Can Flexible Vacuum-Insulation Panels Boost EV Battery Life & Cabin Comfort?

Electric and hybrid vehicles fight two quiet battles every day: summer heat soak that pushes electronics and battery packs towards their limits, and winter chill that diverts precious energy into cabin heating. Thin, flexible Vacuum-Insulation Panels (VIPs) give engineers a new lever—serious thermal resistance in millimetres—to win both battles without heavy redesigns.

The simple physics—why VIPs help vehicles

VIPs suppress gas-borne conduction and convection inside the panel. In practice this means:

- Less external heat leaking in during hot soaks and peak sun.

- Less stored warmth leaking out after pre-conditioning in winter.

- More uniform battery temperatures because external swings are muted.

Unlike bulky foams or wools, VIPs deliver that performance in very small thickness, protecting interior space, sightlines and service clearances.

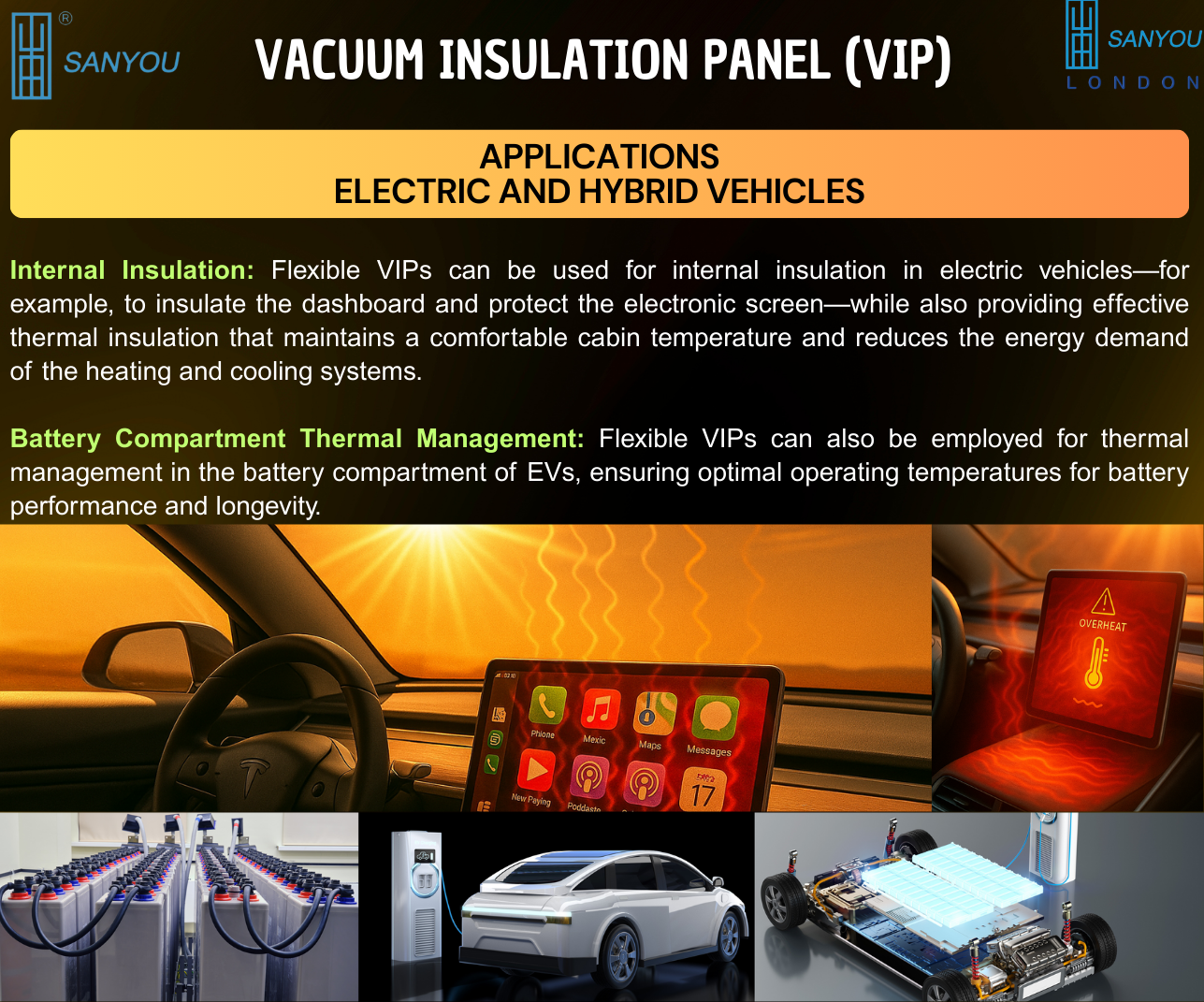

Where flexible VIPs go in EVs and hybrids

1) Dashboard, centre stack and glovebox surround

- Problem: solar load and engine-bay or inverter heat creep towards sensitive displays and compute modules.

- VIP benefit: a thin liner behind the fascia cuts radiant and conductive gains, helping prevent pixel fade, colour shift and processor throttling in hot soaks.

- Bonus: better passenger-airbag packaging because you keep the depth you already had.

2) Battery pack enclosure (top cover, side walls, service corridor)

- Problem: uneven cell temperatures increase resistance, unbalance modules and accelerate ageing; extreme events demand thermal containment should a cell vent.

- VIP benefit: a 3–5 mm VIP skin on the cold-facing or sun-facing sides helps smooth external swings, reduce pack heat gain in summer parking, and slow heat loss after winter pre-heat.

- Safety note: VIPs are not a fire barrier; they reduce thermal ingress/egress and can help slow propagation conditions when combined with the pack’s fire and venting design.

