Honest engineering builds trust.

- Large, unconstrained new-build walls/roofs: conventional thick insulation may be the most economical where depth isn’t a problem.

- High-impact zones without protection: specify cassettes or durable outer skins—or choose a robust non-vacuum solution if puncture risk is extreme.

- Heavy fixings through the layer: coordinate fix points to bypass the vacuum core; if you can’t, use vacuum where continuous and conventional elsewhere.

Your action plan—insulate before you generate

- Survey the leaks: identify cold walls, big panes, draught paths, and refrigeration losses.

- Start thin: apply VIW to the coldest walls; install VIC where glazing dominates; choose DVIP if the façade needs both safety and a new face.

- Fix the awkward bits: reveals, returns, ducts—VIP shapes go where boards won’t.

- Stabilise the chain: shift critical routes to VIBB so goods arrive in band without powered boxes.

- Then electrify and generate: once demand drops, your heat pump, PV and storage can be smaller, cheaper and greener per kWh delivered.

Frequently asked questions

Does vacuum insulation really beat thick conventional layers?

Per millimetre, yes. Vacuum’s λ values are an order of magnitude lower than many common insulants, so thin assemblies meet targets where space is tight.

Isn’t it fragile?

Treat it like a high-performance component. DVIP and VIC/VIW incorporate protection by design; VIP cassettes and smart detailing manage edges and fixings.

What does this mean in carbon?

Every kWh avoided is CO₂ avoided. Whether your grid is clean or not, demand reduction improves economics and resilience immediately.

Will this help comfort, not just bills?

Yes. Reducing radiant asymmetry at glazing and raising internal surface temperatures feels warmer at the same thermostat setting.

Where our solutions fit

- Flexible VIPs: façades, reveals, HVAC, doors, vehicles, EV packs, data-centre racks.

- DVIP: A1 decorative cladding at ≈30 mm—insulation plus façade.

- VIW: 4 mm DIY wall upgrade; decorate and insulate in one.

- VIC: curtain with vacuum core; U = 1.87 W·m⁻²·K⁻¹, no window works.

- VIHC (2025): adds gentle radiant warmth at ≈1 kWh for 3 h.

- VIBB: temperature-holding bags and boxes; medical to fresh food, no power, no ice.

Ready to turn slogans into savings?

- Contact our Customer Service Team for a free project assessment—share photos, areas and tariffs for a quick U-value or payback sketch.

- Prefer a direct conversation? Email or phone Professor Saim Memon to discuss specifications, drawings and procurement.

- Explore catalogues, specifications, purchasing steps, videos and FAQs at www.sanyoulondon.com.

Insulate first. Then electrify and generate. That is how we turn climate ambition into outcomes you can measure—on a bill, on a meter, and in a warmer, more efficient room.

Share

Author

Prof. Dr. Saim Memon

PhD, CEng, FHEA, MSc, BEng(Hons), PGC-TQFE, GTCS, MCMI, MIET, MIEEE, MInstP, IBPSA, APCBEES, MPEC

CEO | Industrial Professor | Inventor | British Scientist | Chartered Engineer | Qualified Teacher | Chief Editor | World Speaker | Pioneer in Vacuum Insulation Energy Technologies