We build with concrete and brick for centuries—so the fabric we choose must serve future generations

The United Kingdom is full of long-lived buildings: terraces, townhouses, mills, churches, and post-war blocks. Many are beautiful, and many are expensive to heat. When pensions replace salaries, the envelope still leaks, and the bill still arrives. If we want homes that are warm and affordable in twenty, fifty, or a hundred years, we must address heat loss at the materials level—concretely, with the numbers.

First principles in plain English

Thermal conductivity (k) tells you how easily heat moves through a material. Lower is better.

U-value tells you how much heat crosses a finished element—wall, roof, or window—per square metre for each degree of temperature difference. Again, lower is better.

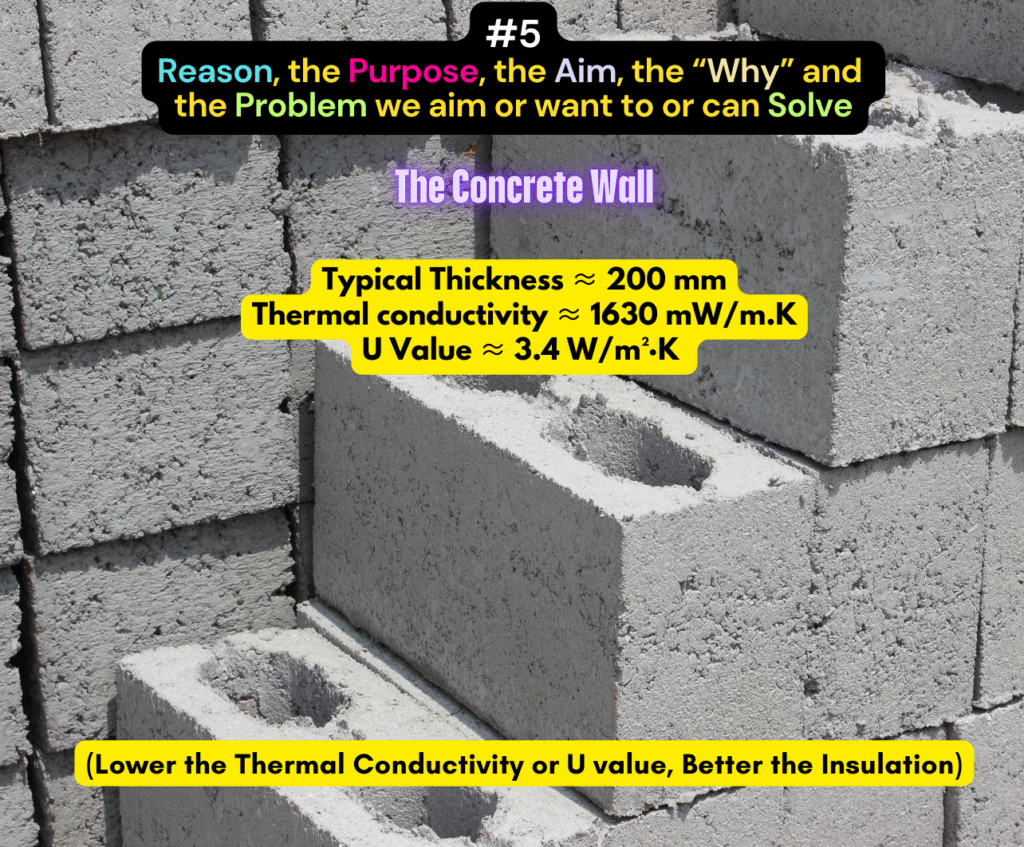

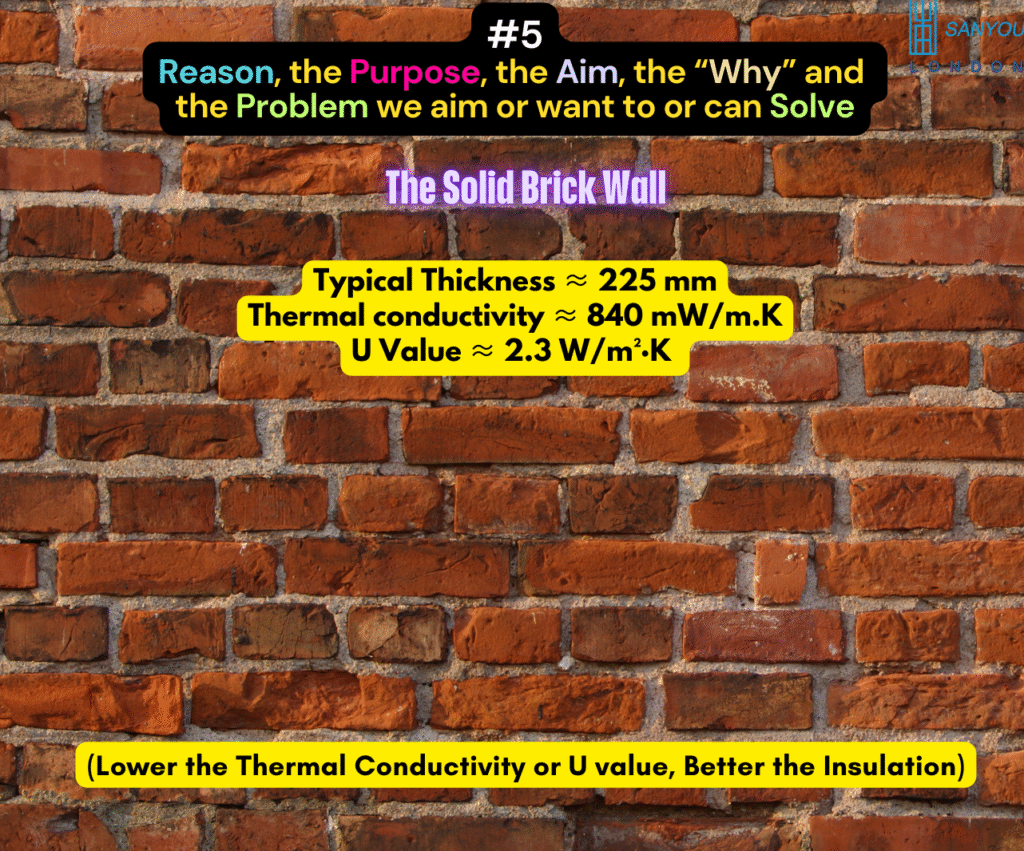

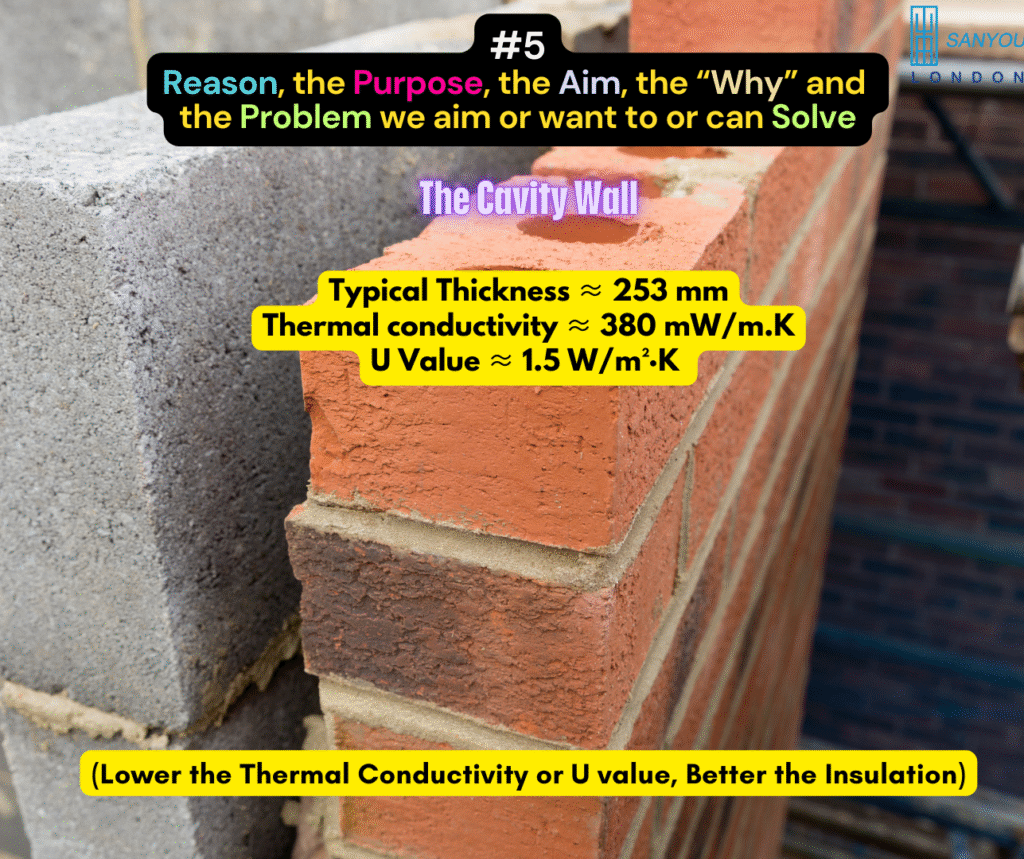

Your examples describe uninsulated wall types (conductivity in mW·m⁻¹·K⁻¹; U-values in W·m⁻²·K⁻¹):

