Energy, Thermal and Sound Insulation Performance Analysis of the Decorative Integrated Vacuum Insulation Panel (DVIP)

Why we ran this experiment

Claims are easy; evidence is better. To isolate the contribution of the decorative integrated vacuum insulation panel, we constructed two test houses of identical geometry in our plant area. Each has a 5 m × 4 m floor plate, identical orientation, door and window openings, and matching airtightness targets.

- House A: clad and lined with MCM Decorative Integrated VIP (DVIP (Sanyou London)).

- House B: clad and lined with homogeneous, non-vacuum panels of the same thickness and comparable finish.

We then ran three controlled trials: energy consumption, rewarming (heat-soak) response, and sound insulation.

Test design at a glance

Set-up and controls

- Same footprint, height, and envelope area; same glazing specification and shading.

- Identical HVAC units, thermostats, diffusers and control logic.

- Matched internal loads during tests (dummy loads for people, lighting and small appliances where relevant).

- Calibrated plug-in power meters for HVAC energy; class-rated temperature loggers at multiple points; a sound level meter logging A-weighted noise in real time.

- Doors and windows kept closed during energy and rewarming trials; sound tests performed with standardised source levels outside the structure.

- Data logged at one-minute intervals; results checked for sensor drift and obvious outliers.

Headline results

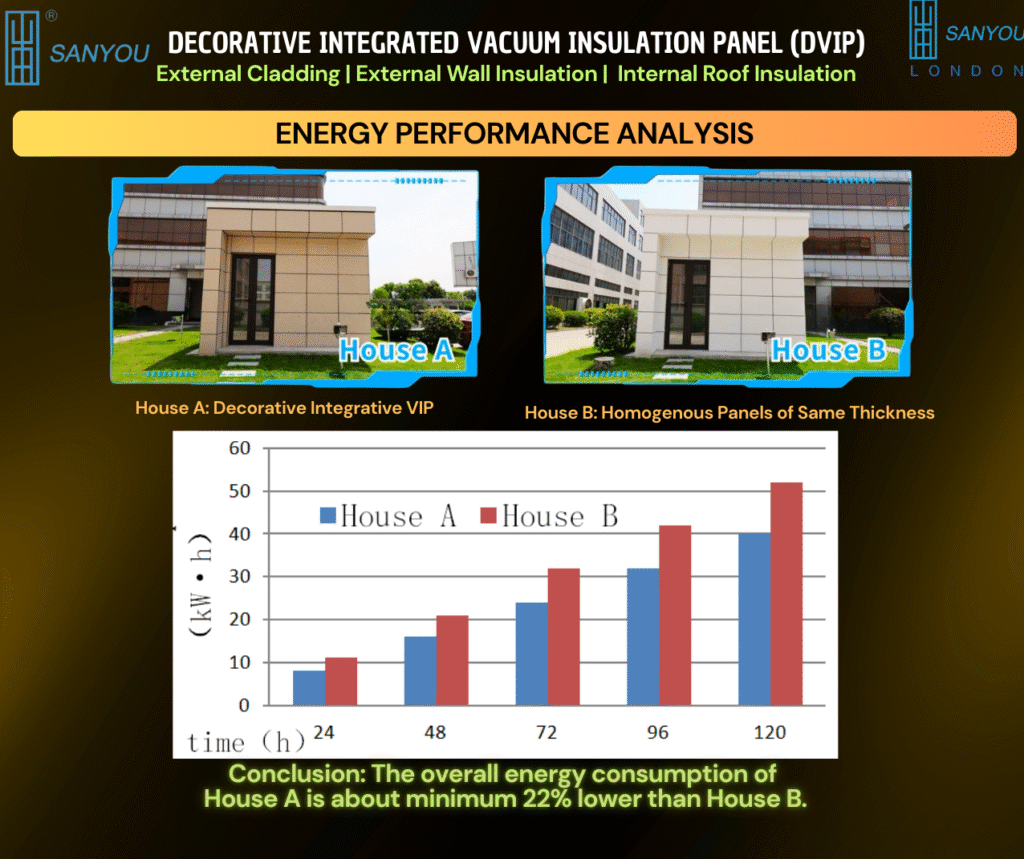

- Energy consumption (air-conditioning): House A ran about 22% lower total electrical energy than House B over the same duty profile.

