Can a 30 mm Decorative Vacuum Panel Replace Cladding & Insulation Layers?

Short answer: yes—when the panel is a Decorative Integrated Vacuum Insulation Panel (DVIP) engineered as a single, factory-made element that does the job of insulation board + vapour barrier + fire sheet + exterior finish.

What the DVIP actually is

- Thickness: 30 mm overall.

- Thermal conductivity (centre-of-panel): λ ≈ 0.007 W·m⁻¹·K⁻¹ (single-digit milliwatts per metre-Kelvin class).

- Finishes: Mid-Century Modern (MCM) textures or metal-type skins—colourfast, UV-stable.

- Fire: Class A1 façade configurations to BS EN 13501-1.

- Acoustics: 3-D sound absorption within the panel build, calming mid- to high-frequency noise on busy elevations.

- Durability: waterproof, freeze–thaw resistant, anti-ageing; accelerated ageing ≥ 35 years before any measurable thermal drift begins (after which λ may rise a few percent slowly).

- Form factor: made to any module—rectangles, curves, tapers, service cut-outs—so the façade grid drives the panel, not the other way round.

Inside the panel sits a vacuum-insulated core with getter/desiccant, encapsulated by a gas-tight barrier and protected by exterior-grade skins. The vacuum suppresses gas conduction and convection; low-emissivity layers curb radiation; the core minimises solid conduction. Hence the high R-value in millimetres.

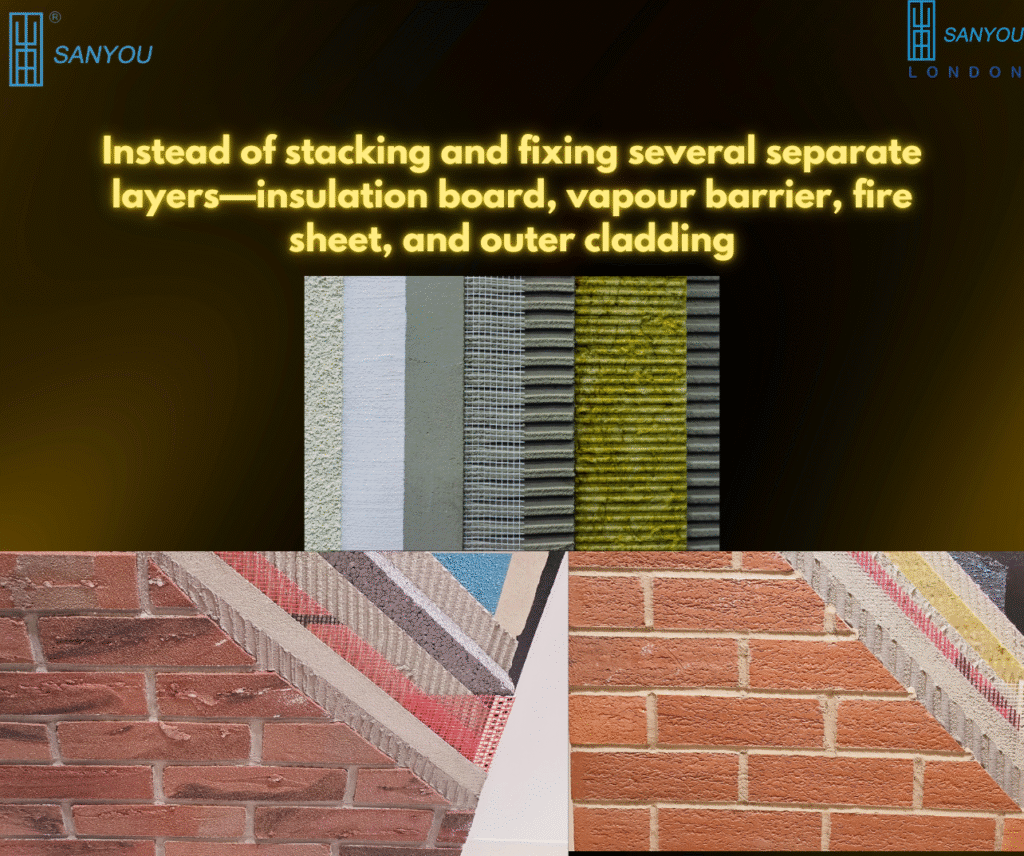

Side-by-side with the stack you already know

A conventional external wall build typically needs several layers:

- Mineral wool or PIR board (thick).

- Separate vapour or air-barrier layer.

- Fire protection board in certain zones.

- Sub-frame and rails.

- External finish (stone slip, metal cassette, tile).

DVIP compresses that into one panel that fixes to a sub-frame/rails. You keep a ventilated cavity as required by your façade strategy, but you remove trades and interfaces—and with them, many sources of error.

Programme effects you will feel:

- Fewer deliveries and fewer access lifts.

- Faster elevation coverage per day.

- Less rework at reveals and slab edges.

- Cleaner QA: one product, one set of tolerances.

What does 30 mm at λ 0.007 do to U-values? (Illustrative maths)

You can approximate the added thermal resistance R from DVIP as: RDVIP=0.0300.007≈4.29 m2 ⋅ K/WR_{\text{DVIP}} = \frac{0.030}{0.007} \approx 4.29\ \text{m}^2\!\cdot\!K/WRDVIP=0.0070.030≈4.29 m2⋅K/W

Add that to your existing wall’s resistance and invert to get U. Three quick examples:

- Cast concrete wall (≈ 200 mm, k ≈ 1.63):

Base R≈0.125R \approx 0.125R≈0.125; with surface films total R≈0.295R \approx 0.295R≈0.295 → U ≈ 3.39.