- Cast concrete wall — k ≈ 1,630 mW·m⁻¹·K⁻¹ (1.63 W·m⁻¹·K⁻¹); U ≈ 3.4

- Solid brick wall — k ≈ 840 mW·m⁻¹·K⁻¹ (0.84 W·m⁻¹·K⁻¹); U ≈ 2.3

- Unfilled cavity wall — k (effective) ≈ 380 mW·m⁻¹·K⁻¹; U ≈ 1.5

All three lose heat fast in winter and admit heat fast in summer. That is why rooms feel cold beside external walls in January and stuffy beside sun-struck façades in July.

What these numbers mean in a room you can stand in

People do not feel U-values; they feel surface temperature and radiant balance.

Take a typical winter case: indoors 20 °C, outdoors 0 °C (ΔT = 20 K). Using standard internal film resistance, the approximate internal surface temperatures for your three uninsulated walls are:

- Concrete wall (U ≈ 3.4): surface roughly 11–12 °C

- Solid brick (U ≈ 2.3): surface roughly 14 °C

- Unfilled cavity (U ≈ 1.5): surface roughly 16 °C

Why it matters:

- Below about 13–14 °C, occupants report radiant chill even if the air is 20 °C.

- Cooler surfaces raise condensation and mould risk in corners and behind furniture.

- Radiators and heat pumps have to work harder to hold set-point because the envelope is simply bleeding heat.

How a thin vacuum layer changes the calculation

A vacuum-insulated lining has an exceptionally low conductivity at very small thickness. Using an illustrative 4 mm vacuum-insulated wallpaper layer (k < 5 mW·m⁻¹·K⁻¹), the added thermal resistance is about 0.8 m²K/W—that is a lot for 4 mm.

Apply that lining internally to each wall type:

- Concrete wall: new U ≈ 0.9 (from 3.4) → winter surface ≈ 17–18 °C

- Solid brick: new U ≈ 0.8–0.9 (from 2.3) → winter surface ≈ 18 °C

- Unfilled cavity: new U ≈ 0.7–0.75 (from 1.5) → winter surface ≈ 18 °C

Three outcomes follow immediately:

- Comfort rises: mean radiant temperature steps closer to the air temperature; rooms feel “even” instead of “cold at the edge”.

- Heating input falls: with U roughly cut by two to four times (case-dependent), heat flow drops in direct proportion.

- Moisture risk eases: warmer internal surfaces reduce the chance of condensation at cold corners and behind wardrobes.