3) Floorpan, transmission tunnel, wheel-house liners

- Problem: road-surface heat in summer and underbody cold in winter push cabin loads up.

- VIP benefit: thin under-carpet or cassette-mounted VIPs cut the ΔT at the carpet, making cabins feel even at lower HVAC set-points.

4) Roof headliner, pillars and quarter panels

- Problem: high solar gains on roof and rear quarter lead to late-afternoon spikes.

- VIP benefit: discrete patches of VIP behind the headliner and trims reduce peak ingress without changing roof thickness or pillar trims.

5) Frunk, boot and thermal stowage

- Problem: groceries, medicines and electronics suffer in a hot frunk.

- VIP benefit: frunk liners or modular VIP totes maintain usable temperatures without power, extending usability and customer satisfaction.

What does this mean for range? A grounded example

Consider a compact EV on a hot urban day:

- Vehicle energy use (drive): ~18 kWh per 100 km

- HVAC draw in extreme heat: ~1.8–2.5 kW continuous in stop-go traffic

- Trip: 90 minutes

Energy into HVAC: 1.8–2.5 kW × 1.5 h = 2.7–3.75 kWh

If a targeted VIP package (dashboard, roof patches, door outers, floorpan hot spots) cuts the HVAC load by 25–35% in those conditions, that saves ~0.7–1.3 kWh.

At 18 kWh/100 km, that equates to ~4–7% extra range for the same charge. In harsher climates or long sun-soak plus drive cycles, total savings can approach ~10%, especially when paired with smart HVAC control and pre-conditioning. Results vary with vehicle, duty cycle and integration quality—but the magnitude is real.

Battery life: uniformity is everything

Cells dislike temperature spread. As a rule of thumb, every 10 °C rise accelerates certain ageing mechanisms. VIPs do not replace active thermal management; they reduce the workload by buffering the pack against sharp external swings and smoothing surface temperatures. The gains show up as:

- Fewer pack heating/cooling spikes in telemetry.

- Tighter ΔT across modules, supporting balanced ageing and stable range over life.

- Less parasitic energy used to hold set-points during parking and brief trips.

Lightweight by design

Because VIPs deliver performance in millimetres, the areal mass is modest. A typical 3–4 mm VIP adds only a small fraction of a kilogram per square metre (module-dependent). Strategic placement—rather than blanket coverage—keeps the mass delta negligible, preserves aerodynamics, and avoids packaging churn.

NVH and occupant comfort

The evacuated core reduces airborne sound transmission through treated panels. Combined with the thermal effect (warmer interior surfaces in winter; cooler in summer), occupants perceive a quieter, calmer cabin, often allowing lower fan speeds and gentler HVAC profiles.

Integration notes for automotive engineers

- Fixing and protection: mount VIPs in cassettes or behind trim; avoid direct fastener penetrations. Use adhesives compatible with the barrier film and interior temperatures.

- Crash and service: place modules outside load paths; maintain access to fasteners and fuse points. Design for field replaceability if a module is damaged.

- Thermal interfaces: pair VIPs with conductive pads or foils where heat must escape; do not trap hot components.

- Regulatory context: interior materials must satisfy flammability and emissions standards (e.g., FMVSS 302 or regional equivalents) and withstand vibration, salt, humidity and temperature cycling (e.g., ISO 16750-type environments). We supply automotive-grade skins and test plans to suit.

- EMC considerations: metallic barrier layers can influence EM field paths. Coordinate with antenna, NFC and keyless layouts; we adjust skin stacks accordingly.

Where to start—three fast wins

- Hot-soak pilot: instrument the dash cavity and display backplate on two otherwise identical cars. Add VIP behind the fascia in one, park both in peak sun, and compare temperatures and processor throttling events.

- Pack-edge buffer: add VIP to the top cover and sun-facing side of a mule pack; log ΔT across modules during soak-and-drive.

- Roof and floor patches: treat roof headliner above front seats and front footwells; measure HVAC duty and cabin cool-down time.

FAQs from programme managers

Will VIPs interfere with airbags or wiring?

We design no-go zones and clearance steps around inflators, looms and ducts; CAD integration is part of the package.

Can VIPs replace active thermal systems?

No. They reduce the burden on heat pumps, chillers and pack heaters, enabling softer control and lower energy use.

What happens if a module is punctured?

Modules are protected; if one is damaged, it is swapped like any trim component. We keep modules serialised for traceability.

Summary—what you gain with flexible VIPs

- Range stability in extremes by trimming HVAC energy.

- Electronics reliability by damping hot-soak spikes behind displays and compute.

- Battery life support by smoothing external swings and aiding temperature uniformity.

- Negligible packaging penalty thanks to millimetre-scale thickness and low mass.

Ready to evaluate VIPs on your platform?

- Contact our Customer Service Team for datasheets, CAD envelopes, sample kits and pilot test plans.

- Prefer a technical deep-dive? Email or phone Professor Saim Memon to review thermal models, placement options and validation metrics for your programme.

- Explore case studies, specifications, purchasing steps, videos and FAQs: www.sanyoulondon.com.

Thin layers, tangible gains—flexible VIPs bring measurable efficiency to cabins and battery enclosures without the bulk or fuss.

Share

Author

Prof. Dr. Saim Memon

PhD, CEng, FHEA, MSc, BEng(Hons), PGC-TQFE, GTCS, MCMI, MIET, MIEEE, MInstP, IBPSA, APCBEES, MPEC

CEO | Industrial Professor | Inventor | British Scientist | Chartered Engineer | Qualified Teacher | Chief Editor | World Speaker | Pioneer in Vacuum Insulation Energy Technologies