With 30 mm DVIP: total R≈4.58R \approx 4.58R≈4.58 → U ≈ 0.22 W·m⁻²·K⁻¹. - Solid brick wall (≈ 215 mm, k ≈ 0.84):

Base R≈0.256R \approx 0.256R≈0.256; with films R≈0.426R \approx 0.426R≈0.426 → U ≈ 2.35.

With DVIP: total R≈4.71R \approx 4.71R≈4.71 → U ≈ 0.21. - Basic cavity masonry (uninsulated):

Base UUU often > 1.5; with DVIP you can land near 0.20–0.25 without pushing the wall line out.

Translate that to operations: at a winter ΔT of 20 °C, a bare concrete wall leaks ~68 W/m²; with DVIP it’s ~4–5 W/m²—over 90% less transmission through the opaque zone.

Beyond U-values: junctions and bridges

Buildings rarely fail in the middle of a panel. They fail at edges. Because DVIP is thin and cut-to-shape, you can wrap performance into the places that leak most:

- Slab edges & bracket lines: narrow DVIP strips behind rails reduce psi-values without bulky thermal pads.

- Window heads, jambs and sills: pre-cut returns calm frame-adjacent cold lines and improve internal surface temperatures.

- Parapets & upstands: add resistance without raising heights and compromising flashings.

- Spandrels: shallow pockets become genuinely insulating, stabilising interior temperatures near mullions.

Result: tidier thermography, fewer condensation complaints, and quieter HVAC because you are not chasing edge losses.

Installation: two standard archetypes

1) Rainscreen cassette

- DVIP is encapsulated as a cassette; fix on conventional rails with concealed hooks/kerfs at edge zones outside the vacuum core.

- Maintain a ventilated cavity as per façade design.

- Joints gasketed or open-jointed with baffles to suit wind-driven rain exposure.

2) Direct-fix to prepared substrate (internal roof lining / sheltered elevations)

- Adhesive bed with no-penetration through the core; perimeter trims protect edges.

- Suitable where exterior weathering is handled by an outer layer, or for internal roof/soffit applications in cold spaces.

Key site notes

- Set the airtight/vapour control strategy at assembly level; the panel’s barrier skin supports vapour control, but junctions still need proper tapes and seals.

- Use our fixing maps; fasteners land in reinforced zones or frames, never through the vacuum area.

- Edge protection is non-negotiable on handling; modules are replaceable if damaged.

Fire, water, sound—whole-system answers

- Fire: specify the A1 DVIP configuration with the rail and cavity arrangement required for your project, then document the assembly.

- Water: skins and joints are fully waterproof; freeze–thaw cycles do not degrade the vacuum core.

- Acoustics: the evacuated core plus textured finishes absorb and block different parts of the spectrum; façade noise from traffic and rail is perceptibly reduced on treated elevations.

What changes for the developer, QS and contractor

Developer

- Depth saved: 30 mm panel vs multi-layer stacks—reveals, handrails and balconies keep their intended proportions.

- Weight managed: fewer heavy layers; crane time and bracket sizing stabilise.

QS

- Trades removed: fewer interfaces, fewer prelims, fewer weather delays; tender comparators are cleaner.

- Whole-life value: fewer penetrations and joints to fail; surfaces remain stable and cleanable for decades.

Contractor

- Speed: larger modules; one trade covers area that used to involve three.

- Quality: factory geometry; fewer on-site cuts; simple QA—panel ID, level, plumb, joint, seal.

Internal roof lining—why DVIP is logical there too

Cold roofs and undercrofts often suffer condensation and radiant chill. A 30 mm DVIP lining:

- Lifts internal surface temperature so dew-point risk drops.

- Allows continuous insulation across purlins without lowering headroom.

- Provides a clean, finished face with integrated acoustic benefit.

A fair word on limits

- Penetrations: do not drill through a DVIP. Plan services and fixings at edge zones or with pre-formed cut-outs.

- Impact zones: specify impact-resistant faces or sacrificial skirtings where trolleys or bikes hit.

- Compliance: treat the panel as part of a tested façade assembly; we supply the documentation path.

What to ask for in your spec

- Panel sizes, curvature and tolerances matched to your grid.

- λ value, panel R, and target assembly U including cavity strategy.

- Fire class of the full build-up and required details at openings.

- Edge protection, joint type (open/gasketed), and water management.

- Maintenance: cleaning regime, replaceable module policy.

Ready to replace the stack with a single intelligent panel?

- Contact our Customer Service Team for specs, BIM objects, CAD details and pricing tailored to your elevations and roof bays.

- Prefer a direct discussion? Email or phone Professor Saim Memon to review drawings and receive a free façade assessment with a thickness/weight/U-value plan.

- Explore full product range, videos, FAQs and purchasing steps at www.sanyoulondon.com.

Result: luxury, net-zero-ready surfaces that lower energy bills and simplify builds—without the crane weight, wall depth, or labour burden of multi-layer systems.

Share

Author

Prof. Dr. Saim Memon

PhD, CEng, FHEA, MSc, BEng(Hons), PGC-TQFE, GTCS, MCMI, MIET, MIEEE, MInstP, IBPSA, APCBEES, MPEC

CEO | Industrial Professor | Inventor | British Scientist | Chartered Engineer | Qualified Teacher | Chief Editor | World Speaker | Pioneer in Vacuum Insulation Energy Technologies