Vacuum Insulation Panels (VIP): Flexible Designs Making Real-World Energy Savings Possible in Buildings, Transport, EVs, and Electronics

I want you to see not just what we make, but why we make it—and how it helps you cut energy use in the real world.

What problem are we actually solving?

We all hear the terms climate change, sustainability, carbon footprints, global warming, and energy efficiency. In practice, too many good ideas stall in papers, studies, or policy notes. My team and I set a different goal: turn decades of research and hands-on engineering into practical products that save energy you can measure—in homes, hospitals, factories, vehicles, and the cold chain.

Why Vacuum Insulation Panels?

Short answer: VIPs offer exceptionally low thermal conductivity, so heat loss (or cooling loss) drops dramatically wherever they’re used.

In our portfolio, we’ve demonstrated λ-values as low as ≈2.5 mW/m·K for fibreglass-based cores at 15 mm, around ≈4.5 mW/m·K for fumed-silica cores at 25 mm, and ≈5 mW/m·K at just 4 mm in our Vacuum Insulated Wallpaper (VIW) line—evidence that ultra-thin formats can still deliver serious insulation.

What about the real-world effect? Lower conductivity means higher resistance to heat flow at the same thickness. That lets you:

- Achieve the same insulation with far less space, or

- Get far better insulation in the space you already have.

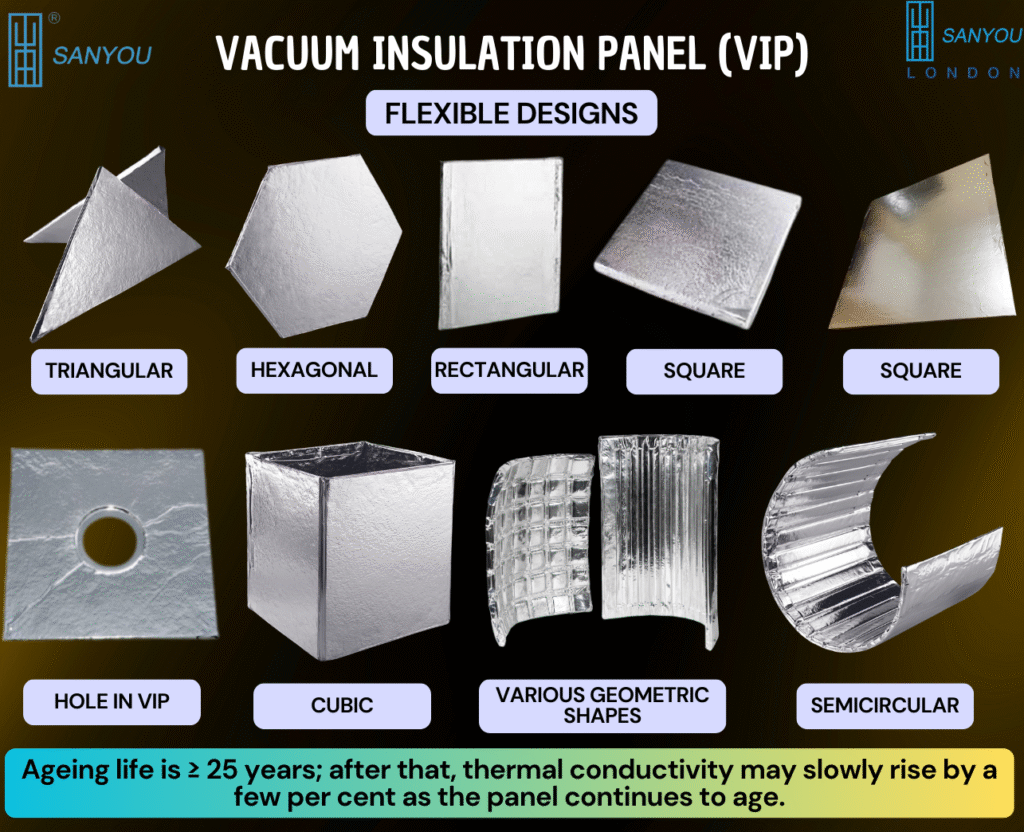

What do we mean by “Flexible Design”?

Rigid boards struggle in tight or complex spaces. Our flexible VIP design options—including custom shapes, notches, and precision cut-outs/holes—let you insulate where it matters most: corners, service zones, curved forms, and awkward voids. You get insulation without compromise, rather than redesigning your product or building to suit a standard board.