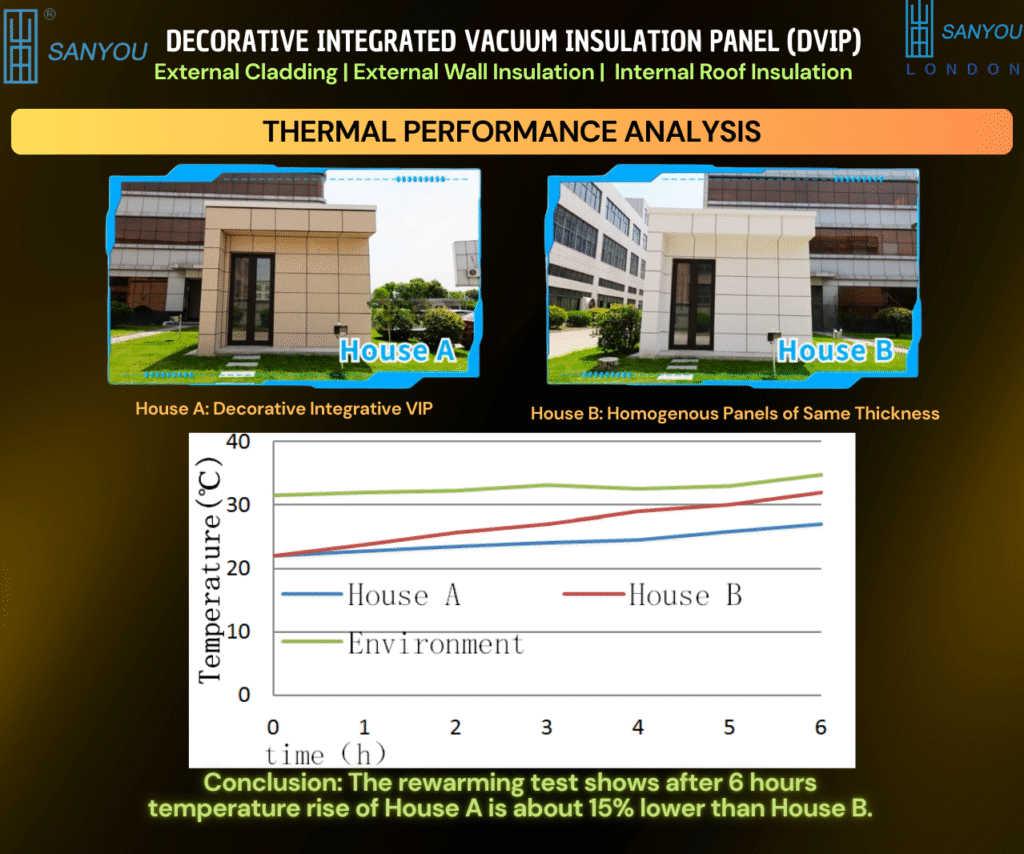

- Rewarming (heat-soak) test: after switching off cooling and holding both internal loads equal, the six-hour temperature rise in House A was about 15% lower than House B.

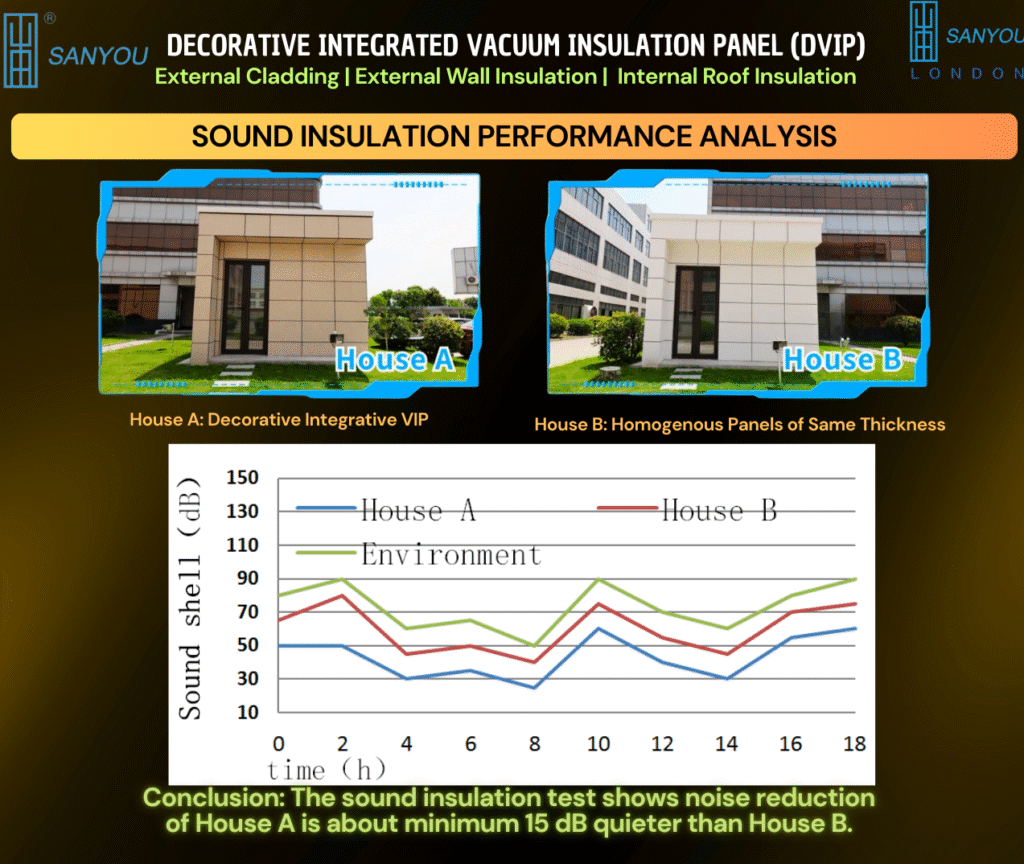

- Sound insulation: with a controlled broadband source outside, House A measured at least 15 dB quieter inside than House B.