In summer, the same layer slows inward heat flow. Peak afternoon temperatures climb more slowly, giving HVAC plant longer off-cycles and fewer hard restarts after short outages.

Beyond a single layer—what a thin façade system can do

Where planning and appearance allow, a thin decorative façade panel with a vacuum core adds far more resistance in a small depth (e.g., ~30 mm panel thickness). Two advantages for constrained streets and reveals:

- Low U-values without fattening the wall line, so you protect internal area and window proportions.

- A finished exterior face with durability and fire classification designed into the same element.

Pair an external thin façade with an internal vacuum lining on problem elevations and you gain:

- Stable internal surface temperatures in winter

- Slower heat ingress in summer

- Lower plant sizing and fewer complaints to the managing agent

Practical realities—what to plan for on site

- Continuity at edges matters. If a lining stops short at skirting, head, or returns, heat will bridge the gap. Plan neat returns around reveals and sockets.

- Services and fixings. Route cables and mount shelves with dedicated fix lines that bypass the vacuum layer; it is routine once set out.

- Moisture. Fix any damp first. The aim is a dry substrate; then the warmer surface created by the lining lowers risk, not raises it.

- Heritage interiors. Where external works are not permitted, internal vacuum linings and window-line treatments are reversible and minimally invasive.

What about windows in these heavy-wall buildings?

Even after you treat the wall, glazing dominates many rooms. A vacuum-insulated curtain drawn at night or during peak sun throttles both radiant and convective losses at the glass line. The result is immediate:

- Less “cold sink” beside panes in winter evenings

- Slower heat gains in summer afternoons, especially on west elevations

- Quieter HVAC because the plant does not have to chase spikes

Where evening cosiness matters, a low-power heatable variant adds a gentle radiant lift for pennies per hour while the vacuum layer keeps losses down.

A short calculation homeowners can check themselves

Pick one cold outside wall in a bedroom. In winter, if the wall is uninsulated and U ≈ 2.3, the heat flow at ΔT = 20 K is about 46 W per square metre. Line the same area to U ≈ 0.85, and the flow drops to about 17 W per square metre. Over a 10 m² wall, that is ≈ 290 W less heat leaving whenever the room is at temperature. Devices cycle less, and the room feels calm rather than “hungry”.

Why this is the fairest route during a cost-of-living crisis

- You do not need to thicken the room. Millimetres, not inches.

- You avoid months of disruption. Internal linings and window-line treatments go in with light tools and tidy finishes.

- You help the future owner. Lower running costs and warmer surfaces tend to lift EPC results and support resale.

- You protect the grid. Reduced peaks mean fewer stress events during cold snaps or heat waves.

Where to begin—one weekend, one cold room

- Choose the worst room (north-facing bedroom or living room).

- Treat the cold wall with a vacuum-insulated lining; plan tidy returns at reveals.

- Add a window-line treatment for evenings.

- Measure before and after with a simple IR thermometer or thermal camera—surface temperatures tell the story better than any brochure.

Ready to specify—or want numbers for your building?

- Contact our Customer Service Team for guidance, samples, U-value sketches, and pricing tailored to your wall build-ups.

- Prefer a direct conversation? Email or phone Professor Saim Memon and we will walk through your drawings and plan a low-disruption sequence for heritage or occupied homes.

- Explore full product specifications, purchasing steps, videos, and FAQs at www.sanyoulondon.com.

Build for centuries; heat sensibly today. Thin vacuum insulation turns heavy walls from liabilities into assets—quietly, quickly, and with numbers that stand up.

Share

Author

Prof. Dr. Saim Memon

PhD, CEng, FHEA, MSc, BEng(Hons), PGC-TQFE, GTCS, MCMI, MIET, MIEEE, MInstP, IBPSA, APCBEES, MPEC

CEO | Industrial Professor | Inventor | British Scientist | Chartered Engineer | Qualified Teacher | Chief Editor | World Speaker | Pioneer in Vacuum Insulation Energy Technologies