Good engineering note: VIPs are sensitive to puncture. We use appropriate protective layers and outer skins, and we design with installers in mind so panels are safeguarded in service.

Where do flexible VIPs make the biggest difference?

🏗️ Construction & Retrofitting

- Applications: cavity walls, internal lining, external wall insulation, lofts/roofs, reveals, and slender retrofits where space is at a premium.

- Why VIPs: ultra-thin build-ups with high performance, ideal for heritage constraints or premium floor-area retention.

- Fire safety: A-class fire-rated options are available, giving you peace of mind where many thermoplastics (EPS, XPS, PU foams) are flammable.

- Global relevance: from elegant homes in Saudi Arabia and the UAE to modern sustainable builds across the UK, Europe, and China—VIPs help cut electricity bills and support net-zero goals.

🚗 Electric Vehicles (EVs)

- Cabin: reduce HVAC loads for longer range and quieter comfort.

- Battery systems: help maintain safer, more stable pack temperatures, supporting performance and longevity—especially in hot or fast-cycling duty cycles.

🚛 Transport & Cold Chain Logistics

- Trucks, caravans, containers: more insulation in the same wall thickness means smaller compressors, lower fuel/electric draw, and tighter temperature control.

- Outcome: fewer temperature excursions, better product integrity, and lower operating cost per route.

❄️ Refrigeration & Cooling Appliances

- Refrigerators/freezers, vending, medical storage: keep the cold in and compressor cycling down.

- Knock-on benefits: reduced energy use and, in many designs, more usable internal volume for the same external dimensions.

💻 Electronics, Automation & AI Hardware

- High-density systems run hot. VIPs help guide and isolate heat paths, stabilise operating temperatures, and protect thermally sensitive components—supporting performance and service life.

How do VIPs compare with common insulation?

- Thickness efficiency: VIPs reach high R-values in a fraction of the thickness of mineral wool or plastic foams.

- Fire performance: non-combustible, A-class options stand apart from many polymeric foams.

- Durability: designed correctly with protective skins and detailing, VIPs maintain performance where conventional materials would need far more space.

What about shapes, sizes, and build options?

- Shapes: rectangles, tapers, arcs/curves, and complex profiles with engineered cut-outs/holes for services and fixings.

- Thicknesses: from ultra-thin (≈4 mm) applications to medium and higher gauges where structure or handling requires it.

- Outer skins: specified to suit the application—impact-resistant laminates, fire-optimised finishes, or hygienic surfaces for food/medical contexts.

Are there design and installation best practices?

Yes—these three keep projects smooth:

- Design in the protection. Treat VIPs like high-performance components. Use protective layers or cassettes, and coordinate fixings so nothing pierces the panel.

- Detail the edges. Account for transitions, joints, and service penetrations early; flexible formats make this easier.

- Specify by performance. Work to λ-targets, U-value goals, fire class, and service environment (temperature, humidity, cleaning chemicals), then select the VIP stack accordingly.

What measurable outcomes should you expect?

- Lower energy use for heating, cooling, or refrigeration.

- Space savings without sacrificing performance—often freeing up volume or preserving floor area.

- Operational resilience, with tighter temperature control in EV packs, cold chain assets, and electronics.

Why this matters now

Straightforward, robust insulation that fits the real geometry of buildings, vehicles, and devices is exactly the kind of practical innovation we need. Flexible VIPs unlock that fit—so you can capture the performance on paper and on the meter.

Ready to specify—or want a quick chat?

- Speak to our Customer Service Team or Professor Saim Memon to discuss your project, drawings, targets, and constraints.

- Ask for samples, thickness guidance, CAD support, and budgetary pricing.

- Explore products, specs, purchasing options, videos, and FAQs: www.sanyoulondon.com

Let’s design insulation that adapts, performs, and helps you move confidently towards a net-zero future.

Share

Author

Prof. Dr. Saim Memon

PhD, CEng, FHEA, MSc, BEng(Hons), PGC-TQFE, GTCS, MCMI, MIET, MIEEE, MInstP, IBPSA, APCBEES, MPEC

CEO | Industrial Professor | Inventor | British Scientist | Chartered Engineer | Qualified Teacher | Chief Editor | World Speaker | Pioneer in Vacuum Insulation Energy Technologies