These figures were repeatable across test windows and remained robust after removing outlier minutes caused by short, unavoidable access events.

What the numbers mean in practice

1) Energy consumption

A roughly one-fifth reduction in cooling energy is not a marginal gain; it is the difference between plant idling comfortably and labouring in hot spells. For building owners this translates into:

- Lower electricity bills through the peak season.

- Calmer indoor temperatures with fewer hard compressor restarts.

- Longer service life for HVAC components due to reduced run hours and gentler cycling.

2) Rewarming (heat-soak) behaviour

The 15% slower temperature rise demonstrates that DVIP dampens heat ingress when cooling is off—during demand-response events, grid dips, or scheduled maintenance. The benefit is more time in the comfort zone and less “catch-up” energy when systems restart.

3) Sound insulation

A 15 dB interior noise reduction is very noticeable to occupants—speech intelligibility improves, and background noise feels calmer. For locations near roads, rail or busy courtyards, this is the difference between “acceptable with windows closed” and “genuinely quiet”.

Why DVIP changes the outcome

DVIP (Sanyou London) combines a vacuum-insulated core with decorative exterior skins in a single, factory-made board. Removing the bulk of the air in the core suppresses gas-borne heat transfer; low-emissivity internal barriers reduce radiative exchange; the microporous scaffold keeps solid conduction low. The result is very high thermal resistance in only 30 mm, with a finished surface that resists weather, ageing and freeze–thaw cycles. The evacuated core also reduces airborne sound passing through the panel—hence the measured acoustic benefit.

Method detail (so you can copy the protocol)

Energy trial

- Pre-condition both houses to the same set-point; stabilise for ninety minutes.

- Run a twelve-hour schedule with identical set-points and internal loads.

- Log HVAC power draw and internal air temperatures at three heights (ankle, seated, head).

- Report total kWh and average set-point deviation.

Rewarming trial

- Cool both houses to the same starting temperature.

- Switch off HVAC and maintain closed-house conditions for six hours.

- Log the room-average temperature rise and the rate of change per hour.

Sound trial

- Place a calibrated broadband source outside each house in turn at the same distance.

- Log internal A-weighted levels at the centre point and two corners; report the minimum differential versus House B to be conservative.

Quality notes

- Airtightness checked with the same blower at the start of the campaign; values within tolerance.

- Sensors cross-checked against a reference thermometer and sound calibrator.

Implications for design and procurement

- Developers and design teams: you can specify thinner façades without sacrificing performance—reveals, handrails and balcony lines stay true to the architectural intent.

- Contractors: one panel replaces multiple layers, reducing interfaces and installation time; fewer trades, fewer snags.

- Facilities managers: expect lower peak HVAC loads, smoother recovery after interruptions, and a measurable drop in occupant noise complaints.

- Cost planners: energy savings, programme reductions, and preserved floor area create value beyond the headline material rate.

Where to deploy first

- Perimeter rooms with persistent comfort complaints or high solar exposure.

- Reclads where planning lines fix façade depth and bracket stand-off.

- Internal roof linings over cold spaces, where radiant chill and condensation risk persist.

- Noise-sensitive uses such as bedrooms, healthcare waiting areas, teaching rooms and hotel corridors.

Fair limitations and responsible next steps

- Results arise from controlled test houses. Real buildings have more variables—junctions, penetrations, and occupant behaviour. We address this by providing project-specific design notes, detailing for returns and edges, and site QA checklists to lock in the gains.

- Sound performance varies with flanking paths through floors, windows and doors; treat the façade as a system.

- For compliance, fire and weather ratings are documented at assembly level; we supply the evidence and installation method statements.

Summary for decision-makers

- Energy: about 22% less cooling electricity in our test house with DVIP (Sanyou London).

- Thermal stability: ~15% slower warm-up across six hours when systems are off.

- Acoustics: at least 15 dB quieter inside under controlled external noise.

These are practical, bankable improvements, delivered by a single 30 mm decorative panel rather than a stack of separate layers.

Ready to translate this into your project?

- Contact our Customer Service Team to request the full test brief, raw data snapshots, and a project-specific performance sketch for your elevations and roof bays.

- If you prefer a direct technical conversation, you are most welcome to email or phone Professor Saim Memon. We will review drawings, propose a detailing set, and provide tailored price quotations.

- Explore the full DVIP range, specifications, purchasing process, videos and FAQs at www.sanyoulondon.com.

Build beautifully; measure honestly. DVIP (Sanyou London) gives you both.

Share

Author

Prof. Dr. Saim Memon

PhD, CEng, FHEA, MSc, BEng(Hons), PGC-TQFE, GTCS, MCMI, MIET, MIEEE, MInstP, IBPSA, APCBEES, MPEC

CEO | Industrial Professor | Inventor | British Scientist | Chartered Engineer | Qualified Teacher | Chief Editor | World Speaker | Pioneer in Vacuum Insulation Energy Technologies